Method for preparing different colors of mixed phase nano TiO2

A mixed phase and color technology, applied in chemical instruments and methods, titanium oxide/hydroxide, physical/chemical process catalysts, etc., can solve the problems of high natural cost, harsh experimental conditions, complicated steps, etc., and achieve low cost , The preparation process is simple, and the effect of light absorption enhancement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

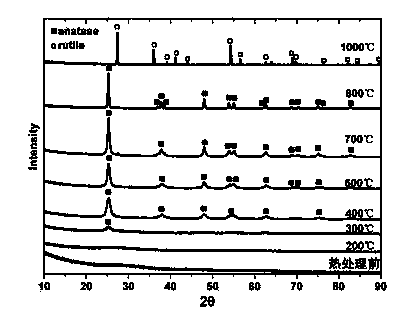

Embodiment 1

[0034] Under the condition of ice-water bath, add 12mL and 20mL prepared 8.0g / 100mL titanium sulfate solution and 4mol / L ammonia water to 100mL deionized water respectively, and magnetically stir the reaction system for 2 hours; centrifuge the stirred sol, and deionized water for solid precipitation Ultrasonic washing; take 100mL of the washed sol and dry it at 80°C to obtain white nano-TiO before heat treatment 2 solid( figure 1 ). The nano-TiO 2 Belongs to the amorphous state ( figure 2 ), no crystal structure was formed ( image 3 part a of ), the microstructure is TiO 6 octahedral aggregates, according to the quantum size effect, the TiO 2 There are only discrete energy levels, and there is no quasi-continuous band structure, so the band gap is very large ( Figure 7 ). Its specific surface area is as high as 328.55m 2 / g, so it has a strong adsorption effect on organic matter in the solution, but due to poor crystallinity and large band gap, it has almost no phot...

Embodiment 2

[0036] Under the condition of ice-water bath, add 12mL and 20mL prepared 8.0g / 100mL titanium sulfate solution and 4mol / L ammonia water to 100mL deionized water respectively, and magnetically stir the reaction system for 2 hours; centrifuge the stirred sol, and deionized water for solid precipitation Ultrasonic washing; take 100mL of the washed sol and dry it at 80°C to obtain white nano-TiO 2 solid, and then heat-treated at 200 °C for 3 h to obtain brown mixed-phase nano-TiO 2 ( figure 1 ). The nano-TiO 2 Most are amorphous ( figure 2 ), while anatase phase crystals began to nucleate, with an average particle size of 1.44nm ( image 3 part b), the specific surface area is up to 281.88m 2 / g. The TiO 2 has the highest and continuous visible light absorption ( Figure 5 ), and thus has the greatest degree of band bending, resulting in the narrowest bandgap ( Figure 7 ). The product also has a certain adsorption capacity, but due to poor crystallinity and low photocat...

Embodiment 3

[0038] Under the condition of ice-water bath, add 12mL and 20mL prepared 8.0g / 100mL titanium sulfate solution and 4mol / L ammonia water to 100mL deionized water respectively, and magnetically stir the reaction system for 2 hours; centrifuge the stirred sol, and deionized water for solid precipitation Ultrasonic washing; take 100mL of the washed sol and dry it at 80°C to obtain white nano-TiO 2 solid, and then heat-treated at 400 °C for 3 h to obtain yellow nano-TiO 2 ( figure 1 ). The nano-TiO 2 Belongs to anatase and amorphous mixed phase ( figure 2 ), the anatase phase crystals gradually grew up, and the average particle size increased to 8.90nm ( image 3 part c), the specific surface area is 161.18m 2 / g. The TiO 2 A bump appears in the visible light absorption spectrum ( Figure 5 ), indicating that it has an interband energy level ( Figure 7 ), which is also the main reason for the narrowing of its forbidden band width. The adsorption capacity of this product ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com