Anti-blue light nanometer composite monomer material and anti-blue light optical resin prepared from same

A nano-composite, anti-blue light technology, applied in the field of optical monomers and resin materials, can solve the problems of limited anti-reflection effect, complicated manufacturing process, fading, etc., and achieve simple and effective manufacturing process, huge application potential, and simple manufacturing process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

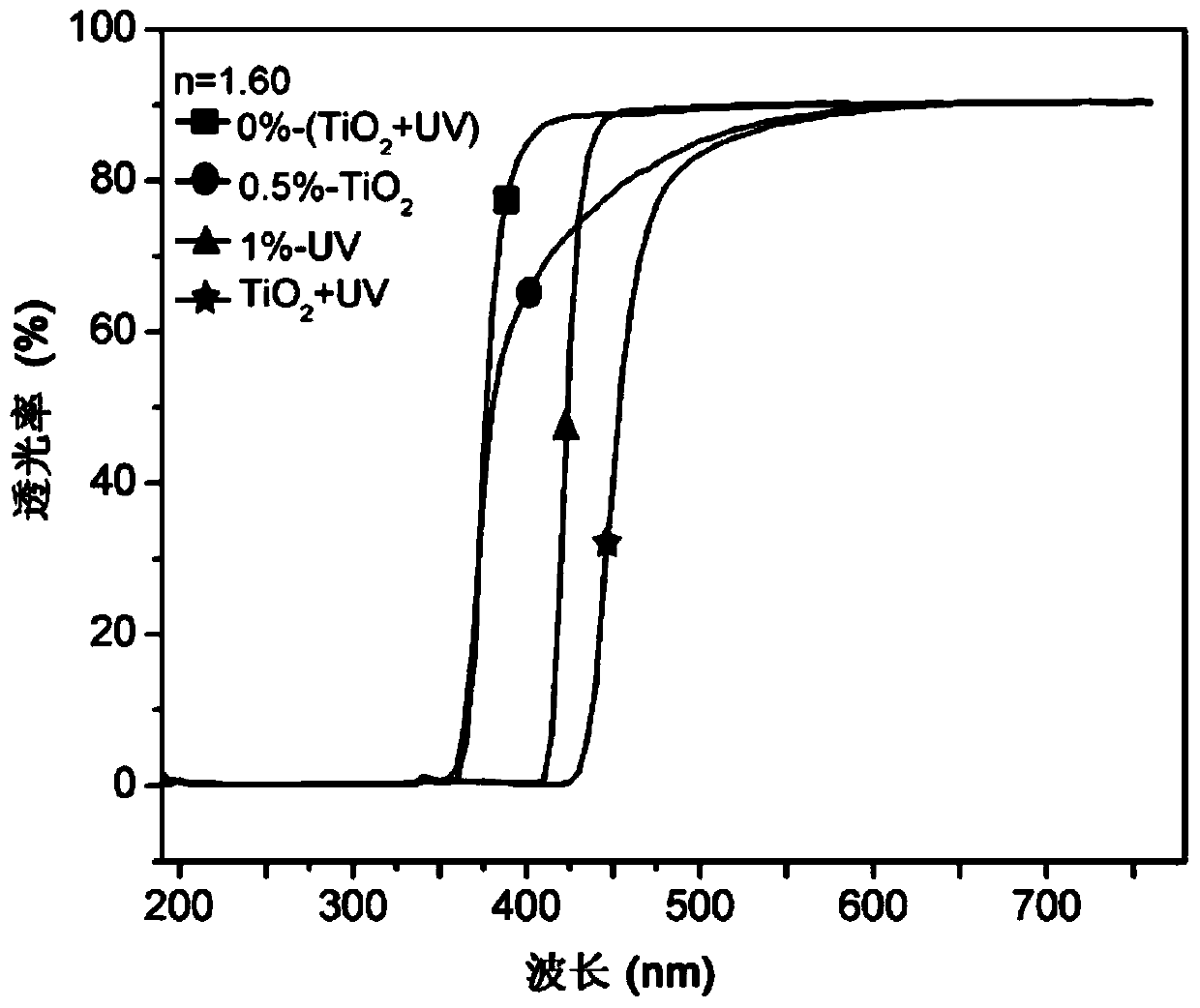

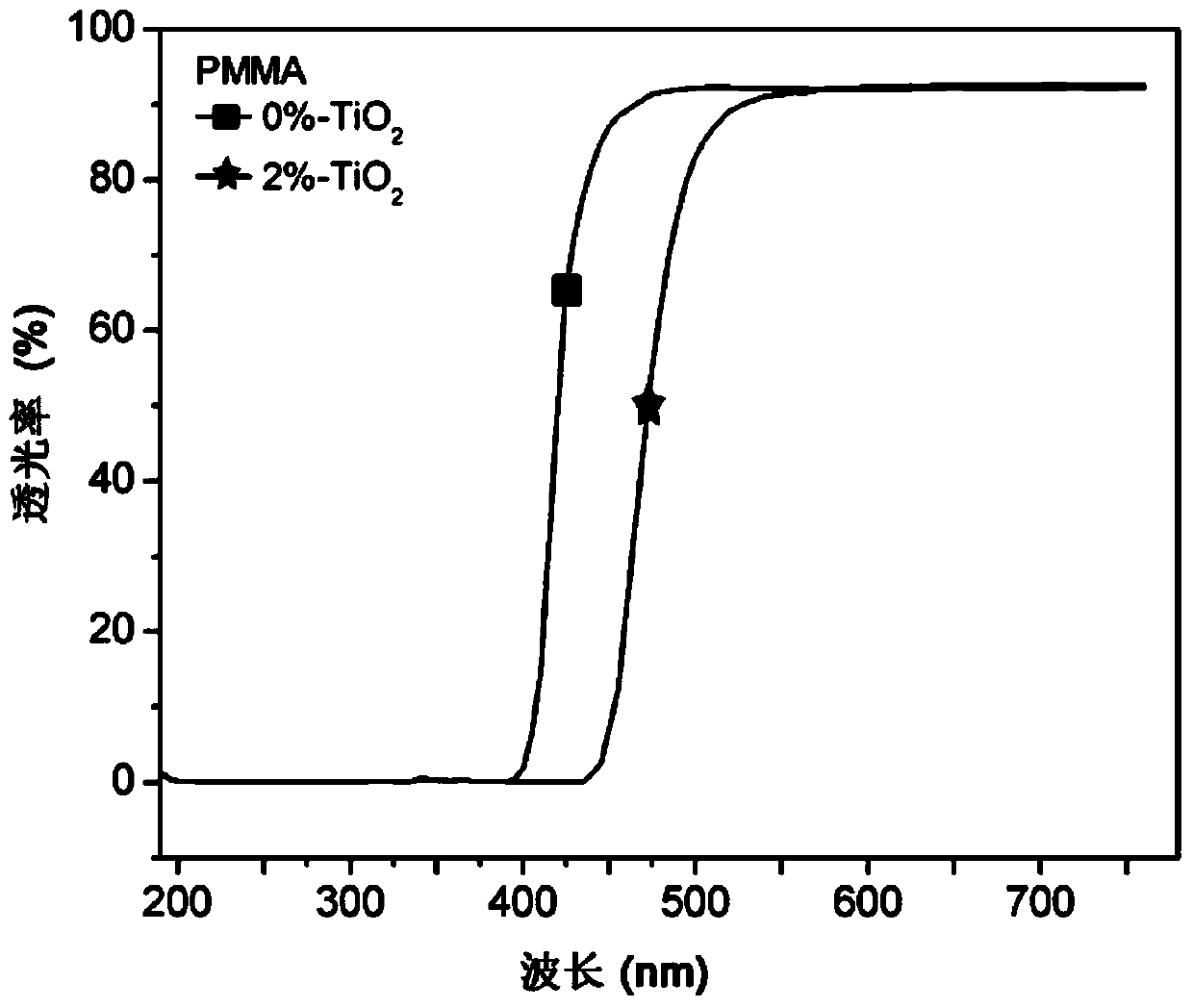

[0048] Embodiment 1 prepares anti-blue light PMMA / TiO 2 Composite resin sheet

[0049] Weigh 2.0g of titanium dioxide nanoparticles and add them to 100g of methyl methacrylate monomer, stir magnetically, disperse evenly and filter through 0.45μm filter paper, add 2.0g of ultraviolet absorbers (1.0g each of UV-328 and UV-329), After stirring and mixing evenly, add 1.0 g of initiator dibenzoyl peroxide, stir at a low speed of 200 r / min, and control the polymerization reaction at 80 ° C for 3 hours to complete the pre-polymerization; filter the pre-polymerization mixture through a 1 μm filter and degas After injection into the mold, the thickness of the mold is 3mm. After 20 hours in the curing furnace, the temperature is raised from room temperature to 85°C to complete the first curing; after the first curing is completed, the mold is opened and cleaned, and the temperature is maintained at 120°C in the precision curing furnace for 2 hours to complete the second curing. After s...

