A high-strength and degradable fracture binding belt and its preparation method

A high-strength, strapping technology, applied in the field of medical devices, can solve the problems of low tensile strength and tensile modulus, slow recovery of bone tissue, stress shielding, etc., to improve strength and modulus, meet high-strength requirements, The effect of excellent strength and modulus

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

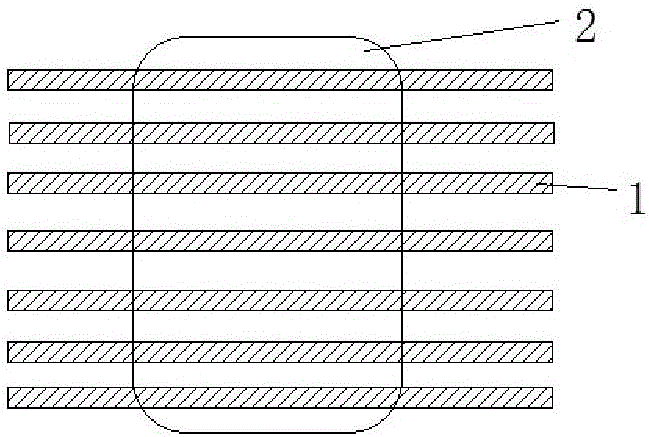

[0044] (1) Accurately weigh 12g of poly-L-lactic acid (PLLA) with a number average molecular weight of 200,000 and 0.5g of citric acid, dissolve in 87.5g of hexafluoroisopropanol, and use an electrospinning machine for electrospinning. A high-oriented fiber tape with a thickness of 0.5um, a width of 2mm, and a fiber diameter of 1 to 2um (such as figure 1 or figure 2 Shown in the highly oriented fiber tape 1), and then placed in a vacuum drying oven for 24 hours, the mechanical performance test results are shown in Table 1, and the degradation performance results are shown in Table 2;

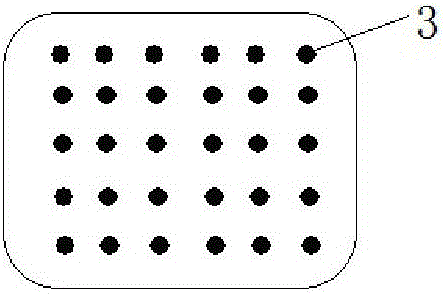

[0045] (2) Arrange the above-mentioned oriented fiber tapes evenly on the surface of the flat-plate yarn collector of the electrospinning machine, dissolve PLLA with a number average molecular weight of 100,000 in hexafluoroisopropanol to prepare a spinning solution with a concentration of 5 wt%, Spinning on the surface of the flat-plate spinner fixed with the oriented fiber tape, the thicknes...

Embodiment 2

[0048] (1) Accurately weigh 5 g of D-polylactic acid (PDLA) with a number-average molecular weight of 300,000 and 1 g of sodium citrate, dissolve them in dichloromethane, and then conduct electrospinning with a dish-shaped yarn take-up at an online speed of A highly oriented fiber tape with a thickness of 10um, a width of 5mm, and a fiber diameter of 0.1-1.0um was prepared under the condition of 700m / min, and then placed in a vacuum drying oven for 24 hours. The mechanical performance test results are shown in Table 1. The degradation performance results Put table 2;

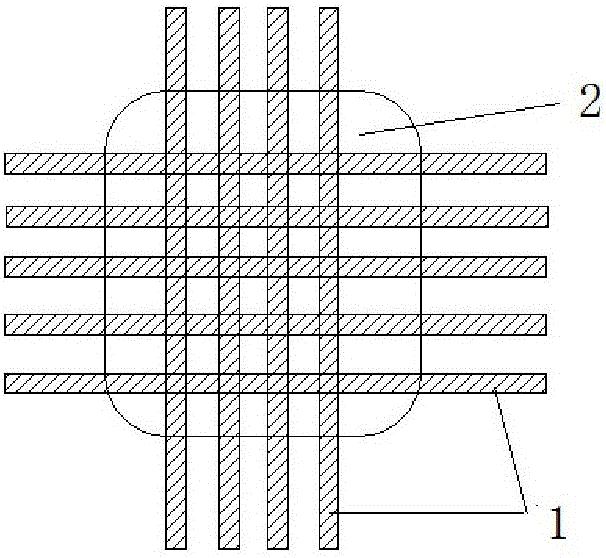

[0049] (2) Arrange the above-mentioned PDLA fiber strips evenly on the surface of the flat winder of the electrospinning machine horizontally and vertically, and dissolve PDLA with a number average molecular weight of 100,000 in dichloromethane to prepare a spinning fiber with a concentration of 8wt%. The silk solution is sprayed on the surface of the flat-plate yarn collector fixed with the oriented fiber tape,...

Embodiment 3

[0052] (1) Accurately weigh 8g of PGA with a number-average molecular weight of 200,000 and 1.5g of sodium citrate, dissolve them in 90.5g of tetrahydrofuran, and then perform electrospinning, using a dish-shaped yarn collector with an online speed of 850m / min Prepare a highly oriented fiber tape with a thickness of 25um, a width of 10mm, and a fiber diameter of 0.1-1.0um under the same conditions, and then put it in a vacuum drying oven for 24 hours. The mechanical performance test results are shown in Table 1, and the degradation performance results are shown in Table 2;

[0053] (2) Arrange the above-mentioned oriented fiber tapes evenly in the horizontal and vertical direction on the surface of the flat winder of the electrospinning machine, and dissolve PGA with a number average molecular weight of 50,000 in tetrahydrofuran to prepare a spinning solution with a concentration of 5wt%. , using an electrospinning machine to spray on the surface of the flat-plate spinner, when...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com