Method for recovering ethanol in analginum production

Analgin and ethanol technology, applied in the field of pervaporation membrane applications, can solve the problems of easy introduction of the third component into the product, large amount of the third component, and large equipment footprint, so as to improve energy utilization and save Reagent consumption and the effect of less equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

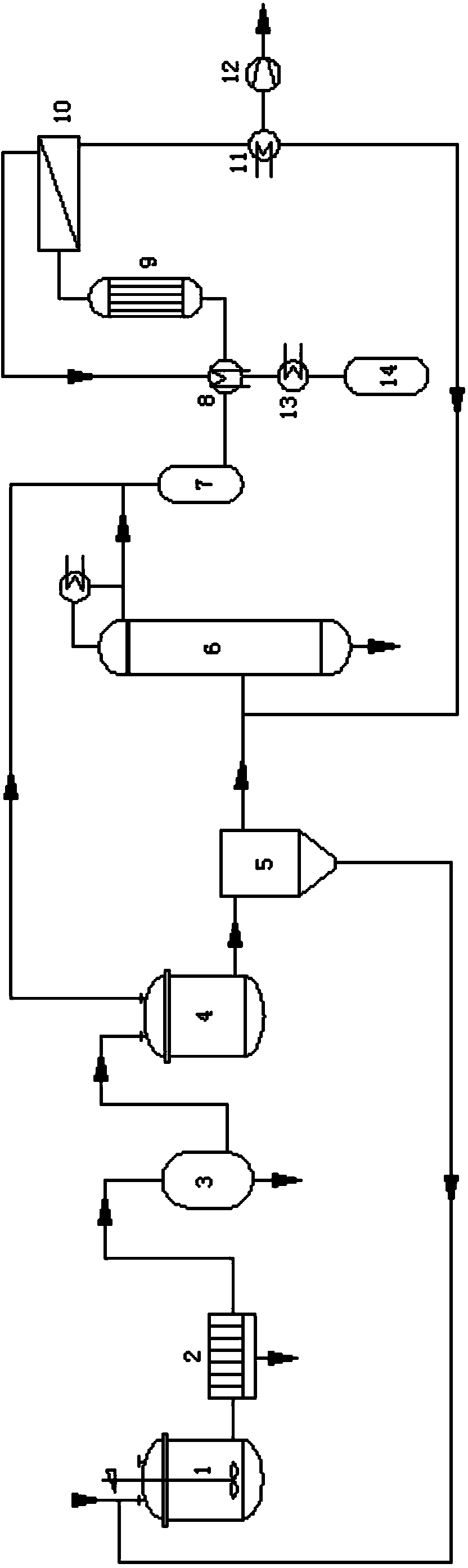

Image

Examples

Embodiment 1

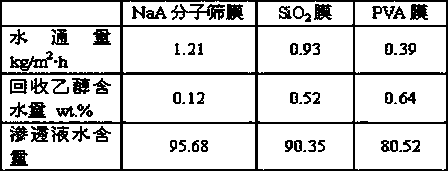

[0044] When using different membrane materials, the obtained data such as recovered ethanol, permeate, and flux are shown in Table 1.

[0045] Table 1

[0046]

[0047] It can be seen from the table that the molecular sieve membrane is particularly suitable for the dehydration treatment of recovered ethanol, and the obtained treatment capacity and permeation flux are better than other types of membrane materials, and the water content of the permeate is also better than other several membrane materials.

[0048]

[0049] Example 2

Embodiment 2

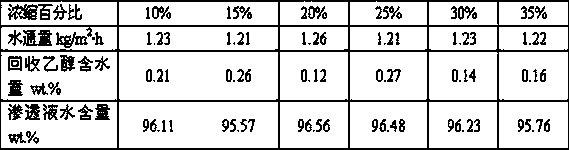

[0051] When using different concentration percentages, the obtained data such as recovered ethanol, permeate, and flux are shown in Table 2.

[0052] Table 2

[0053]

[0054] It can be seen from the table that when the concentration ratio of the still is controlled in an appropriate range, the impurities in the mother liquor can be effectively entered into the steam, and the water flux and the purity of recovered ethanol can be improved.

[0055]

[0056] Example 3

Embodiment 3

[0058]

[0059] Example 4

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com