Embodiment 2

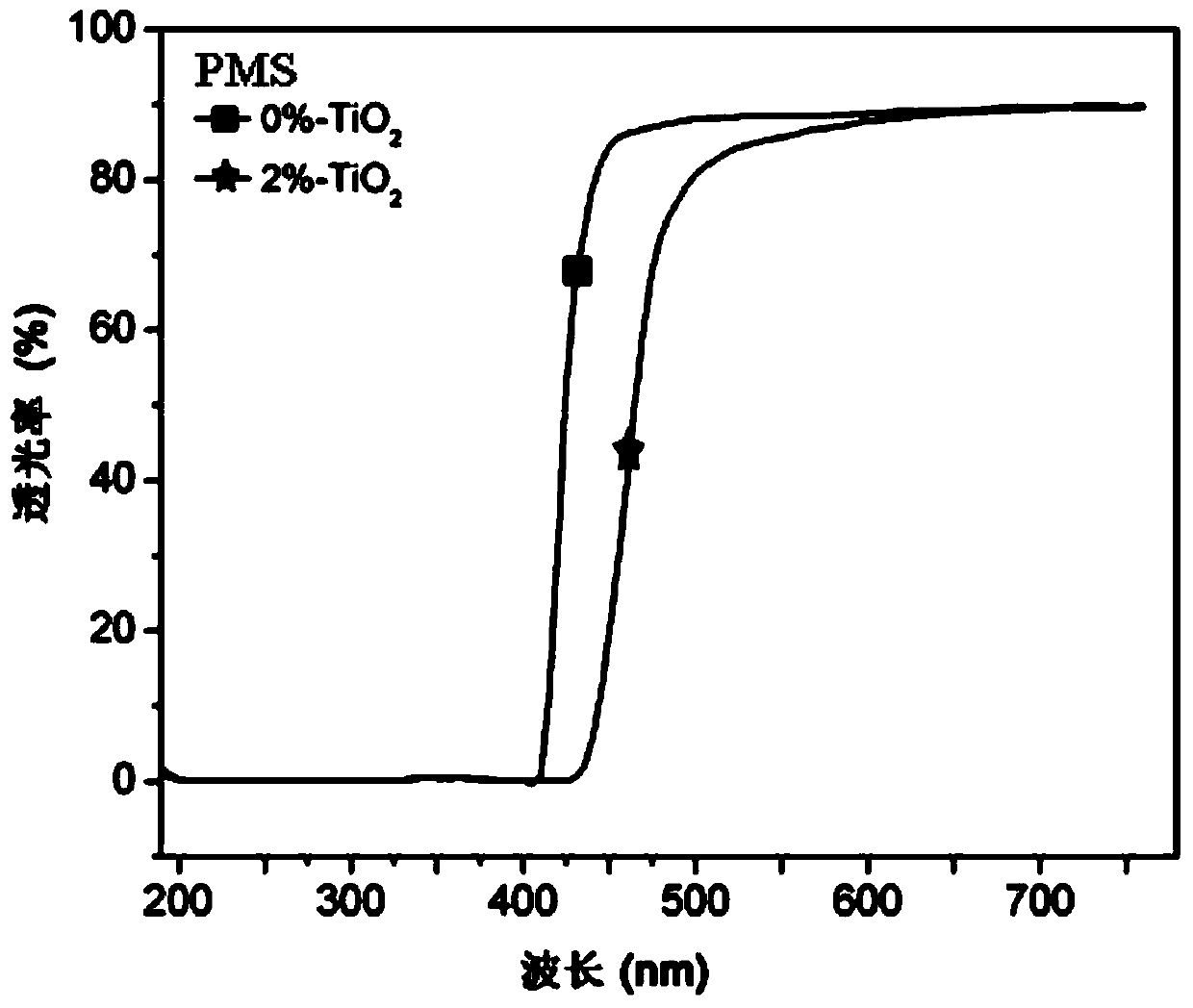

[0052] Example 2 Preparation of anti-blue light PMS / TiO 2 Composite resin sheet

[0053] Weigh 2.0g titanium dioxide nanoparticles and add them to the mixed monomer of 10g methyl methacrylate and 90g styrene, magnetically stir, disperse evenly and filter through 0.45 μm filter paper, add 2.0g ultraviolet absorber (UV-326 and UV- 327 each 1.0g), after stirring and mixing evenly, add 1.0g of initiator azobisisobutyronitrile, stir at a low speed at 200r / min, control the polymerization reaction at 80°C for 3 hours, and complete the prepolymerization; pass the prepolymerization mixture through 1μm After filtering and degassing, pour into the mold. The thickness of the mold is 3mm. After 20 hours in the curing furnace, it rises from room temperature to 85°C to complete the first curing; after the first curing is completed, the mold is opened and cleaned, and the temperature is 120°C in the precision curing furnace. The temperature was kept constant for 2 hours to complete the secon...

Embodiment 3

[0056] Example 3 Preparation of anti-blue light PMS / TiO 2 Composite resin sheet

[0057] Weigh 2.0g titanium dioxide nanoparticles and add them to the mixed monomer of 50g methyl methacrylate and 50g styrene, magnetically stir, disperse evenly and filter through 0.45 μm filter paper, add 2.0g ultraviolet absorber (UV-326 and UV- 327 each 1.0g), after stirring and mixing evenly, add 1.0g of initiator azobisisobutyronitrile, stir at a low speed at 200r / min, control the polymerization reaction at 80°C for 3 hours, and complete the prepolymerization; pass the prepolymerization mixture through 1μm After filtering and degassing, pour into the mold. The thickness of the mold is 3mm. After 20 hours in the curing furnace, it rises from room temperature to 85°C to complete the first curing; after the first curing is completed, the mold is opened and cleaned, and the temperature is 120°C in the precision curing furnace. The temperature was kept constant for 2 hours to complete the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com