Preparing method of ferroferric oxide nanometer particles

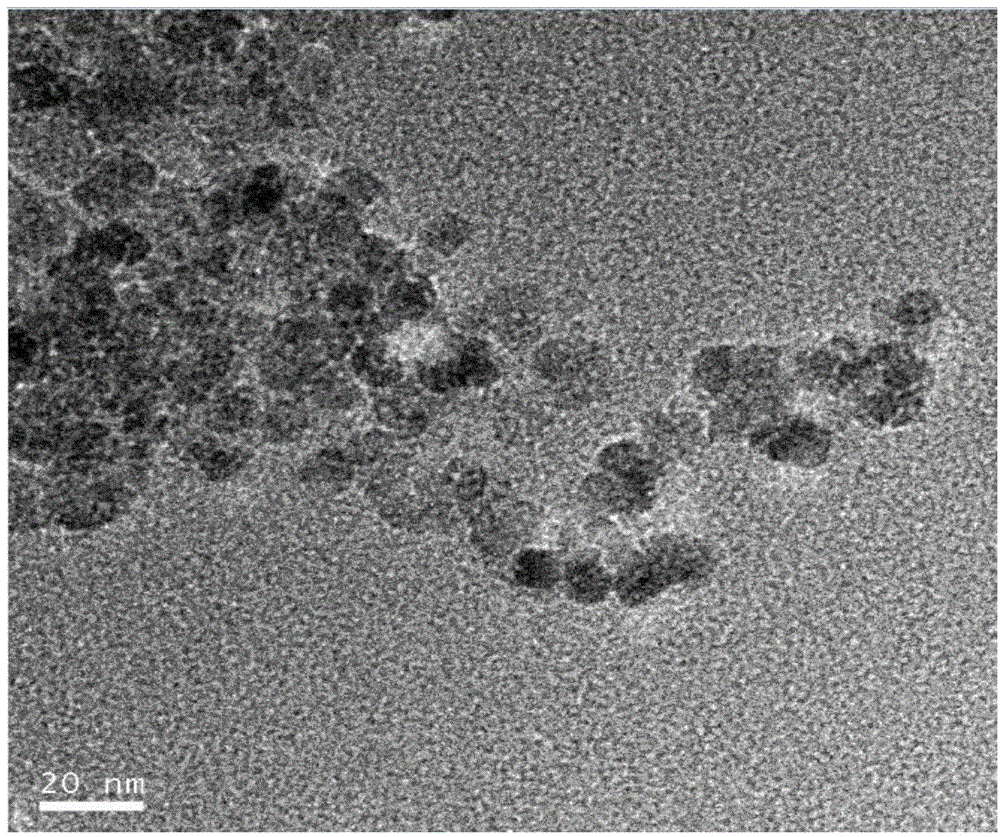

A technology of ferric oxide and nanoparticles, which is applied in the direction of iron oxide/iron hydroxide, nanotechnology, nanotechnology, etc., can solve the problems of unfavorable large-scale production, complicated preparation process, narrow particle distribution, etc., and achieve convenient large-scale The production and production process are simple to operate and the effect of small crystal particles

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

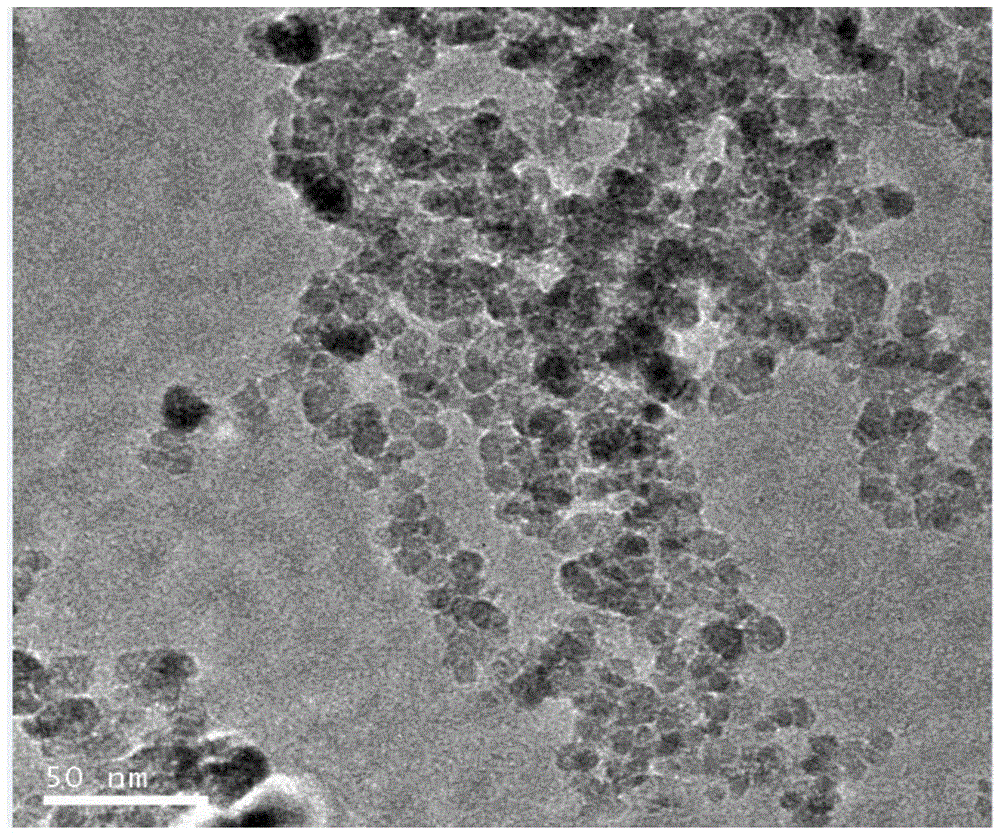

[0030] A preparation method of iron ferric oxide nanoparticles with good dispersibility, the steps of the preparation method are:

