Rolled oil sludge purifying method

A technology for rolling sludge and oil residue, applied in the direction of lubricating composition, etc., can solve the problems of inability to dispose of oxidized and deteriorated waste oil, acid residue and waste gas to pollute the environment, and the color of regenerated oil is dark, so as to achieve saving in dosage, low cost, and regeneration. short time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0067] The rolling oil sludge is taken from the DMS20-roll reversible cold rolling unit of a steel enterprise cold rolling plant. The solid phase is 10%, and the oil sludge is dried. It is found that the elemental composition is mainly Si, Ca, Fe, Cr, Ni, Al, and contains trace elements such as Mg, Zn, Pb, P (the sum of the contents is less than 1%). In addition, it was found in the preliminary experiment that the sedimentation of rolling sludge is poor, and the natural sedimentation height in one month is only 10%, and the solid-liquid separation is very difficult.

[0068] Get this rolling oil sludge 50L, purify by the processing step of the purification method of rolling oil sludge of the present invention:

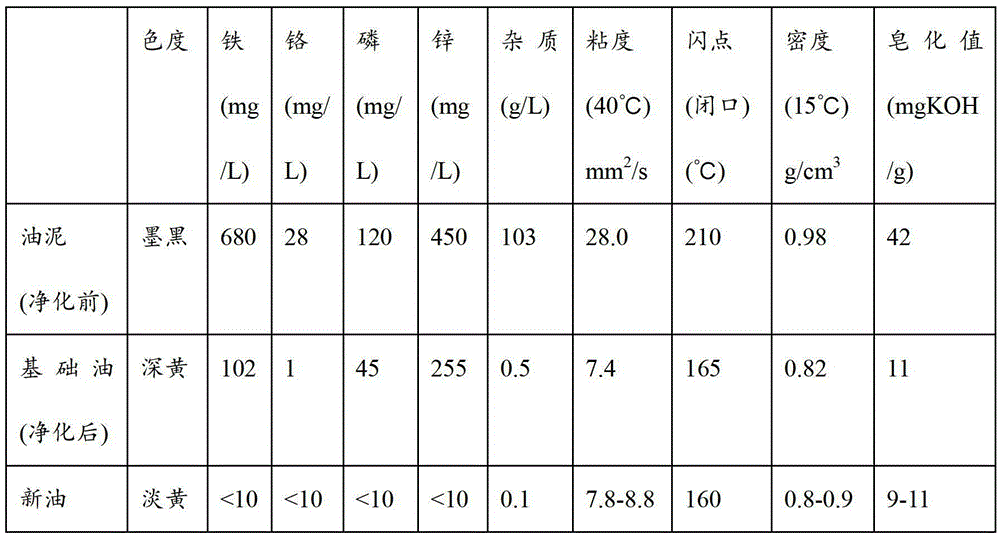

[0069] After 1 day of natural settlement of the rolling oil sludge, 3L of the upper oil liquid was obtained; the settled oil residue after the natural settlement was taken out, and 8% of the weight of the settled oil residue was added with fly ash and 2% of cement, and...

Embodiment 2

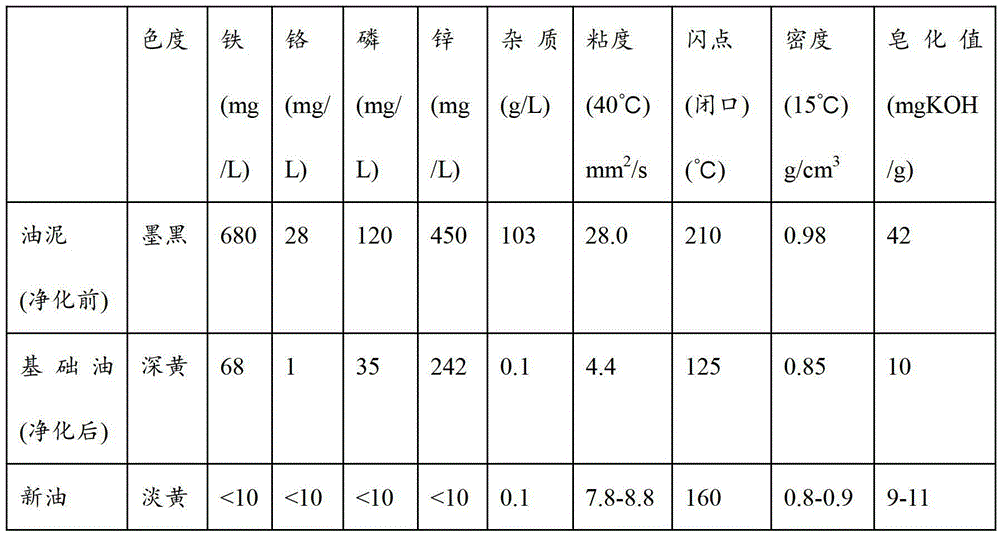

[0076] Get 50L of rolling oil sludge identical to Example 1, and purify according to the processing steps of the purification method of rolling oil sludge of the present invention: after rolling oil sludge naturally settles for 2 days, obtain 3.5L upper layer oil; The slag was taken out, and 5% coal powder of the weight of the settled oil residue was added, conditioned and tempered at a stirring speed of 400r / min for 30min, and left to stand for 1.5h; then added 0.2% polydimethyldiallylammonium chloride and 0.05% CPAM, after flocculation at a stirring speed of 50r / min for 2h, let stand for 2h.

[0077] Put the conditioned and flocculated oil residue in a high-speed tubular separator with a separation chamber volume of 50L, and centrifuge it for 15 minutes at a speed of 6000r / min. The centrifugal oil residue (about 8.5L) is discharged separately and used as honeycomb coal raw material ;Heat about 37L of centrifugal oil obtained by centrifugal separation and 3.5L of upper layer ...

Embodiment 3

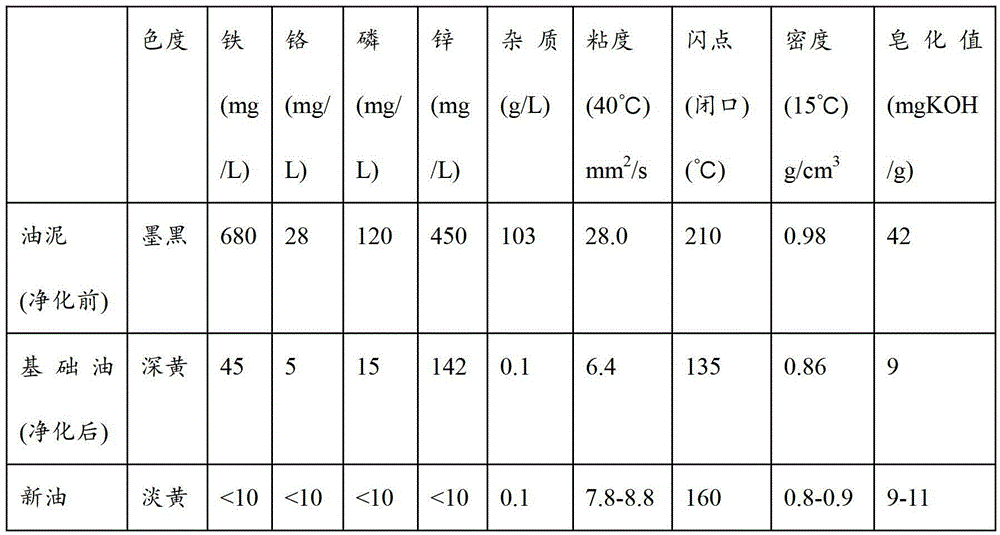

[0083] Get 50L of rolling oil sludge identical to Example 1, and purify according to the processing steps of the purification method of rolling oil sludge of the present invention: after 3 days of natural settlement of rolling oil sludge, obtain 4L upper layer oil; Take it out, add 8% quicklime of the weight of the settled oil residue, adjust and temper at a stirring speed of 300r / min for 15min, let it stand for 1h; then add 0.5% of sodium silicate and 0.5% of polyaluminum sulfate, After flocculation at the stirring speed for 1 hour, let stand for 1 hour.

[0084] Put the conditioned and flocculated oil residue in a high-speed tubular separator with a separation chamber volume of 50L, centrifuge for 30min at a speed of 4000r / min, and discharge the centrifugal oil residue (about 8L) separately for use as asphalt blending material Raw materials: about 36L of centrifugal oil obtained by centrifugation and 4L of upper layer oil obtained by natural sedimentation are heated together...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com