Molybdate upconversion luminescent material, preparation method and application thereof

A luminescent material, molybdate technology, applied in luminescent materials, chemical instruments and methods, etc., can solve the problems of low luminescent purity, complex preparation process, environmental pollution, etc., and achieve high luminescent brightness, simple synthesis process, and environment-friendly. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

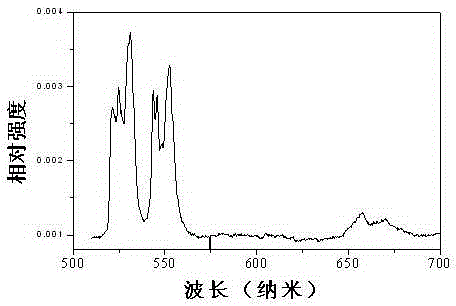

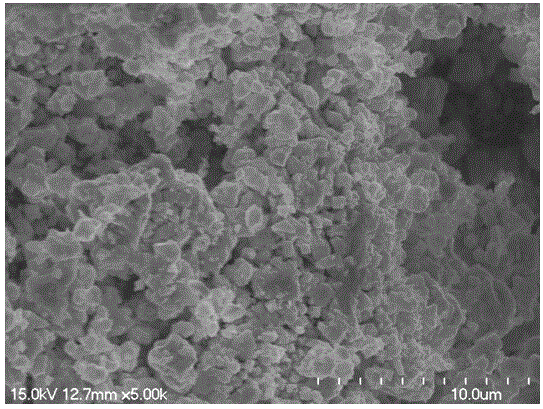

[0039] Preparation of ZnGd 2.8 Er 0.4 Yb 0.8 Mo 3 o 16

[0040] According to the chemical formula ZnGd 2.8 Er 0.4 Yb 0.8 Mo 3 o 16 The stoichiometric ratio of each element in is weighed as ytterbium oxide Yb 2 o 3 : 1.051 g, erbium oxide Er 2 o 3 : 0.51 g, zinc oxide ZnO: 0.543 g, gadolinium oxide Gd 2 o 3 : 2.11 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 ?4H 2 O: 3.53 grams. After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first pre-sintering, the pre-sintering temperature is 250 ° C, and the sintering time is 5 hours, then cool to room temperature, and take out the sample. After the pre-sintering, the mixture is fully ground again, placed in the air atmosphere, and the second calcination is carried out at 450°C for 12 hours, then naturally cooled to room temperature, the sample is taken out, and the third calcination is carried out after fully grinding , the calcination temperature is 950°C, the calcination time is...

Embodiment 2

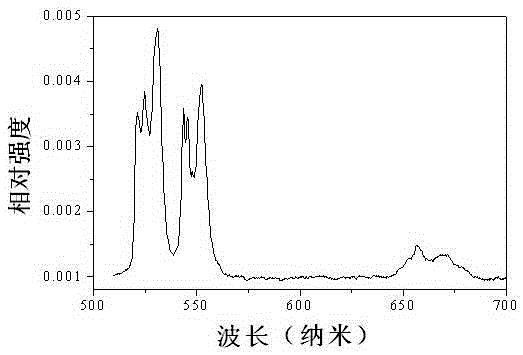

[0044] Preparation of ZnLa 0.8 Er 1.2 Yb 2 Mo 3 o 16

[0045] According to the chemical formula ZnLa 0.8 Er 1.2 Yb 2 Mo 3 o 16 The stoichiometric ratio of each element in is weighed as ytterbium oxide Yb 2 o 3 : 2.627 g, erbium oxide Er 2 o 3 : 1.53 g, zinc oxide ZnO: 0.543 g, lanthanum oxide La 2 o 3 : 0.869 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 ?4H 2 O: 3.53 grams. After grinding and mixing uniformly in an agate mortar, select the air atmosphere for the first pre-sintering, the pre-sintering temperature is 300°C, and the sintering time is 7 hours, then cool to room temperature, and take out the sample. After pre-sintering, grind the mixture fully and evenly again, put it in the air atmosphere, and carry out the second calcination. Three times of calcination, the calcination temperature is 1000°C, and the calcination time is 5 hours. After natural cooling, the powder is evenly ground to obtain a new type of molybdate up-conversion luminescent material...

Embodiment 3

[0048] Preparation of ZnTm 3 Er 0.2 Yb 0.8 Mo 3 o 16

[0049] According to the chemical formula ZnTm 3 Er 0.2 Yb 0.8 Mo 3 o 16 The stoichiometric ratio of each element in the ytterbium nitrate Yb (NO 3 ) 3 ?5H 2 O: 2.395 grams, erbium nitrate Er (NO 3 ) 3 ?5H 2 O: 0.426 grams, zinc oxide ZnO: 0.543 grams, thulium nitrate Tm (NO 3 ) 3 ?6H 2 O: 9.26 g, ammonium molybdate (NH 4 ) 6 Mo 7 o 24 ?4H 2 O: 3.53 grams, then take by weighing citric acid by 0.5wt% of each above-mentioned drug quality respectively. First, dissolve the above-mentioned raw materials weighed in an appropriate amount of nitric acid solution, stir at 50°C until completely dissolved, and dilute with 5 times its volume of deionized, and then add the weighed citric acid to each solution, and stirred under magnetic stirring for 0.5 hours. Finally, mix the obtained solutions, continue heating and stirring at 50°C for 2 hours, let stand, and dry to obtain a fluffy precursor; place the precurso...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com