Hydrophilic lubricating antibacterial lacrimal duct tube and manufacturing method thereof

A lacrimal duct and antibacterial agent technology, applied in the medical field, can solve problems such as easy extubation breakage, lacrimal duct tissue adhesion, etc., achieve the effect of improving pushability and twist control, increasing the success rate of surgery, and promoting wound healing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

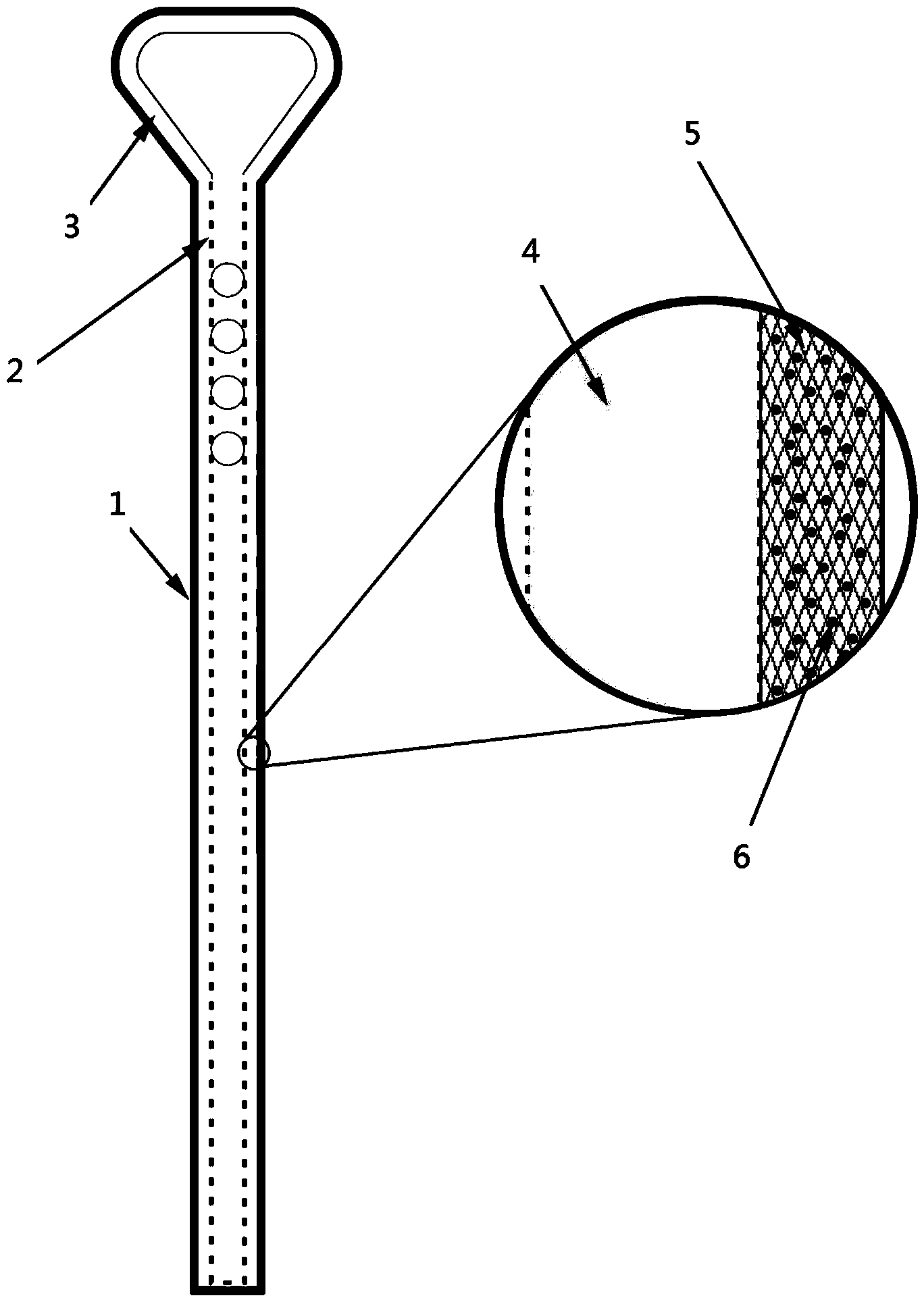

[0048] The preparation method of lacrimal duct of the present invention comprises the following steps:

[0049] (a) providing a basic lacrimal duct, the basic lacrimal duct includes a main tube body and a lifting ring tube body, wherein the upper end of the main tube body is connected to the lower end of the lifting ring tube body;

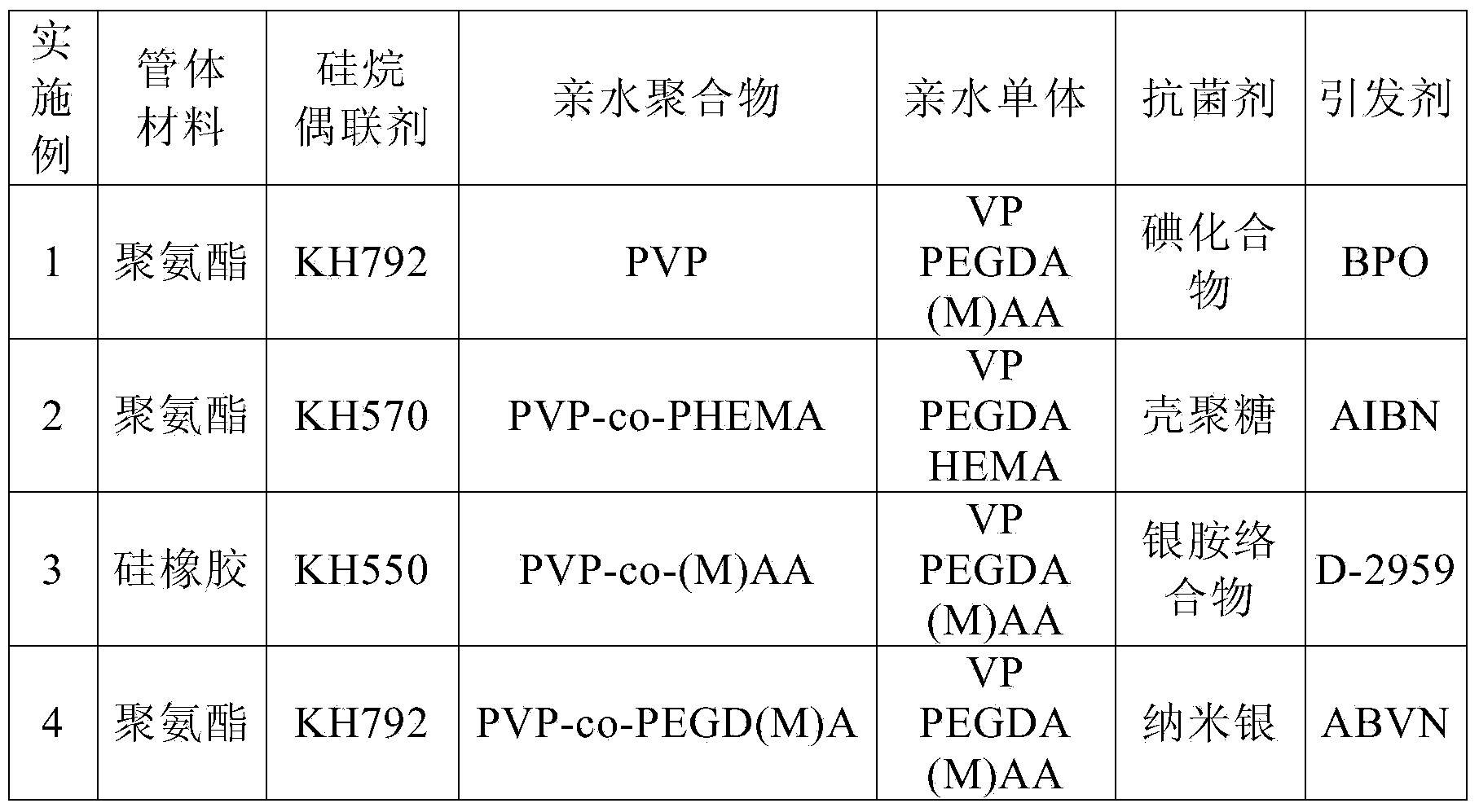

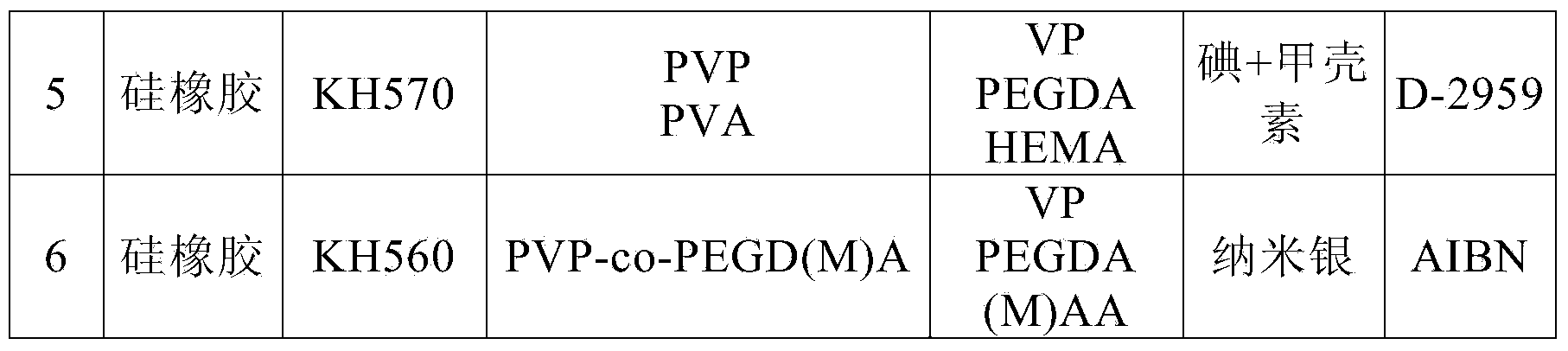

[0050] (b) The base lacrimal duct is treated with plasma treatment and silane coupling agent surface treatment in sequence, and then treated with an active reaction solution, the active reaction solution comprising: hydrophilic polymer, hydrophilic polymer monomer, antibacterial agent and Initiator;

[0051] (c) Initiating a polymerization reaction to form a composite functional layer on the tube wall of the main tube body and the pulling ring tube body, to obtain the lacrimal duct tube according to claim 1.

[0052] The hydrophilic lubricating antibacterial lacrimal duct prepared by the method has a uniform surface coating (composite functional ...

Embodiment 1

[0114] Prepare a solution of silane coupling agent KH792 with a concentration of 3% (w / w), use a mixed solution of ethanol and dichloromethane as the solvent, clean and dry the polyurethane-based lacrimal duct, and place it in the above-mentioned silane coupling agent solution Soak for 60 minutes, take it out and dry it naturally, and then put it in an oven at 120°C for 3 hours.

[0115] Prepare the active reaction solution: the solvent is a mixed solvent of methanol, dichloromethane and tetrahydrofuran, and the concentration of the active reaction solution is 6% (w / w), wherein PVP:VP:PEGDA:(M)AA=80:10:3:7 (weight ratio), the content of the iodine compound (iodophor) available iodine component is 1% (w / w), and the content of the initiator BPO is 0.5% (w / w).

[0116] Soak the above-mentioned basic lacrimal duct treated with silane coupling agent in the above-mentioned active reaction solution, react for 60 minutes, take it out, dry it for 30 minutes under the protection of nitr...

Embodiment 2

[0120] Prepare a solution of silane coupling agent KH570 with a concentration of 4% (w / w), use ethanol solution as the solvent, clean and dry the polyurethane-based lacrimal ducts, soak in the above-mentioned silane coupling agent solution for 40 minutes, and take it out Let it dry naturally, and then put it in an oven at 120°C for 3 hours.

[0121] Prepare active reaction solution: the solvent adopts the mixed solvent of methanol, cyclohexane, dimethylformamide and acetic acid, and the system concentration is 5% (w / w), wherein PVP-co-PHEMA:VP:PEGDA:HEMA=70: 15:5:10 (weight ratio), chitosan concentration is 2% (w / w), and initiator AIBN content is 1.0% (w / w).

[0122] Soak the above-mentioned basic lacrimal duct treated with silane coupling agent in the above-mentioned active reaction solution, react for 80 minutes, take it out, dry it under nitrogen protection for 50 minutes, and then continue to react at 70°C for 65 minutes under nitrogen protection, the lacrimal duct after r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com