Method for producing trehalose

A production method, the technology of trehalose, is applied in the field of converting maltose into trehalose by using genetically engineered bacteria, which can solve the problems of difficult extraction, difficult mass production of trehalose synthase, difficult immobilization and repeated utilization, etc., and achieves the goal of reducing production costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0011] Example 1 Pichia pastoris displays trehalose synthase from Streptomyces coelicolor

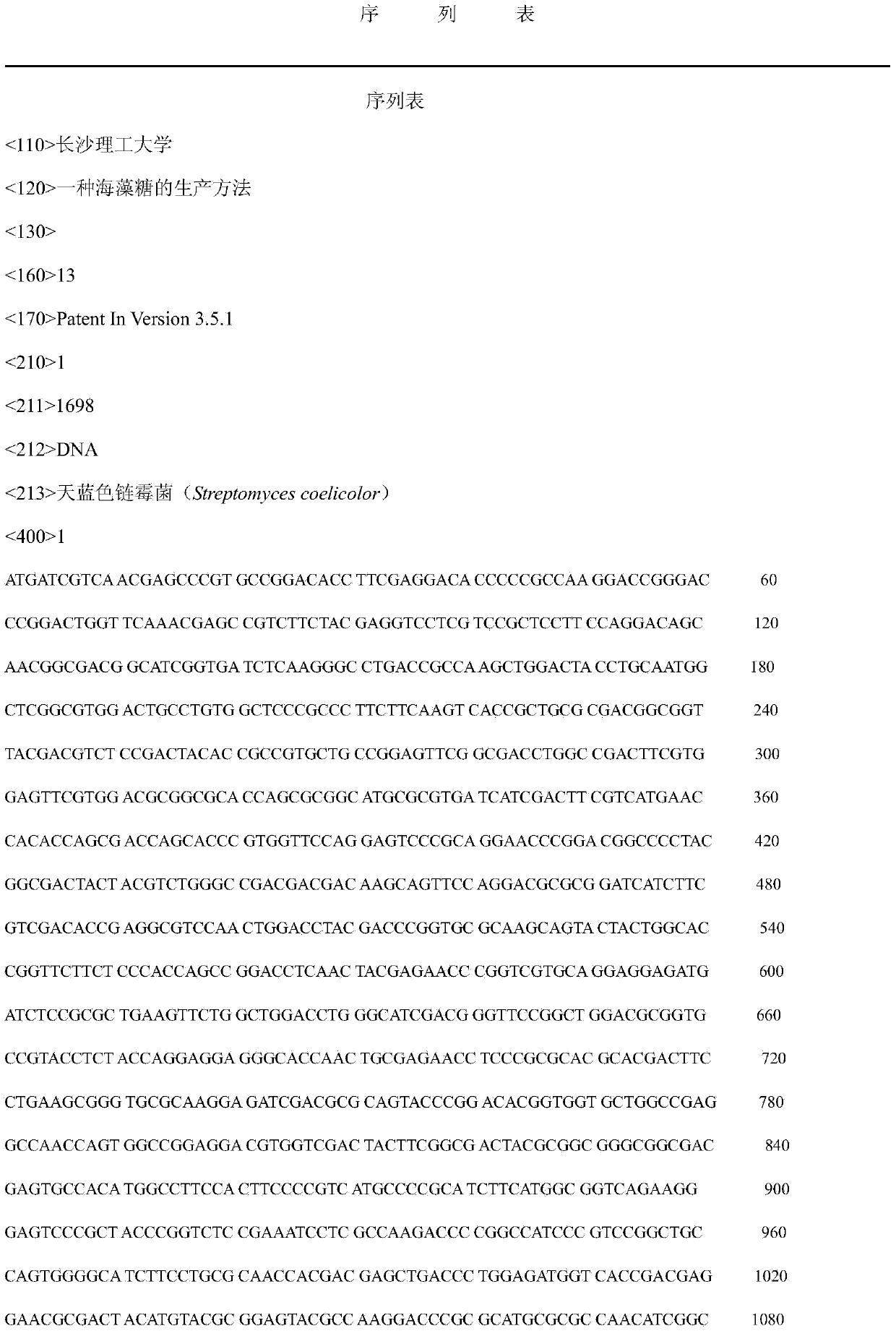

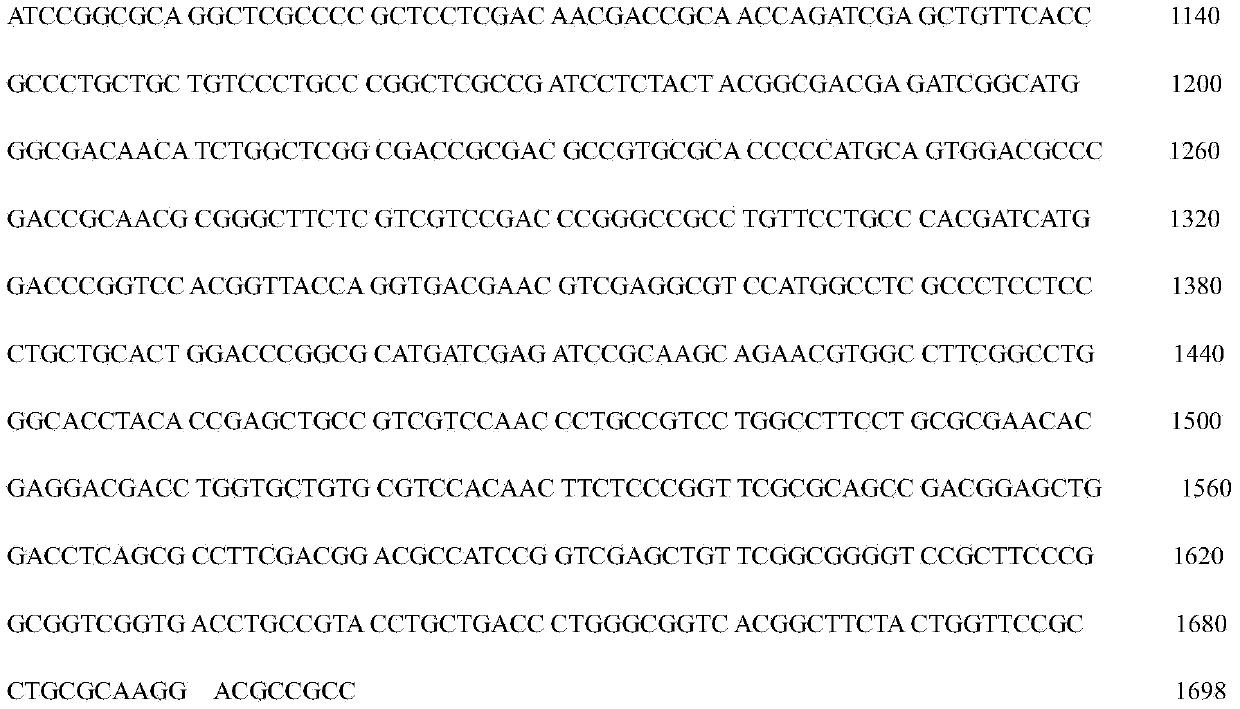

[0012] 1. The synthesis of the trehalose synthase gene (Trehalose synthase, TS) of Streptomyces coelicolor was entrusted to a biological company (in this case, Nanjing GenScript Biotechnology Co., Ltd.), and the gene was cloned on the pUC57 vector (pUC57-TS), and the DNA sequence As shown in SEQ NO1.

[0013] 2. TS subcloning into pPIC9K vector

[0014] The pUC57-TS and pPIC9K vectors were digested with Eco RI and Not I respectively, and the enzyme digestion reaction systems were as follows:

[0015] pUC57-TS plasmid 34ul

[0016] 10* buffer 4 ul

[0017] Eco RI 1 ul

[0018] Not I 1 ul

[0019] A total of 40ul system,

[0020] pPIC9K plasmid 6ul

[0021] 10* buffer 2 ul

[0022] Eco RI 1 ul

[0023] Not I 1 ul

[0024] wxya 2 O 10 ul

[0025] A total of 20 ul system,

[0026] After mixing, they were placed in a water bath at 37°C for 4 h.

[0027] 3. Recover the target ge...

Embodiment 2

[0065] Example 2 Amplification and cultivation of genetically engineered bacteria

[0066] 1. Pick a single colony from the plate, inoculate it in YPD medium, and culture overnight at 30°C and 250 rpm;

[0067] 2. Transfer 1% of the inoculum to fresh BMGY medium, culture at 30°C, 250 rpm for 5 days, add methanol every 24 hours to induce, collect the fermented bacteria, wash 3 times with pH8.0 buffer, and wash with A small amount of buffer solution is resuspended to obtain the recombinant trehalose synthase genetically engineered bacteria liquid, which is centrifuged for dehydration or freeze-dried for later use.

[0068]

Embodiment 3

[0069] Example 3 Production of Trehalose Using Maltose Syrup

[0070] Use pure maltose, pH7.0 disodium hydrogen phosphate and sodium dihydrogen phosphate buffer to make a reaction substrate containing 30% maltose, pH7.0, take 1 liter of prepared reaction substrate and put it into stainless steel In the reaction tank, the temperature is controlled at about 30°C, and the genetically engineered bacterial agent exhibiting trehalose synthase in Example 2 is added according to the weight of 6% sugar solution (about 0.03 liters in volume), and reacted for 4 hours, and then used The HPLC analysis of the various sugar content of the reaction product showed that trehalose was 23.2%, maltose was 4.9%, and glucose was 1.4%. According to 1 liter of 30% maltose + 0.03 liter of enzyme solution, the estimated substrate concentration was 29.1%, and the total conversion rate It is 23.2 / 29.1=79.7%, that is, the content of trehalose in the product of maltose conversion can reach 80%; after the re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com