Preparation method of composite cathode material SiOx@Si/C for lithium ion battery

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as hindering practical application, low theoretical specific capacity, and poor electronic conductivity, and achieve excellent electrochemical performance and stable cycle performance. , the effect of suppressing volume expansion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

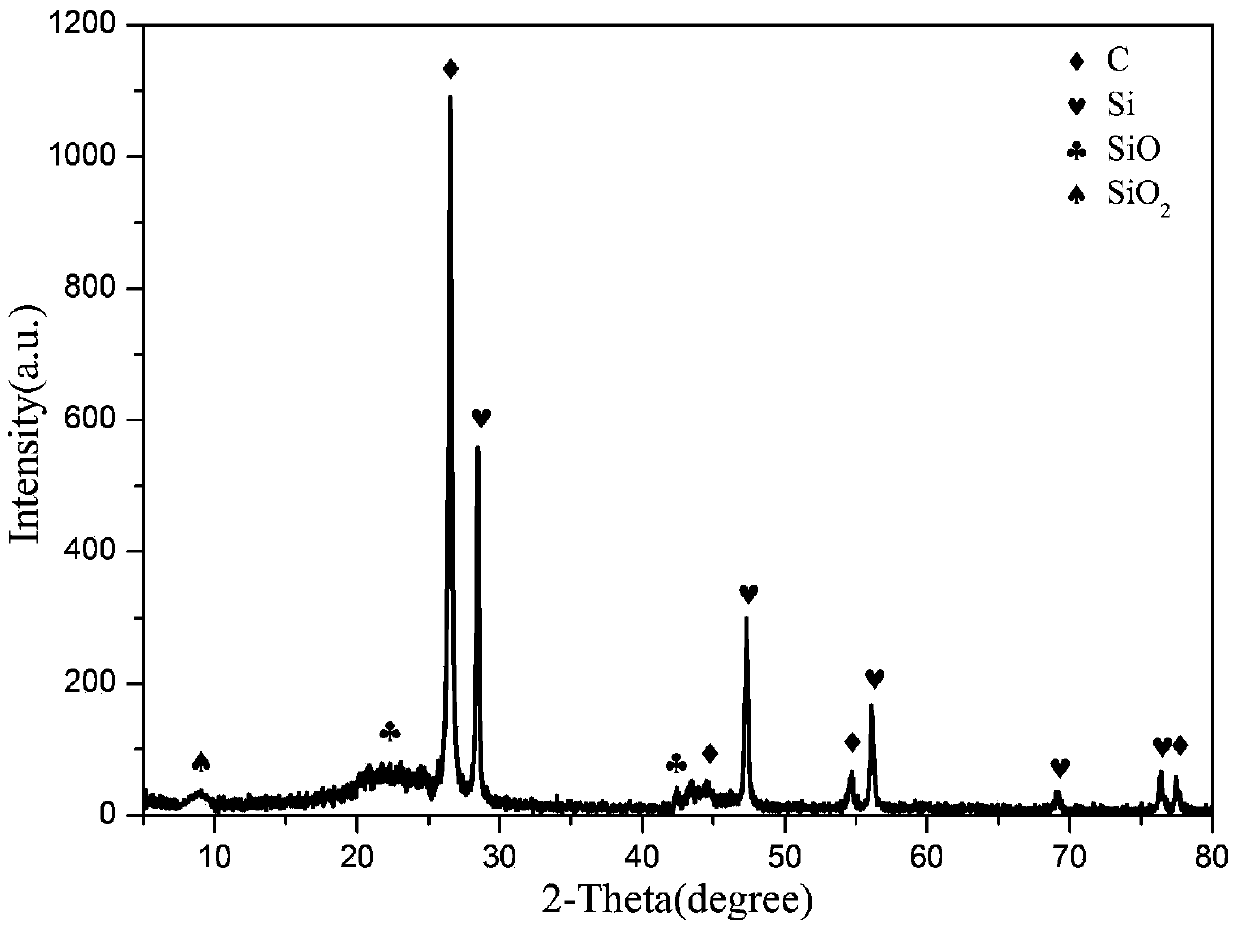

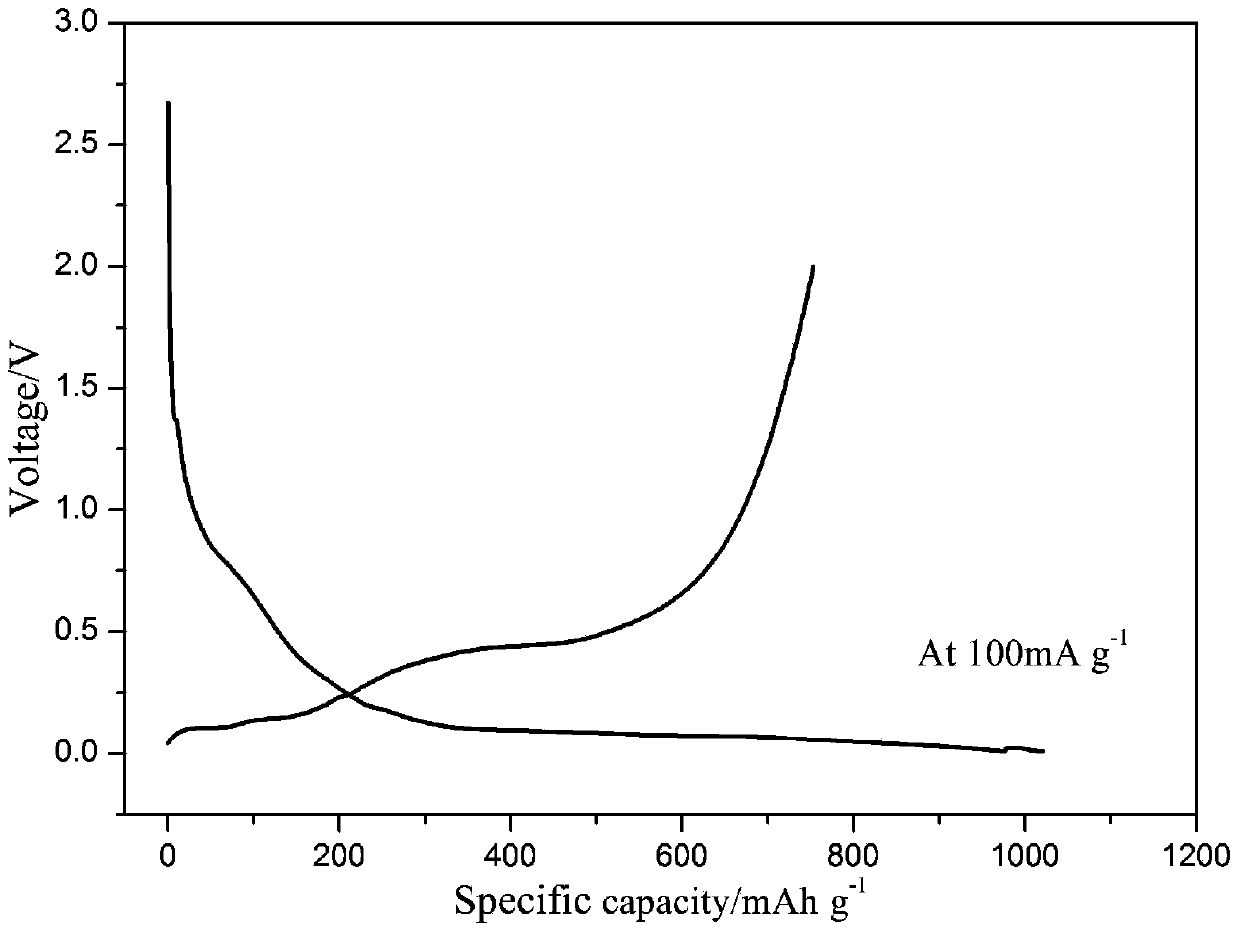

[0025] Use tetraethyl orthosilicate as the silicon source, place the silicon source in an aqueous solution of ethanol, silicon source: water: absolute ethanol = 1:2:2; choose ammonia water as the catalyst, add it to the aqueous solution of ethanol; at 40°C Add glacial acetic acid to the aqueous solution of ethanol to adjust the pH value to 10, and after hydrolysis for 4 hours, prepare a sol solution of silicon oxide; add the dispersant polyvinylpyrrolidone to the obtained sol solution, stir, and then add nano silicon powder and sucrose , silicon source: sucrose: nano silicon powder = 2: 4: A, wherein: A = 0.3, 0.5, 0.7, 0.9; continue to stir; the resulting solution is centrifuged and vacuum dried to obtain the target product SiO x Precursor of Si / C; after washing, centrifuging and vacuum-drying the obtained precursor, it is placed in an argon tube-type atmosphere furnace successively at a low temperature of 100°C for 3 hours, at a medium temperature of 400°C for 6 hours and at ...

Embodiment 2

[0031] Take vinyltrimethylsilane as the silicon source, place the silicon source in an aqueous ethanol solution, silicon source: water: absolute ethanol = 1:2:2; choose ammonium bicarbonate as the catalyst, and add it to the aqueous ethanol solution; Add glacial acetic