Nano-hydroxyapatite/sodium alginate composite material, preparation method and application of nano-hydroxyapatite/sodium alginate composite material

A nano-hydroxyapatite, hydroxyapatite technology, applied in chemical instruments and methods, alkali metal compounds, other chemical processes, etc., can solve the problems of high cost, unsuitable removal of heavy metal ions, secondary pollution, etc. Inexpensive, optimized heavy metal removal, good biocompatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

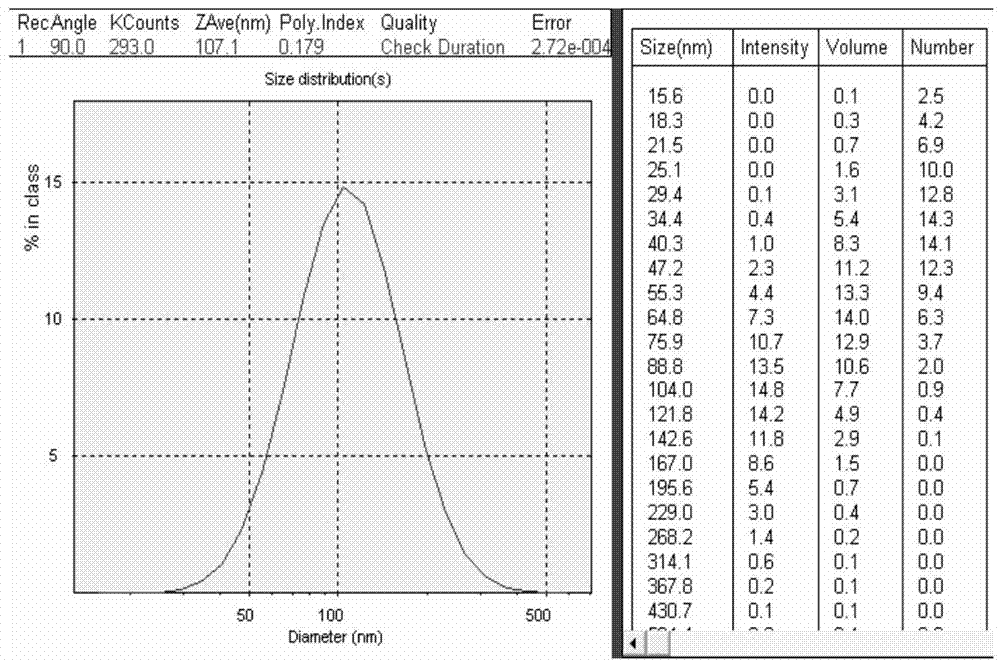

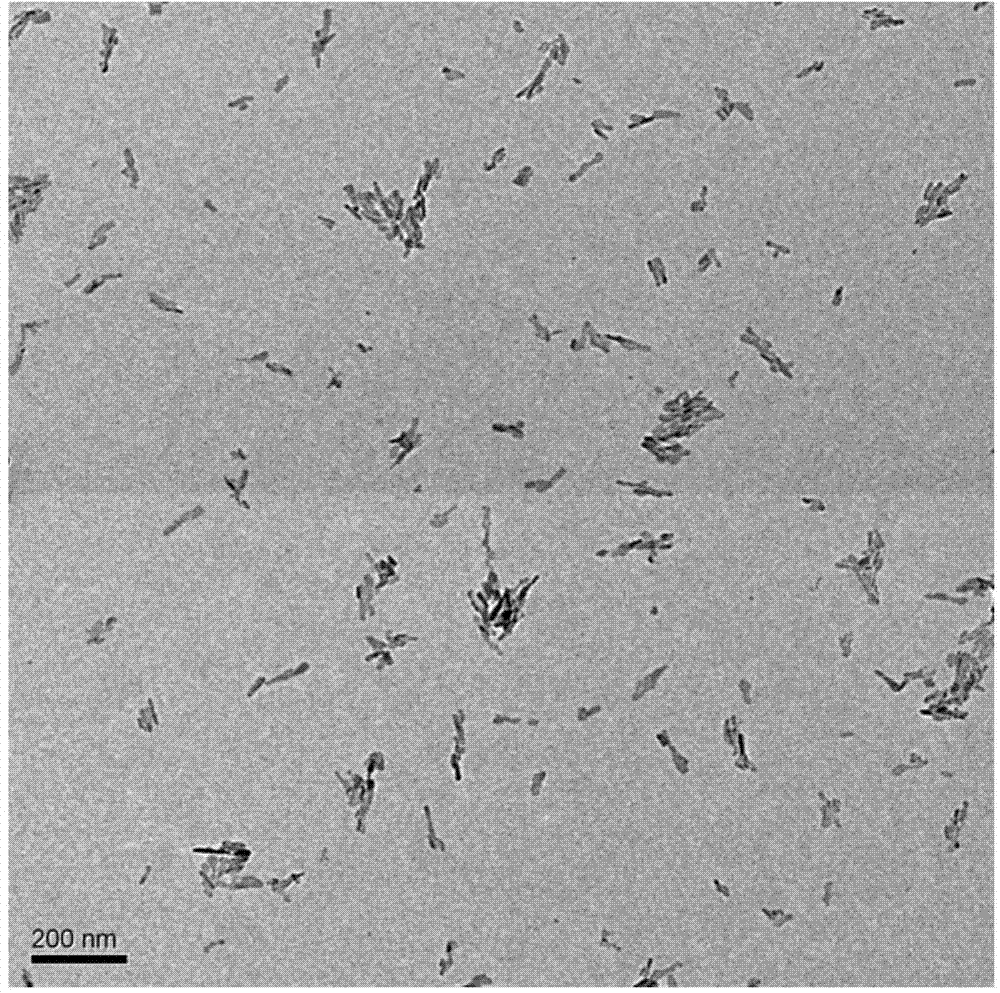

[0026] First, prepare an aqueous solution of calcium nitrate, Ca 2+ Concentration is 0.0334mol / L; prepare diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.02mol / L; according to the molar ratio Ca / P = 1.67, quickly pour 100mL diammonium hydrogen phosphate aqueous solution into 100mL calcium nitrate aqueous solution at 80°C, stir and mix evenly, and centrifuge to obtain the precipitate after reacting for 1 hour. Rinse 3 times with deionized water and redisperse in 200mL deionized water. Then, polyacrylic acid was added (the concentration after being added to the solution was 0.3mg / mL), and the high-energy ultrasonic probe was ultrasonically dispersed for 4 minutes to obtain a stable suspension. The average particle size of hydroxyapatite nanoparticles measured by the laser particle size analyzer was 107.1 nm( figure 1 ), the transmission electron microscope showed short columnar nanoparticles of 15-20nm×100-200nm ( figure 2 ). Add 0.607 g of s...

Embodiment 2

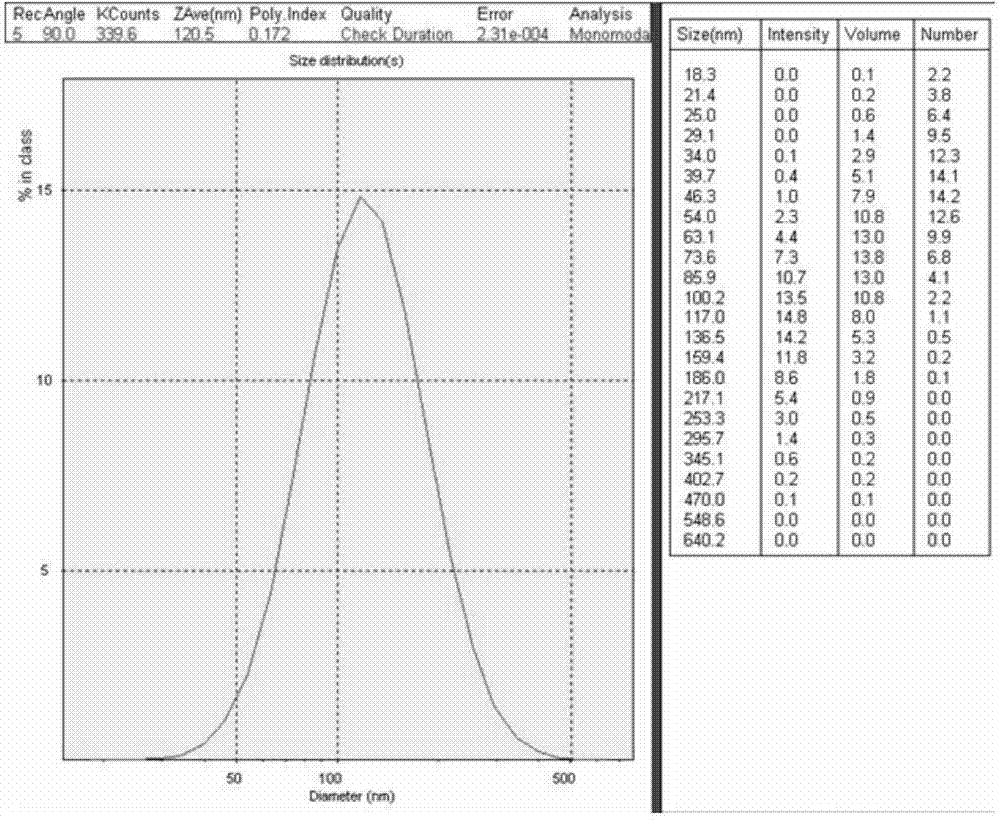

