Copper-based microporous composite molecular sieve-based catalyst for FCC (fluid catalytic cracking) regenerated flue gas denitration, and preparation method and application thereof

A composite molecular sieve and regeneration flue gas technology, which is applied in the field of FCC regeneration flue gas denitrification, preparation, and copper-based microporous composite molecular sieve-based catalysts for FCC regeneration flue gas denitrification, which can solve the problem of limiting product and reactant diffusion, increasing reaction rate, etc. problems, to achieve high reactivity and selective catalytic reduction rate, low silicon-aluminum ratio, and strong chemical stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

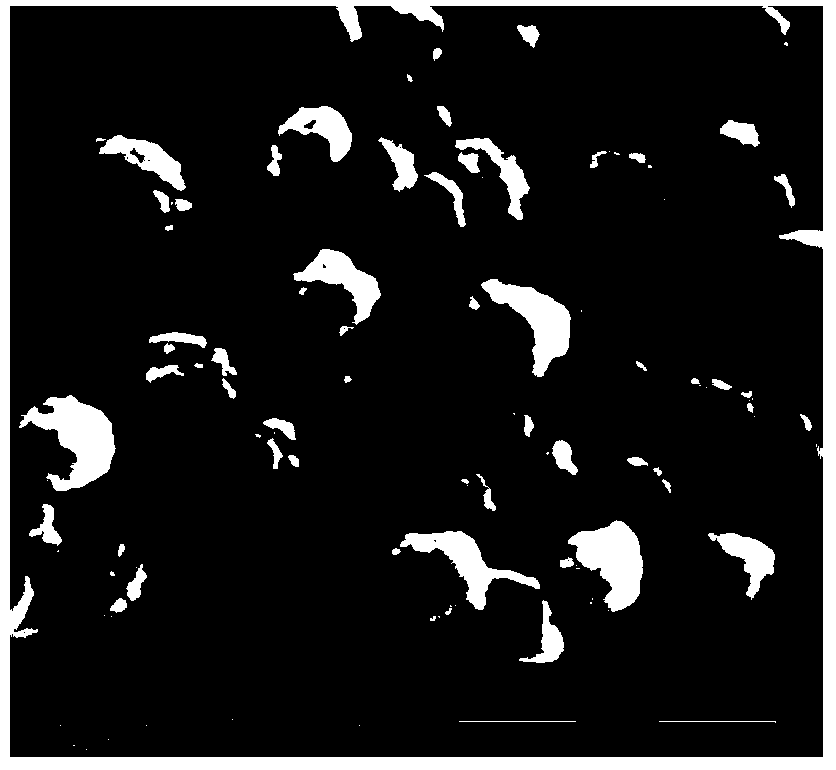

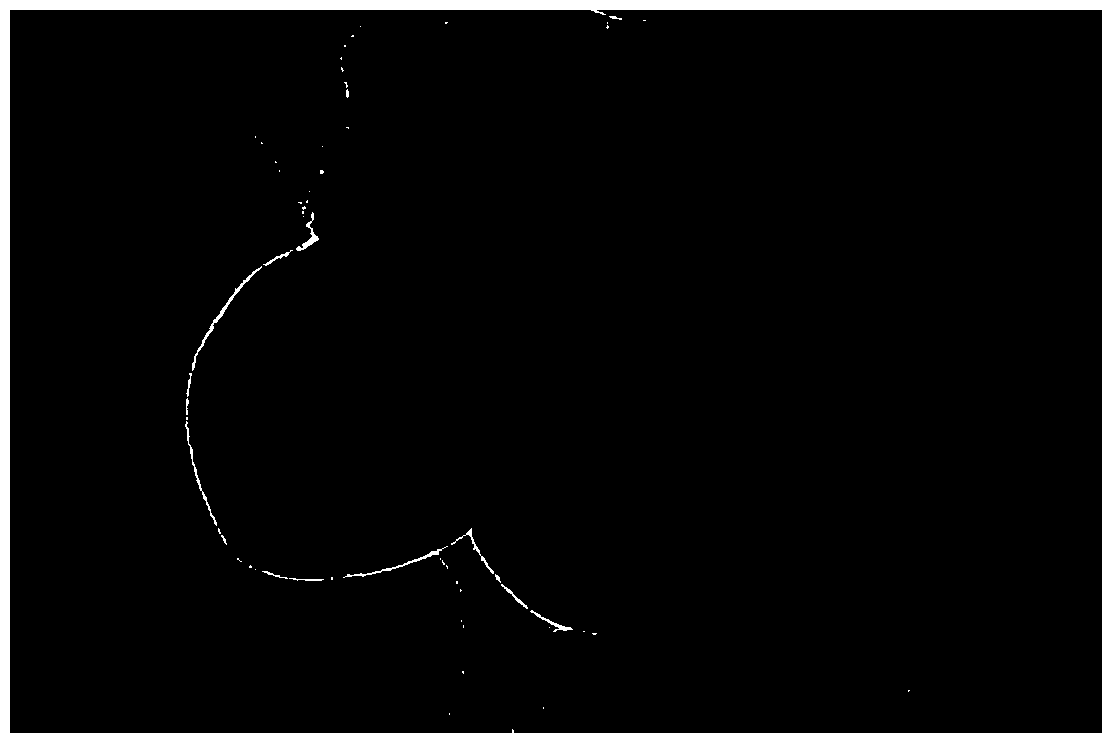

Image

Examples

Embodiment 1

[0059] Preparation of Example 1 ZSM-5 sample (Si / Al=15, Cu load=4%wt)

[0060] First, 27.3792g of tetrapropylammonium hydroxide (25%) was added to 10.8198g of deionized water, fully stirred for 30-60min, then 0.3820g of aluminum isopropoxide was added to the solution, after stirring for 30-60min, 20.0332g Add tetraethyl orthosilicate into the solution, stir for 8-16 hours, put it into a crystallization kettle, crystallize at 120°C for 32 hours, then centrifuge the reaction product, and then wash the lower layer of solid with alcohol, repeat twice , dried at 100°C for 12h, and calcined at 550°C for 6h to obtain a nanoscale ZSM-5 carrier. Subsequently, 0.7604g Cu(NO) 3 ·3H 2O Dissolve the salt containing the required heteroatoms in 3g of deionized water, add 5g of nano-sized ZSM-5 molecular sieve after it is completely dissolved, stir evenly, ultrasonically clean for 30-40min, dry at 100°C for 12h, and roast at 550°C for 6h to get the final product.

Embodiment 2

[0061] Preparation of Example 2 Cu / ZSM-5 / SAPO-34 sample (m=SAPO-34 / ZSM-5=1, Cu load=4%w)