acid to the aqueous ethanol solution at 40°C to adjust the pH to 10, and after hydrolysis for 4 hours, prepare a sol solution of silicon oxide; add the dispersant sodium dodecylsulfonate to the obtained sol solution, stir, Then add nano-silica powder and glucose, silicon source: glucose: nano-silica powder = 2:4:0.5, and continue to stir; the resulting solution is centrifuged and vacuum-dried to obtain the target product SiO x Precursor of Si / C; after washing, centrifuging and vacuum-drying the obtained precursor, it is placed in an argon tube atmosphere furnace successively according to different low temperatures of 50°C, 100°C, 150°C and 200°C for 3 hours, and the medium temperature is 400°C. ℃ for 6 hours and...

Embodiment 3

[0037] Use tetraethyl orthosilicate as the silicon source, place the silicon source in an aqueous solution of ethanol, silicon source: water: absolute ethanol = 1:2:2; choose ammonia water as the catalyst, add it to the aqueous solution of ethanol; at 40°C Add glacial acetic acid to the aqueous solution of ethanol to adjust the pH value to 10, and after hydrolysis for 4 hours, prepare a sol solution of silicon oxide; add the dispersant triethanolamine to the obtained sol solution, stir, and then add nano silicon powder and urine aldehyde Resin, silicon source: urea-formaldehyde resin: nano-silica powder = 2:4:0.5, continue to stir; the resulting solution is centrifuged and vacuum-dried to obtain the target product SiO x Precursor of Si / C; after washing, centrifuging and vacuum drying, the resulting precursor is placed in an argon tube atmosphere furnace and kept at a low temperature of 100°C for 3 hours, with different medium temperatures of 300°C, 400°C, 500°C and 600°C ℃ for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com