A kind of preparation method of epoxy modified aliphatic polythiourethane

A polythiourethane and epoxy modification technology, applied in the field of polyurethane composite materials, can solve the problems of poor adhesion and chemical resistance, achieve excellent elasticity and compactness, excellent toughness and wear resistance, and improve The effect of overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] The specific preparation operation steps of epoxy modified aliphatic polythiourethane elastomer are as follows:

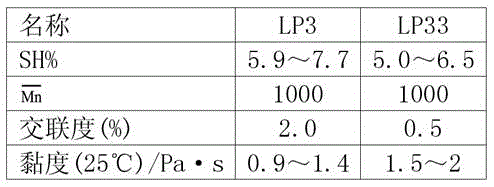

[0033] 1) Preparation of hydroxyl-terminated polysulfide-modified aliphatic polyurethane prepolymer

[0034] Under the protection of dry nitrogen, vacuum dehydrated liquid polysulfide LP3 (Mn=1000): 7 grams, polytetrahydrofuran ether diol (Mn=2000): 50 grams, isophorone diisocyanate (IPDI): 3.5 gram of the mixture was added to the reactor at one time, and the temperature was controlled at 70°C for 3 hours to the end under mechanical stirring, and the system was cooled to 30°C to obtain a terminally active hydrogen prepolymer;

[0035] 2) Preparation of isocyanate-terminated epoxy resin modified aliphatic polyurethane adduct

[0036] Epoxy H 12 E-44: Add 2.4 grams of ethylenediamine dropwise to 7.1 grams of ethylenediamine at 30°C within 20 minutes, keep the reaction at 30°C for 0.5 hours, raise the reactant to 65°C, add it dropwise to 26.2 grams of IPDI wi...

Embodiment 2

[0046] Under the protection of dry nitrogen, vacuum dehydrated liquid polysulfide LP3 (Mn=1000): 6.4 grams, polyhexamethylene adipate diol (Mn=2000): 45 grams, isophorone diisocyanate ( IPDI): 3.1 g of the mixture was added to the reactor at one time, and the temperature was controlled at 70°C under mechanical stirring to react to the end; a terminal active hydrogen prepolymer was obtained.

[0047] Cool the system down to 40°C, put the epoxy resin H 12 E-44: Add 2.15 grams of ethylenediamine dropwise to 6.4 grams of ethylenediamine at 30°C within 20 minutes, keep the reaction at 30°C for 0.5 hours, add the reactant dropwise to 23.3 grams of IPDI at 65°C within 30 minutes, and keep it for 1 hour. This results in an isocyanate-terminated adduct.

[0048] Add 31.9 grams of adducts to 54.5 grams of prepolymer, add dropwise 0.1 grams of stannous octoate and 0.3 grams of dibutyltin dilaurate, react at 70 ° C to the end, reduce the system temperature to 35 ° C, and obtain epoxy mod...

Embodiment 3

[0052] Under the protection of dry nitrogen, vacuum dehydrated liquid polysulfide LP3 (Mn=1000): 7 grams, polycarbonate 1,6-hexanediol (Mn=2000): 50 grams, isophorone di Isocyanate (IPDI): 3.6 grams of the mixture was added to the reactor at one time, and the temperature was controlled at 70°C under mechanical stirring to react to the end; an active hydrogen-terminated prepolymer was obtained.

[0053] Cool the system down to 40°C, put the epoxy resin H 12 E-44: Add 2.3 grams of ethylenediamine dropwise to 7.0 grams of ethylenediamine at 30°C within 20 minutes, keep the reaction at 30°C for 0.5 hours, add the reactant dropwise to 26.0 grams of IPDI at 65°C within 30 minutes, keep it for 1 hour, and get Isocyanate-terminated adducts.

[0054] Add 35.3 grams of adducts to 60.6 grams of prepolymer, add 0.01 grams of stannous octoate and 0.3 grams of dibutyltin dilaurate dropwise, react at 70°C to the end, lower the system temperature to 35°C, and obtain epoxy modified aliphatic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com