Automobile ceiling fabric for removing odor and preventing mold in automobile and method for preparing polymer fabric

A polymer and fabric technology, applied in the field of auto parts, can solve the problems of poor odor and mildew resistance, and achieve the effect of removing odor, good air permeability and poor water absorption in the car

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0038]In the preparation process of the polymer fabric, the polymerization reaction is carried out in a high-pressure reactor after drying and filling with nitrogen, and the pressure is preferably controlled at 9.9-10.1 MPa. The molar ratio of the silsesquioxane derivatized propylene oxide, propylene oxide and initiator is 1:5~25:0.001~0.002, preferably 1:10~20:0.001~0.002, more preferably 1: 10-15: 0.001-0.002. The mass ratio of the double metal cyanide complex to the mixture is 200-300 mg / kg. The initiator is one or more of propylene glycol, ethylene glycol, glycerol trimethylolpropane, pentaerythritol, xylitol, sorbitol, sucrose, diethylamine and diethylenetriamine.

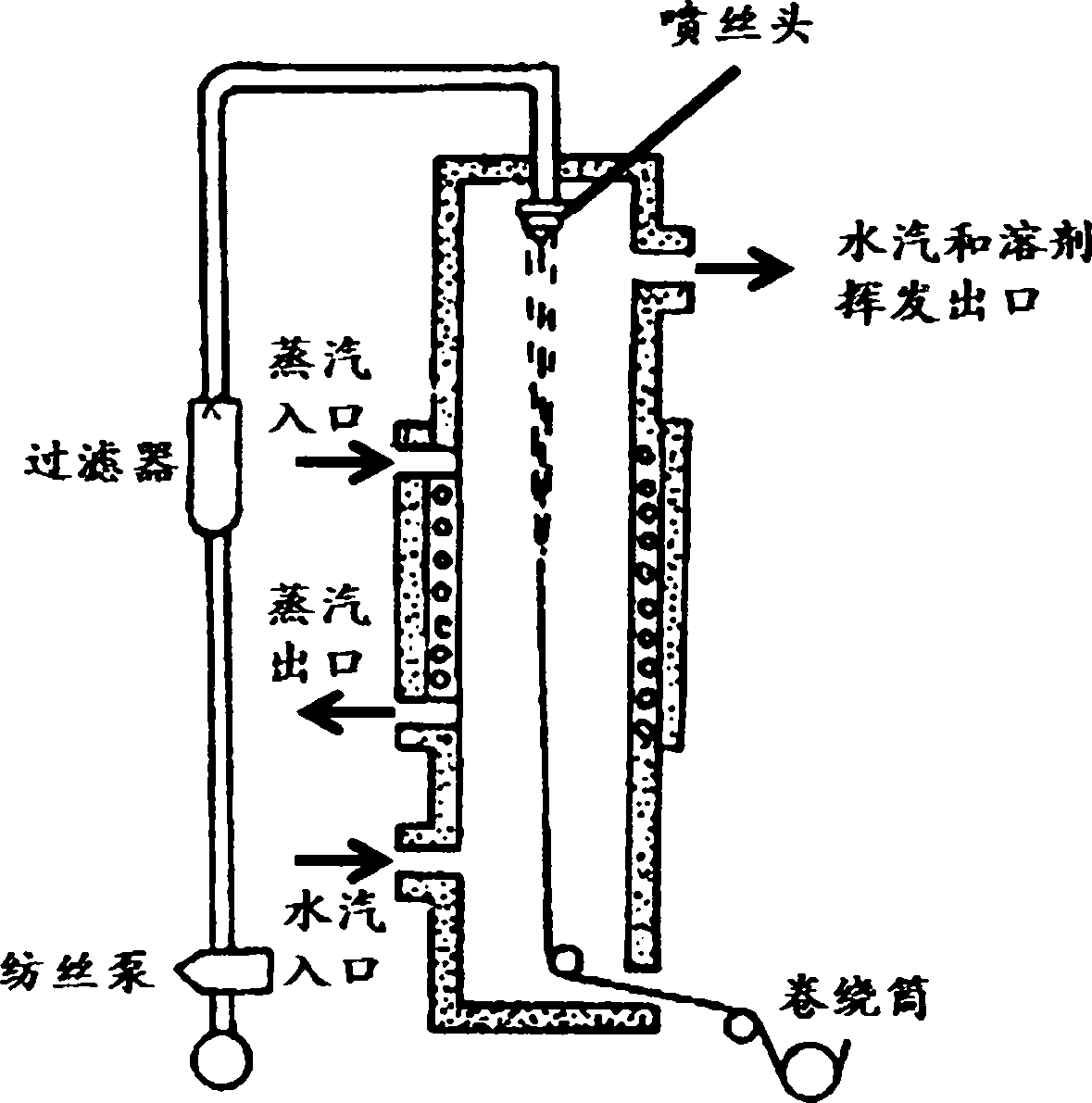

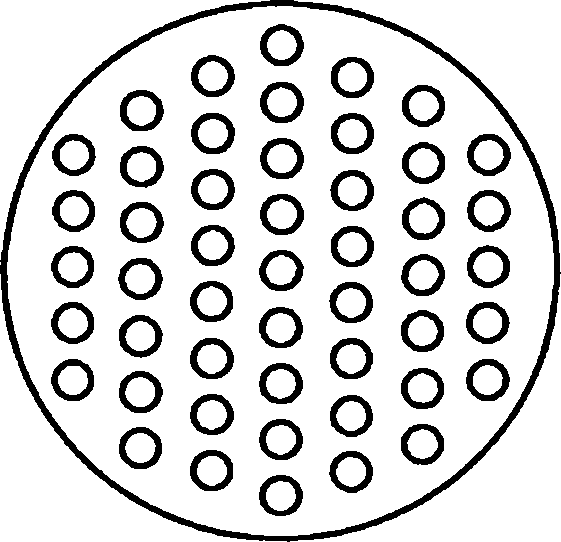

[0039] The present invention carries out spinning and spinning in ether steam and steam, and the schematic diagram of the process is as attached figure 2 As shown; the overall shape of the spinneret is circular, and the spinneret looks down as attached image 3 As shown, there are 45 to 50 nozzles on each ...

Embodiment 1

[0049] In the rapidly stirred 100mL zinc chloride-water-tert-butanol (10g zinc chloride, 75mL water, 25mL tert-butanol) mixed solution, gradually drop 20mL potassium hexacyanocobaltate-water-tert-butanol mixed solution ( 24.5g potassium hexacyanocobaltate, 15mL water, 5mL tert-butanol), about 100min to