A kind of nanocomposite material and preparation method thereof

A nano-composite material and nano-silicon technology, applied in separation methods, chemical instruments and methods, and other chemical processes, can solve problems such as small adsorption capacity, uncontrollable pore structure of adsorbents, and small specific surface area, and achieve simple characterization methods , good CO2 adsorption performance, and the effect of mild reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

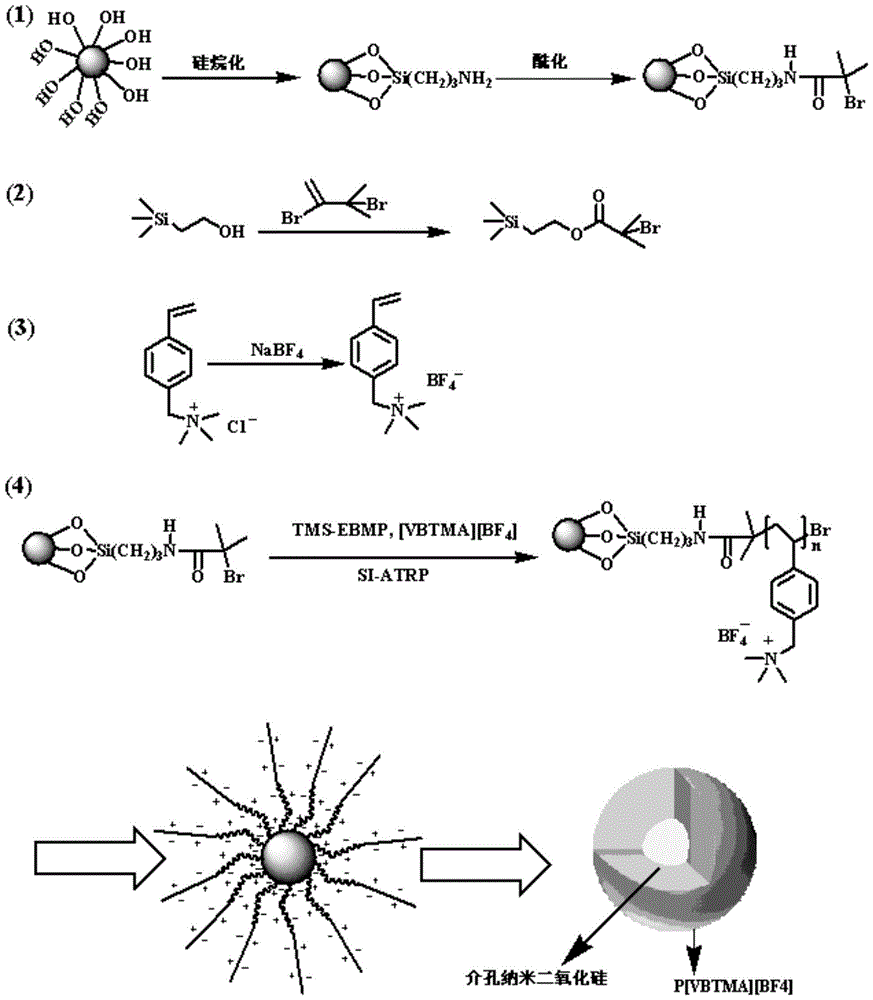

[0050] The organic-inorganic nanocomposite material in this example is prepared through the following steps:

[0051] 1) Preparation of mesoporous nano-silica atom transfer radical surface initiator:

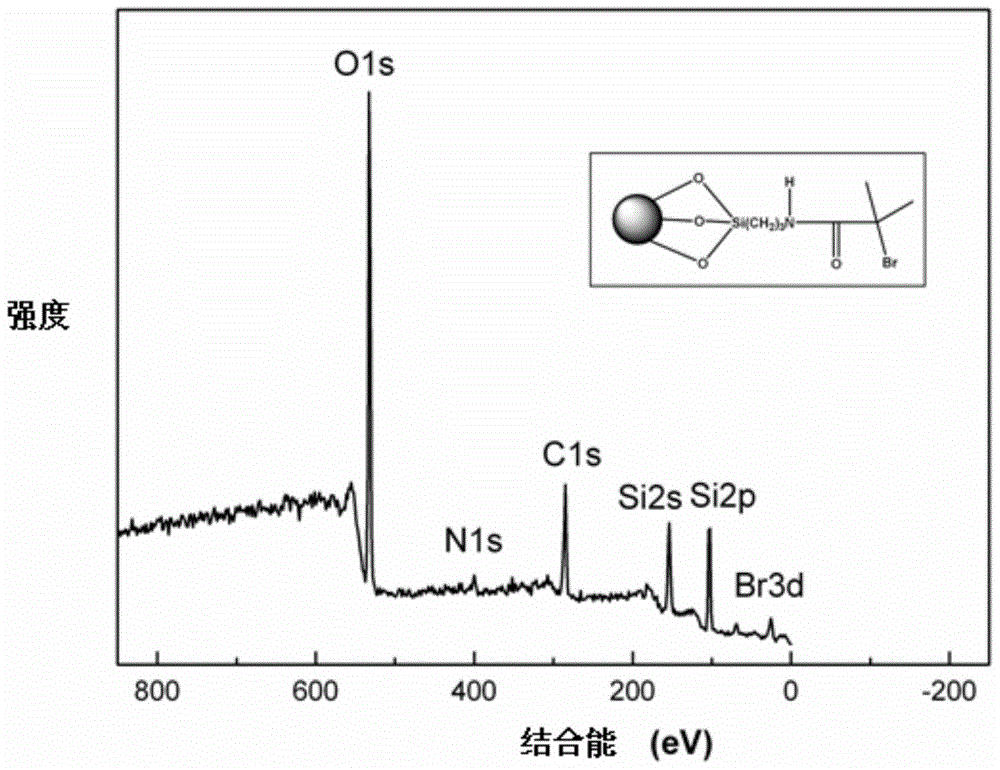

[0052] a) First, add 1 part of mesoporous nano-silica in the reactor according to the mass ratio, dissolve it with toluene, and disperse it ultrasonically. After sealing, vacuumize the reactor and pass high-purity nitrogen, and add 1 part of 3 -Aminopropyltrimethoxysilane, reflux reaction at 80°C in an oil bath for 12 hours; centrifuge the product, pour off the upper solvent, wash it with toluene and acetone ultrasonically in turn, remove the adsorbed silane coupling agent, and dry it under vacuum at 45°C A silane coupling agent-modified nano silicon dioxide is obtained.

[0053] b) Add 1 part of nano-silica modified by silane coupling agent into the reactor according to the mass ratio, dissolve it with toluene, disperse it ultrasonically, vacuumize the reactor after sealing an...

Embodiment 2

[0065] In this embodiment, the organic-inorganic nanocomposite material has the following differences from Example 1 through the following steps, and all the others are the same:

[0066] 3 parts of 3-aminopropyltrimethoxysilane in step a) of step 1), 1.5 parts of triethylamine in b) and 2.16 parts of 2-bromoisobutyryl bromide;

[0067] Step 2) 3 parts of 2-bromoisobutyryl bromide;

[0068] Step 3) sodium fluoroborate is 3 parts;

[0069] Step 4) 1.5 parts of CuCl, 1.5 parts of 1,1,4,7,7-pentamethyldiethylenetriamine, 0.1 parts of TMS-EBMP, ionic liquid monomer (p-vinylbenzyl)- Trimethyl ammonium tetrafluoroborate is 100 parts.

[0070] Measure the molecular weight M of the surface polymer of the composite material obtained by sacrificing the initiator method in the present embodiment n,NMR for 8160.

Embodiment 3

[0072] In this embodiment, the organic-inorganic nanocomposite material has the following differences from Example 1 through the following steps, and all the others are the same:

[0073] The reaction temperature in a) of step 1) is 120°C, the reflux time is 24 hours, and the reaction temperature in step b) is 30°C and the reaction time is 30 hours;

[0074] In step 2), the reaction temperature is 30° C. and the reaction time is 30 hours;

[0075] In step 3), the reaction temperature is 30° C. and the reaction time is 24 hours;

[0076] Step 4) The reaction temperature is 85°C and the reaction time is 12 hours.

[0077] Measure the molecular weight M of the surface polymer of the composite material obtained by sacrificing the initiator method in the present embodiment n,NMR for 6581.

PUM

| Property | Measurement | Unit |

|---|---|---|

| adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com