[0062] First, add 24.2707g of tetraethylammonium hydroxide into 1.3151g of deionized water, stir for 30-60min, then add 3g of pseudo-boehmite into the solution, stir for 30-60min, then add 4.7479g of phosphorus source into the In the solution, stir for 30-60min, then add 1.8563g of silica sol into the solution, stir for 5-10h, add 4.63g of nano-sized ZSM-5 seeds, put it into a crystallization kettle, and crystallize at 200°C After 72 hours, the reaction product was centrifuged, dried at 100° C. for 12 hours, and calcined at 550° C. for 6 hours to obtain a nanoscale ZSM-5 / SAPO-34 carrier. Subsequently, dissolve 0.7604g of Cu(NO)3 3H2O salt containing the desired heteroatom into 3g of deionized water, add 5g of ZSM-5 / SAPO-34 after complete dissolution, stir evenly, and ultrasonically clean for 30- 40min, drying at 100°C for 12h, and calcination at 550°C for 6h to obtain the final product....

Embodiment 3

[0064] First, tetrapropylammonium hydroxide (25%) was added to deionized water, fully stirred for 30-60min, then aluminum isopropoxide was added to the solution, after stirring for 30-60min, tetraethyl orthosilicate was added to In solution, wherein control reaction raw material add-on, make tetrapropyl ammonium hydroxide: Al 2 o 3 :SiO2 2 :H 2 The molar ratio of O and four is 9:0.25:5:500. After stirring for 8-16 hours, put it into a crystallization tank, crystallize at 90°C for 24 hours, then centrifuge the reaction product, and then wash the lower layer solid with alcohol. After repeating twice, dry at 90°C for 24h, and bake at 500°C for 8h to obtain nanoscale ZSM-5 carrier.

[0065] First, add the template agent tetraethylammonium hydroxide into deionized water, stir for 30-60min, then add pseudoboehmite into the solution, stir for 30-60min, then add the phosphorus source into the solution, stir for 30-60min , then, add silica sol to the solution, control the amount of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com