High-temperature semiconductor solid crystal solder paste and preparation method thereof

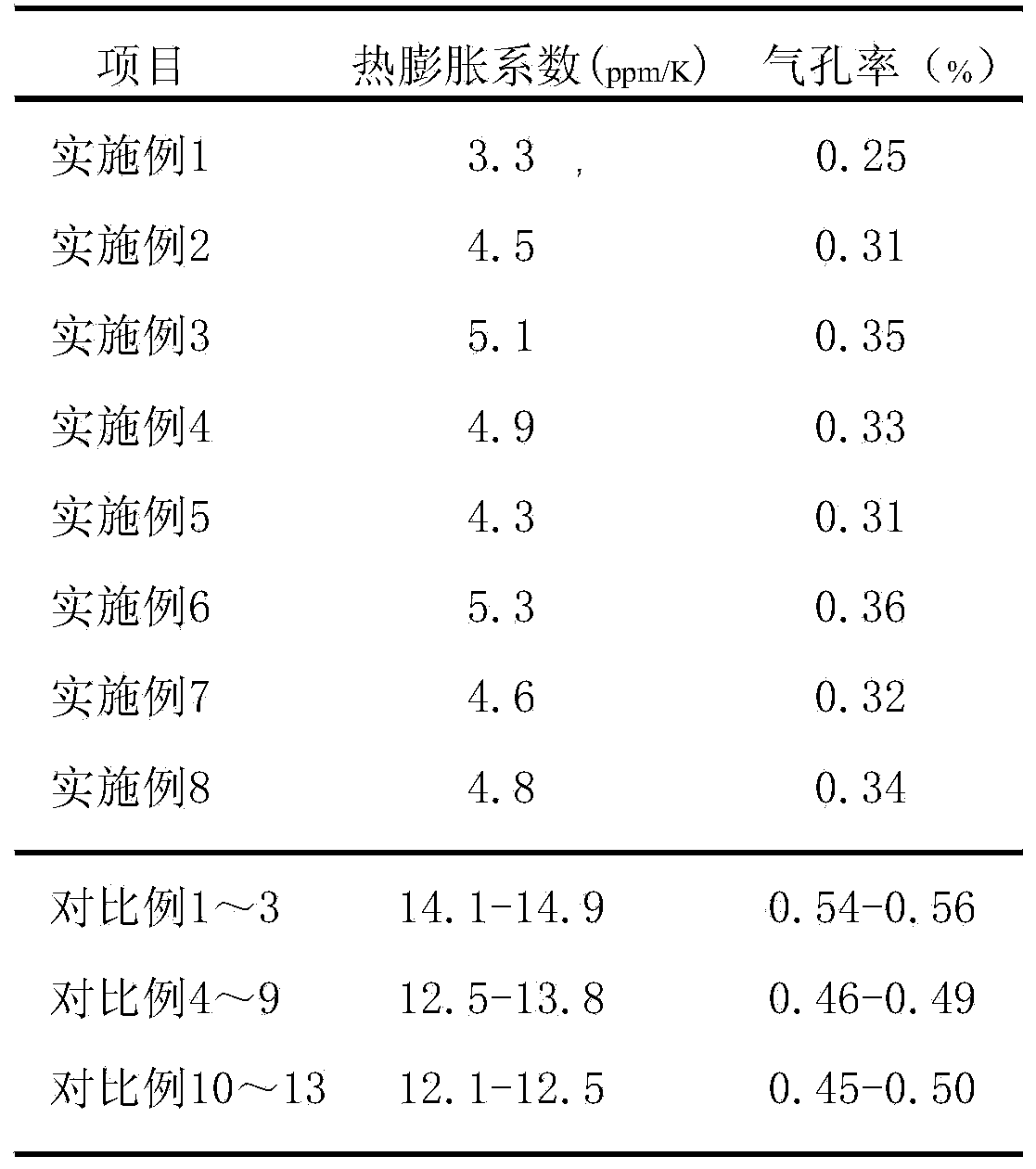

A semiconductor and die-bonding technology, applied in welding equipment, welding media, manufacturing tools, etc., can solve the problems of high thermal expansion coefficient, low welding strength, poor wettability, etc., achieve good wettability, low porosity, meet The effect of multiple reflows

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] This embodiment relates to the preparation of a high-temperature semiconductor die-bonding solder paste, comprising the following steps:

[0030] Step (1), preparation of solder paste

[0031] Take the following components by weight percentage: 35% polymerized rosin resin, 6% malonic acid, 4.5% hydrogenated castor oil, 1.5% methylamine, 3.5% pentaerythritol 2-hexyldecanoate, 1.5% antioxidant BHT, Organosilane coupling agent KH-5502%, the rest of diethylene glycol octyl ether, then mix the above components evenly, heat until completely dissolved, then cool naturally to room temperature, and then refrigerate the composition at 5°C get solder paste;

[0032] Step (2), preparation of solder paste

[0033] Select the PbInAg spherical metal alloy powder whose weight percentage is Pb:In:Ag=92.5:5:2.5, the particle size is 29 μm, and the spherical rate is 98%, according to the weight percentage of PbInAg spherical metal alloy powder and solder paste 87:13 , put the two in a ...

Embodiment 2

[0035] This embodiment relates to the preparation of a high-temperature semiconductor die-bonding solder paste, comprising the following steps:

[0036] Step (1), preparation of solder paste

[0037] Weigh the following components by weight percentage: 30% hydrogenated rosin resin, 5% succinic acid, 5% ethylene bis stearamide, 1% trimethylamine, 3.5% decyl myristate, 2% antioxidant DLTP, organic Silane coupling agent KH-5601%, the balance of diethylene glycol hexyl ether, and then mix the above components evenly, heat until completely dissolved, then naturally cool to room temperature, and then refrigerate the composition at 2°C to prepare solder paste;

[0038] Step (2), preparation of solder paste

[0039] Select the PbInAg spherical metal alloy powder whose weight percentage is Pb:In:Ag=92.5:5:2.5, the particle size is 25 μm, and the spherical rate is 99%, according to the weight percentage of PbInAg spherical metal alloy powder and solder paste 82:18 , put the two in a ...

Embodiment 3

[0041] This embodiment relates to the preparation of a high-temperature semiconductor die-bonding solder paste, comprising the following steps:

[0042] Step (1), preparation of solder paste

[0043] Weigh the following components by weight percentage: petroleum modified resin 32%, adipic acid 6%, polyamide resin 4%, aniline 1.5%, rosin alcohol ether surfactant 4%, antioxidant 10101%, organosilane Joint agent KH-5702%, the rest of 2-ethyl-1,3-hexanediol, and then mix the above components evenly, heat until completely dissolved and then cool to room temperature naturally, then put the composition at 3°C Refrigerate to prepare solder paste;

[0044] Step (2), preparation of solder paste

[0045] Select the PbInAg spherical metal alloy powder whose weight percentage is Pb:In:Ag=92.5:5:2.5, the particle size is 35 μm, and the spherical rate is 95%, according to the weight percentage of PbInAg spherical metal alloy powder and solder paste 91:9 , put the two in a disperser and stir...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap