Preparation method of polyamine compound-modified magnetic chitosan and application thereof

A chitosan, amine modification technology, applied in the directions of alkali metal compounds, chemical instruments and methods, alkali metal oxides/hydroxides, etc., can solve the problems of small adsorption capacity, long adsorption time, difficult recovery, etc. High, good adsorption effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] The degree of deacetylation of the chitosan used is greater than 90%, purchased from Shanghai Lanji Technology Development Co., Ltd.

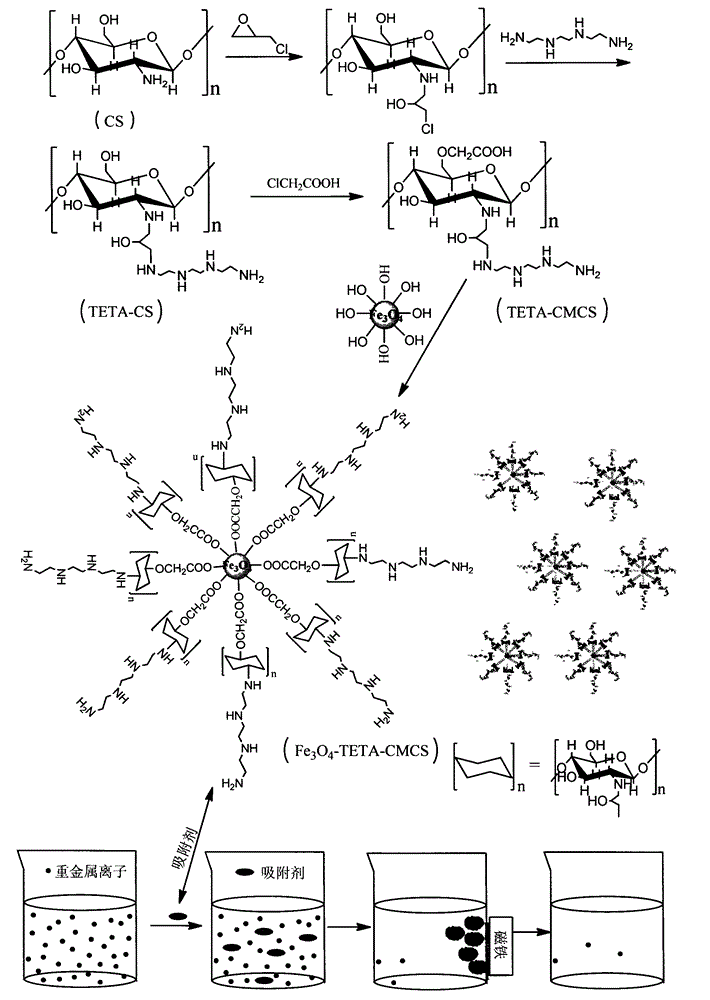

[0024] (1) Preparation of triethylenetetramine modified chitosan

[0025] Dissolve 1g of chitosan (CS) in 100ml of 2% acetic acid solution, add 20ml of dimethyl sulfoxide, and swell for 2 hours; add it to the lye to precipitate while stirring, filter with suction, wash with acetone, and pump until semi-dry. Transfer it into 100ml of acetone, stir to form a suspension, add 5ml of epichlorohydrin dropwise, adjust the temperature to 35°C and react for 24h. Then add 6ml of triethylenetetramine, adjust the temperature to 60°C and react for 6 hours, then add 10ml of triethylenetetramine, 50ml of 1mol / L sodium hydroxide solution, and 0.05g of potassium iodide, continue stirring for 4 hours, cool, filter with suction, and use in turn Wash thoroughly with ionized water, absolute ethanol and acetone, and dry under vacuum at 60°C to obtain a yello...

Embodiment 2

[0033] Step (1), (3) are the same as embodiment 1

[0034] (2) Carboxymethylation of triethylenetetramine modified chitosan

[0035] Take 1.5g of the product in (1) in a three-necked flask, add 20ml of dimethyl sulfoxide and 10ml of 5mol / L sodium hydroxide solution, stir and alkalize at 30°C for 2h; take 5g of chloroacetic acid and dissolve it in 15ml of water, Make it slightly alkaline, add 1g of potassium iodide into the flask, then add 0.1g of hexadecyltrimethylammonium bromide, adjust the temperature to 70°C and react for 5h. Cool to room temperature, wash thoroughly with deionized water, absolute ethanol, and acetone successively, and dry under vacuum at 60°C to obtain a yellow product (TETA-CMCS).

[0036] Invention effect

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com