Method for producing ethanol through fermentation of starch bearing material via composite fungistat raw material

A starchy raw material and raw meal fermentation technology, applied in fermentation, biofuels, etc., can solve the problem of large amount of penicillin, and achieve the effects of high ethanol concentration, reduced viscosity, and low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

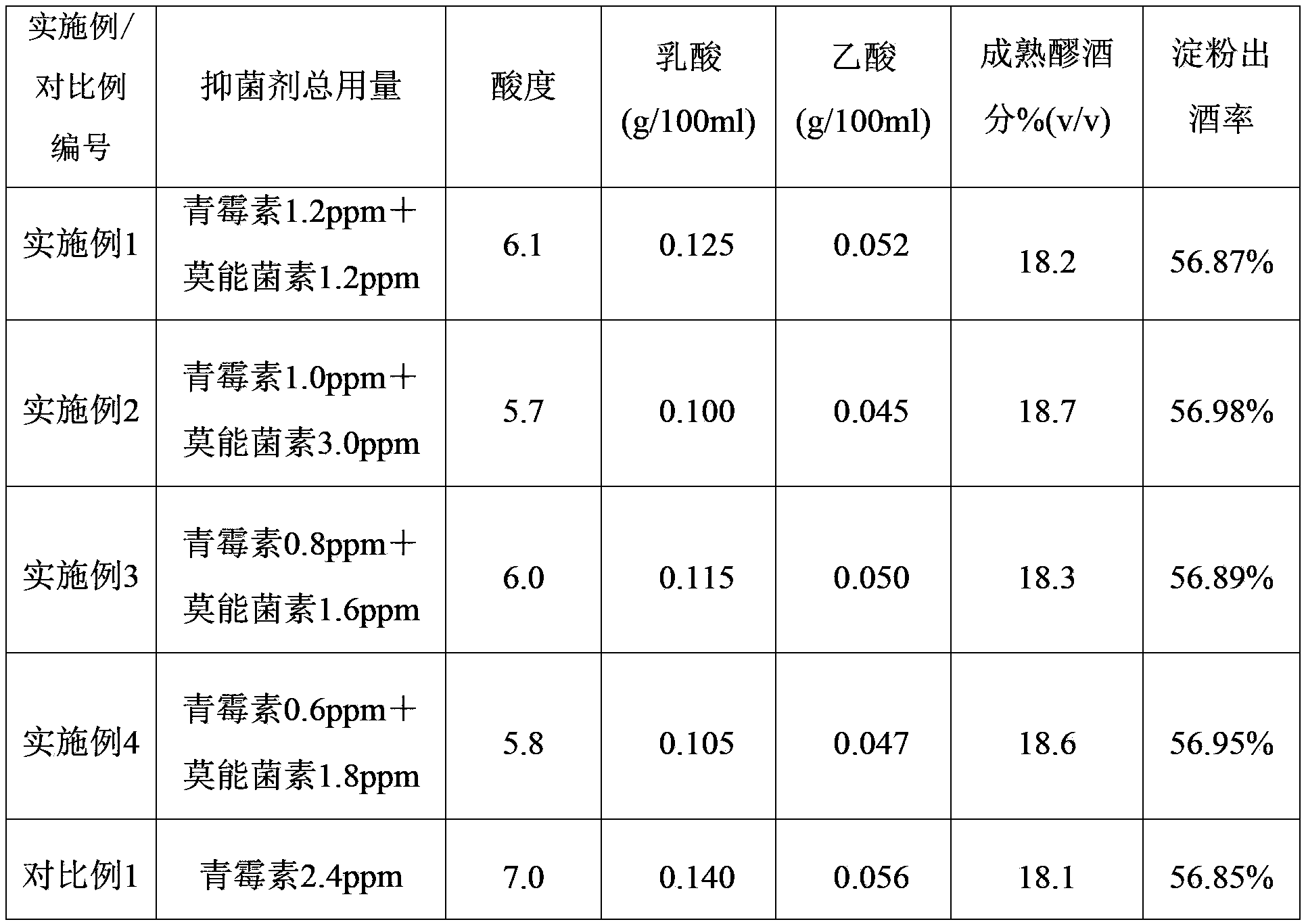

Embodiment 1

[0045] Grind the corn raw material into powder, and the particle size of the crushed corn is 100% and pass through a 30-mesh sieve; it is mixed with water and clear liquid to make a powder slurry with a dry matter concentration of 30%; The weight ratio is 40%); then add penicillin (making the mass concentration in the system 1.2ppm) and monensin (making the mass concentration in the system 1.2ppm), acid protease 17U / g dry basis , amylase 34U / g dry basis, adjust the pH to 4.0, and stir at 63°C for 45min to make pretreated mash; then cool it down to 32.5°C, add magnesium sulfate (to make the mass concentration in the system 1-2ppm), zinc sulfate (making the mass concentration in the system 1-2ppm), urea (making the mass concentration in the system 240-260ppm), ammonium dihydrogen phosphate (making the mass concentration in the system The mass concentration is 10-14ppm), yeast (accounting for 0.2% by weight of the system), glucoamylase 450U / g dry basis, and fermentation for 80h. ...

Embodiment 2

[0047] The corn raw material is ground into powder, and the particle size of the ground corn is 100% and passed through a 35-mesh sieve; it is mixed with water and clear liquid to make a powder slurry with a dry matter concentration of 32%, and the clear liquid is returned to the mixing ratio (to make it in the system The weight ratio is 30%); then add penicillin (making the mass concentration in the system 0.8ppm), monensin (making the mass concentration in the system 1.6ppm), acid protease 15U / g dry basis , amylase 30U / g dry basis, adjust the pH to 4.3, and stir at 60°C for 30min to make pretreated mash; then cool it down to 30°C, add magnesium sulfate (to make the mass concentration in the system 2-3ppm), zinc sulfate (make the mass concentration in the system 2-3ppm), urea (make the mass concentration in the system 265-285ppm), ammonium dihydrogen phosphate (make it in the system The mass concentration is 14-18ppm), yeast (accounting for 0.4% by weight of the system), gluc...

Embodiment 3

[0049] The corn raw material is ground into powder, and the particle size of the ground corn is 100% and passed through a 40-mesh sieve; it is mixed with water and clear liquid to make a powder slurry with a dry matter concentration of 33%, and the clear liquid is returned to the mixing ratio (to make it in the system The weight ratio is 20%); then add penicillin (making the mass concentration in the system 0.6ppm), monensin (making the mass concentration in the system 1.8ppm), acid protease 20u / g dry basis , amylase 40u / g dry basis, adjust the pH to 4.5, and stir at 65°C for 60min to make pretreated mash; then cool it down to 35°C, add magnesium sulfate (to make the mass concentration in the system 2.5-3.5ppm), zinc sulfate (make the mass concentration in the system 2.5-3.5ppm), urea (make the mass concentration in the system 270-300ppm), ammonium dihydrogen phosphate (make it in the system The mass concentration in the mixture is 16-20ppm), yeast (accounting for 0.3% by weig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com