[0031] (1) Preparation of Fe3O4 nanoparticles

[0032] (1-1) Take 50mL of deionized water solution and transfer it to the reaction vessel, and pass nitrogen gas into the deionized water to eliminate the oxygen in the reaction system and the reaction vessel;

[0033] (1-2) Under a nitrogen atmosphere, add ferric chloride and ferrous sulfate in an equimolar ratio to deionized water so that the molar volume concentration of ferrous iron and ferric iron is between 0.01mol / L and 0.1mol / L time, then join [BMIN]BF 4 Ionic liquid is used as a dispersant, turn on mechanical stirring, and stir at a speed of 100-200 rpm for 10 minutes to prepare an iron source dispersion solution and heat it to 70°C for later use. The deionized water and [BMIN]BF 4 The volume ratio of the ionic liquid is 100:2-14.

Embodiment 1

[0042] A preparation method of iron ferric oxide nanoparticles with good dispersibility, the steps of the preparation method are:

[0043](1) Preparation of Fe3O4 nanoparticles

[0044] (1-1) Take 50mL of deionized water solution and transfer it to the reaction vessel, and pass nitrogen gas into the deionized water to eliminate the oxygen in the reaction system and the reaction vessel;

[0045] (1-2) In a nitrogen atmosphere, add ferric chloride and ferrous sulfate in an equimolar ratio to deionized water, so that the molar volume concentrations of ferrous sulfate containing ferrous iron and ferric chloride containing ferric iron are equal. to 0.01mol / L, then add 1mL of [BMIN]BF 4 The ionic liquid was used as a dispersant, and the mechanical stirring was turned on, and stirred at a speed of 100 rpm for 10 minutes to obtain an iron source dispersion solution, which was heated to 70°C and set aside.

[0046] (1-3) Weigh sodium hydroxide and deionized water, and prepare an aque...

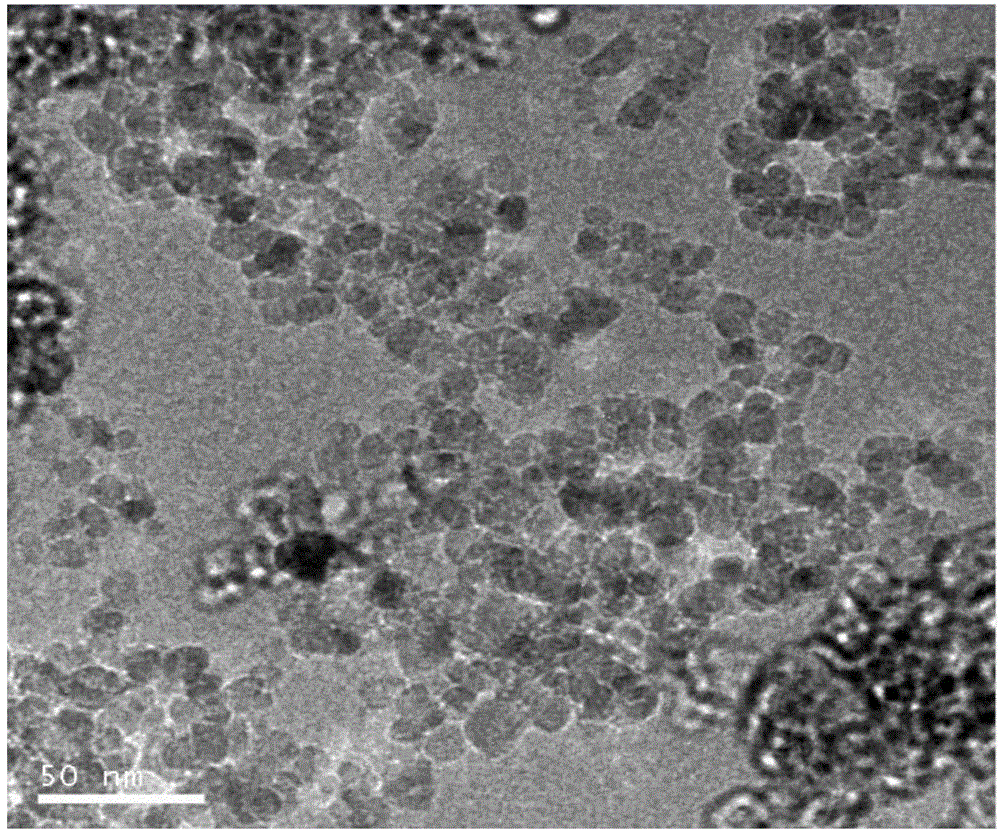

Embodiment 2

[0054] A preparation method of iron ferric oxide nanoparticles with good dispersibility, the steps of the preparation method are:

[0055] (1) Preparation of Fe3O4 nanoparticles

[0056] (1-1) Measure 50mL of deionized water solution and transfer it to the reaction vessel, and pass nitrogen gas into the deionized water to eliminate the oxygen in the reaction system and the reaction vessel;

[0057] (1-2) In a nitrogen atmosphere, add ferric chloride and ferrous sulfate in an equimolar ratio to deionized water, so that the molar volume concentrations of ferrous sulfate containing ferrous iron and ferric chloride containing ferric iron are equal. to 0.05mol / L, then add 3mL of [BMIN]BF 4 The ionic liquid was used as a dispersant, and the mechanical stirring was turned on, and stirred at a speed of 100 rpm for 10 minutes to obtain an iron source dispersion solution, which was heated to 70°C and set aside.

[0058] (1-3) Weigh sodium hydroxide and deionized water, and prepare an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com