[0028] First, prepare an aqueous solution of calcium nitrate, Ca 2+ The concentration is 0.0668mol / L; prepare diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.04mol / L. According to the molar ratio Ca / P=1.67, quickly pour 100mL diammonium hydrogen phosphate aqueous solution into 100mL calcium nitrate aqueous solution at 80°C, stir and mix evenly, after reacting for 1 hour, centrifuge to obtain the precipitate, rinse it with deionized water for 3 times Redisperse in 200 mL deionized water. Then, polyacrylic acid was added (the concentration after being added to the solution was 0.5mg / mL), and the high-energy ultrasonic probe was ultrasonically dispersed for 4 minutes to obtain a stable suspension. The average particle size of hydroxyapatite nanoparticles measured by the laser particle size analyzer was 120.5 nm( image 3 ), the transmission electron microscope showed short columnar nanoparticles of 10-15nm×80-100nm ( Figure 4 ). Finally, add ...

Embodiment 3

[0030] First, prepare an aqueous solution of calcium nitrate, Ca 2+ The concentration is 0.1002mol / L; prepare diammonium hydrogen phosphate aqueous solution, PO 4 3- The concentration is 0.06mol / L. According to the molar ratio Ca / P=1.67, quickly pour 100mL diammonium hydrogen phosphate aqueous solution into 100mL calcium nitrate aqueous solution at 80°C, stir and mix evenly, after reacting for 1 hour, centrifuge to obtain the precipitate, rinse it with deionized water for 3 times Redisperse in 200 mL deionized water. Then, polyacrylic acid was added (the concentration after adding into the solution was 0.7 mg / mL), and the high-energy ultrasonic probe was ultrasonically dispersed for 6 minutes to obtain a stable suspension. Finally, add 0.1821 g of sodium alginate to the suspension (36.2 mL) containing 0.1821 g of hydroxyapatite, stir at 80 ° C, and as the water evaporates, the volume is reduced to 1 / 9, and a viscous colloidal state is obtained. things. After lyophilizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com