complete the dropwise addition, continue the reaction for 100min, control the temperature of the reaction process at 50°C; separate the white precipitate formed by the reaction by centrifugation (8000r / min) , were washed three times with 20 mL of tert-butanol-water mixed solution, and dried in vacuum at 50 °C for 10 h to obtain a white block DMC catalyst.

[0050] The propylene oxide derivatized by silsesquioxane according to the molar feeding ratio: propylene oxide: ethylene glycol = 1: 10: 0.001 is fed into the high-pressure reactor after the dry nitrogen-filled treatment, and 250 mg of catalyst DMC is added per kilogram of feeding , control the pressure at 10±0.1MPa, control ...

Embodiment 2

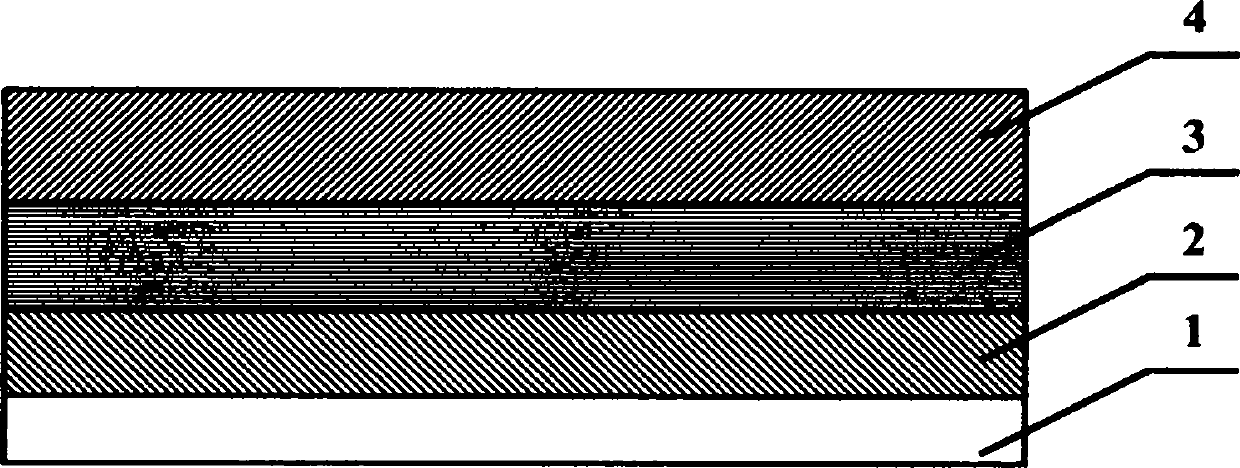

[0054] Prepare the adsorbent, the weight ratio is as follows: silica gel: diatomaceous earth: activated carbon: molecular sieve = 3: 15: 80: 5; fill the evenly mixed adsorbent into the linen bag, and sew the linen bag around tightly after filling. The final thickness of the odor absorption layer is 1.05cm; the odor absorption layer is attached to the sponge layer and the mesh layer with Velcro, and the thickness of the sponge layer is 1cm; then the new polymer woven layer is bonded to the mesh layer with waterproof glue, The amount of waterproof glue is calculated according to the area of the fabric 1L / m 2 , The gluing method is manual gluing, and after gluing, it is air-dried at room temperature and bonded. The finished product can be obtained by air drying at room temperature. The waterproof glue was purchased from Shanghai Suao Chemical Co., Ltd., model SA-1002.

[0055] Assemble the finished car roof fabric on the 2013 Geely Automobile 1.5L manual elite model, then put...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com