Thermal vanishing ink

An ink and water-soluble technology, applied in the field of ink, can solve the problems of non-heat dissipation, unfavorable ink storage, easy damage to water quality and environment, etc., and achieve the effect of not easy to delaminate, conducive to storage and use, and uniform and stable solution system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 , a thermal dissipation ink

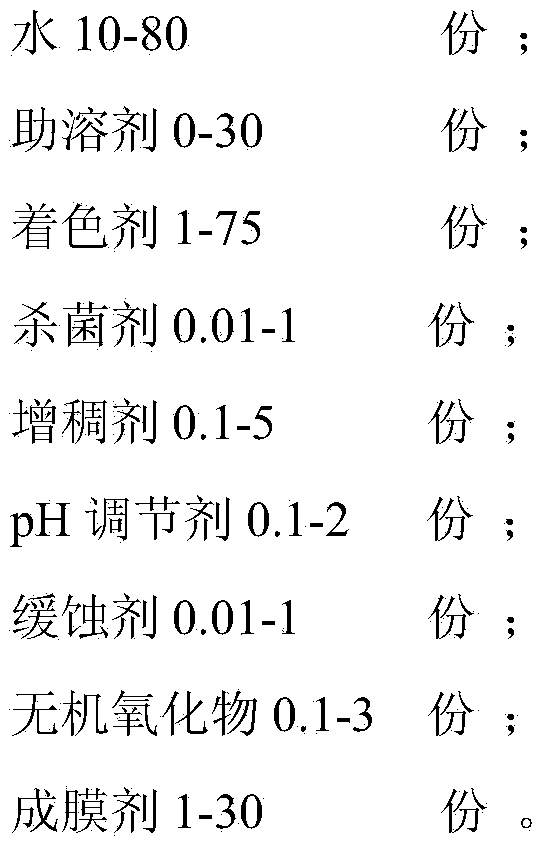

[0026] A kind of thermal erasing ink, is made up of each component of following parts by weight:

[0027]

[0028] in:

[0029] The water is distilled water with a conductivity of 0.1μS / cm;

[0030] Co-solvents contain water-soluble polyols (ethylene glycol);

[0031] The colorant contains leuco dye, surfactant, fatty alcohol, bactericide and color developer. The colorant is microcapsule or crystal of organic synthesis. Liquid, emulsify and disperse the leuco dye, fatty alcohol, and chromogenic agent through a surfactant, and add a bactericide at the same time; wherein, the leuco dye is a spiropyran dye, the surfactant is sucrose ester, and the fatty alcohol is 1 - Octacosanol, the fungicide is pentachlorophenol, and the color developer is bisphenol A;

[0032] The thickener is methyl cellulose;

[0033] The pH regulator is sodium hydroxide;

[0034]The corrosion inhibitor is benzotriazole;

[0035] The inorganic oxide ...

Embodiment 2

[0037] Example 2 , a thermal dissipation ink

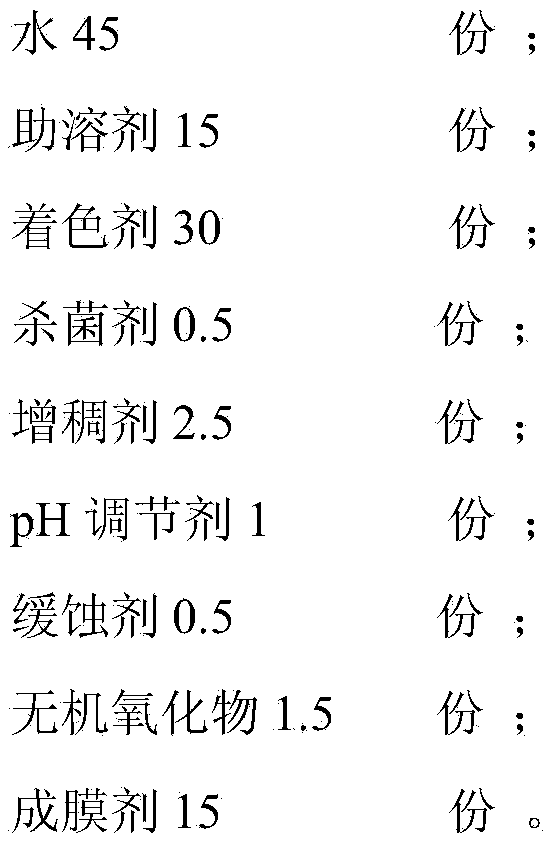

[0038] A kind of thermal erasing ink, is made up of each component of following parts by weight:

[0039]

[0040]

[0041] The water is deionized water with a conductivity of 0.2μS / cm;

[0042] The co-solvent contains water-soluble polyol (diethylene glycol);

[0043] The colorant contains leuco dyes, surfactants, fatty acids, bactericides and color developers. The colorants are microcapsules or organically synthesized crystals. The microcapsules or crystals are pre-prepared color paste concentrates during the production of heat-eliminating inks. , emulsify and disperse the leuco dye, fatty acid, and color developer through a surfactant, and add a bactericide at the same time; wherein, the leuco dye is a quinone dye, the surfactant is sorbitan ester, and the fatty acid is n-decanoic acid. The bactericide is sodium pentachlorophenolate, and the color developer is bisphenol A;

[0044] Thickener is hydroxyethyl cellulose...

Embodiment 3

[0049] Example 3 , a thermal dissipation ink

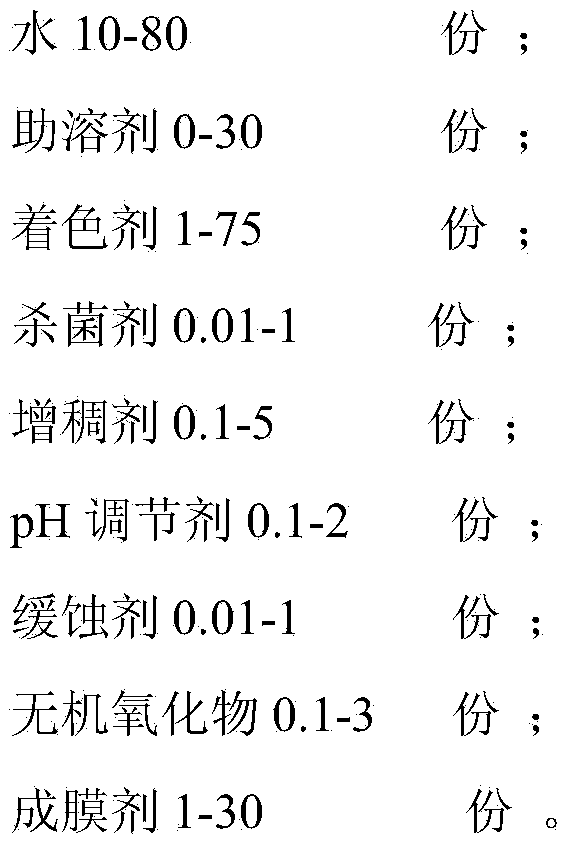

[0050] A kind of thermal erasing ink, is made up of each component of following parts by weight:

[0051]

[0052] The water is distilled water with a conductivity of 0.3μS / cm;

[0053] The co-solvent contains a water-soluble polyol (trimethylolpropane);

[0054] The colorant contains leuco dyes, surfactants, fatty acids, bactericides and color developers. The colorants are microcapsules or organically synthesized crystals. The microcapsules or crystals are pre-prepared color paste concentrates during the production of heat-eliminating inks. , emulsify and disperse the leuco dye, fatty acid, and color developer through a surfactant, and add a bactericide at the same time; wherein, the leuco dye is a thienazine dye, the surfactant is an alkyl alcohol amide, and the fatty acid is lauric acid. The agent is 2-(4-thiazolyl)benzimidazole, and the color developer is bisphenol A;

[0055] The thickener is polyacrylamide;

[0056]...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

| Conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com