Ionic liquid-polymer composite membrane for hydrogen chloride fuel cell and preparation and application thereof

A hydrogen chloride fuel cell and ionic liquid technology, applied in fuel cells, solid electrolyte fuel cells, circuits, etc., can solve the problems of no new type of electrolyte membrane research, material corrosion, etc., and achieve easy control of doping amount and high conductivity , low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

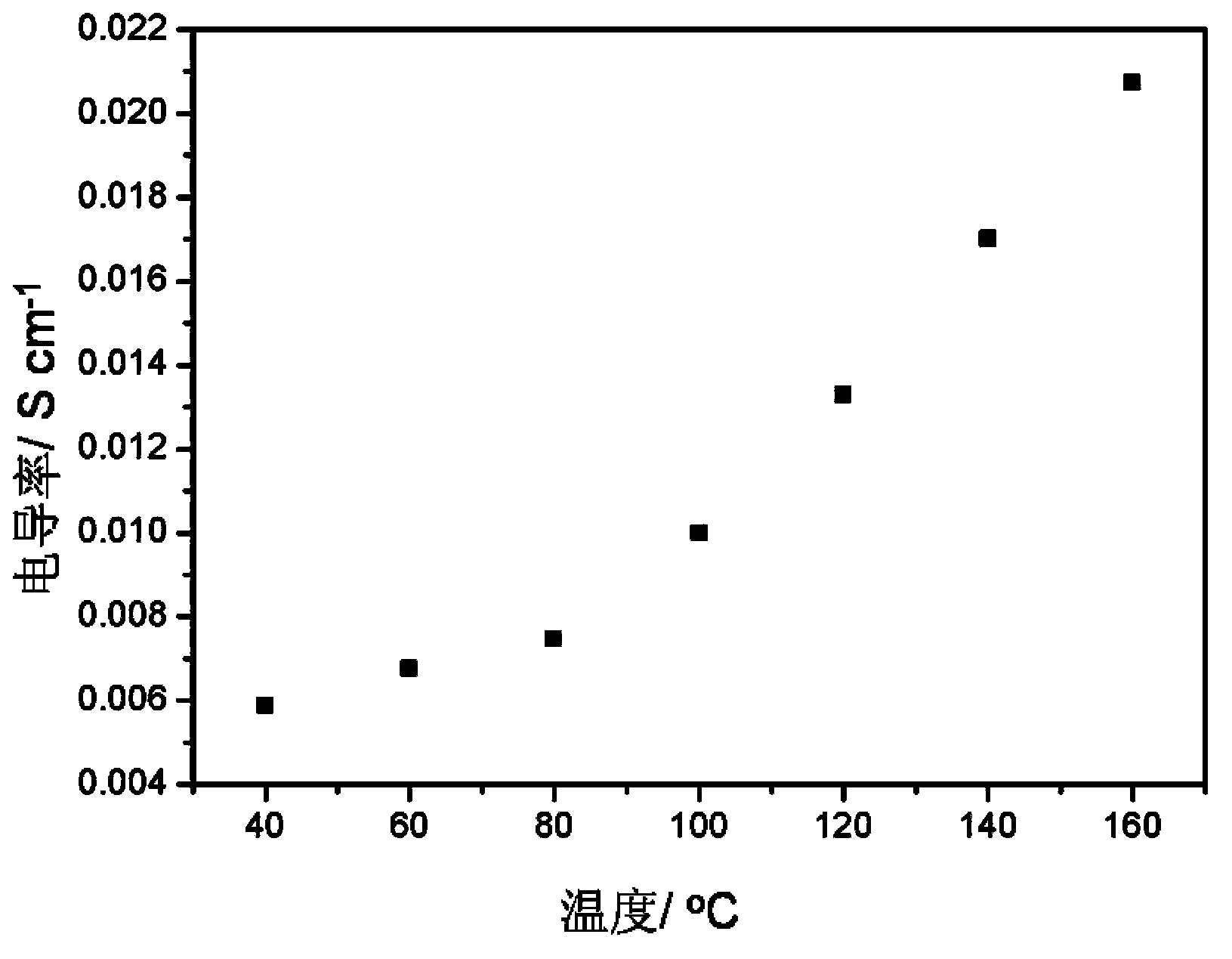

[0026] Embodiment 1: 0.25g high-purity polybenzimidazole (PBI, molecular weight M w =58000), mixed with 30g of analytically pure DMF, stirred magnetically at room temperature for 5h, filtered through filter paper, added 1.25g of diethylmethylamine trifluoromethanesulfonate ([dema]TfO) and ultrasonically mixed for 1h, oil at 80°C Stir in the bath for 5h, stand still at room temperature for 2h to defoam, and form a film in an oven at 80°C. The film thickness was 60 μm. The obtained film has a compact structure (see the attached electron microscope photo of the film section) figure 1 ), using the AC impedance method (EIS) to test its conductivity at different temperatures (no humidification at all, see attached figure 2 ), the breaking strength is 20MPa.

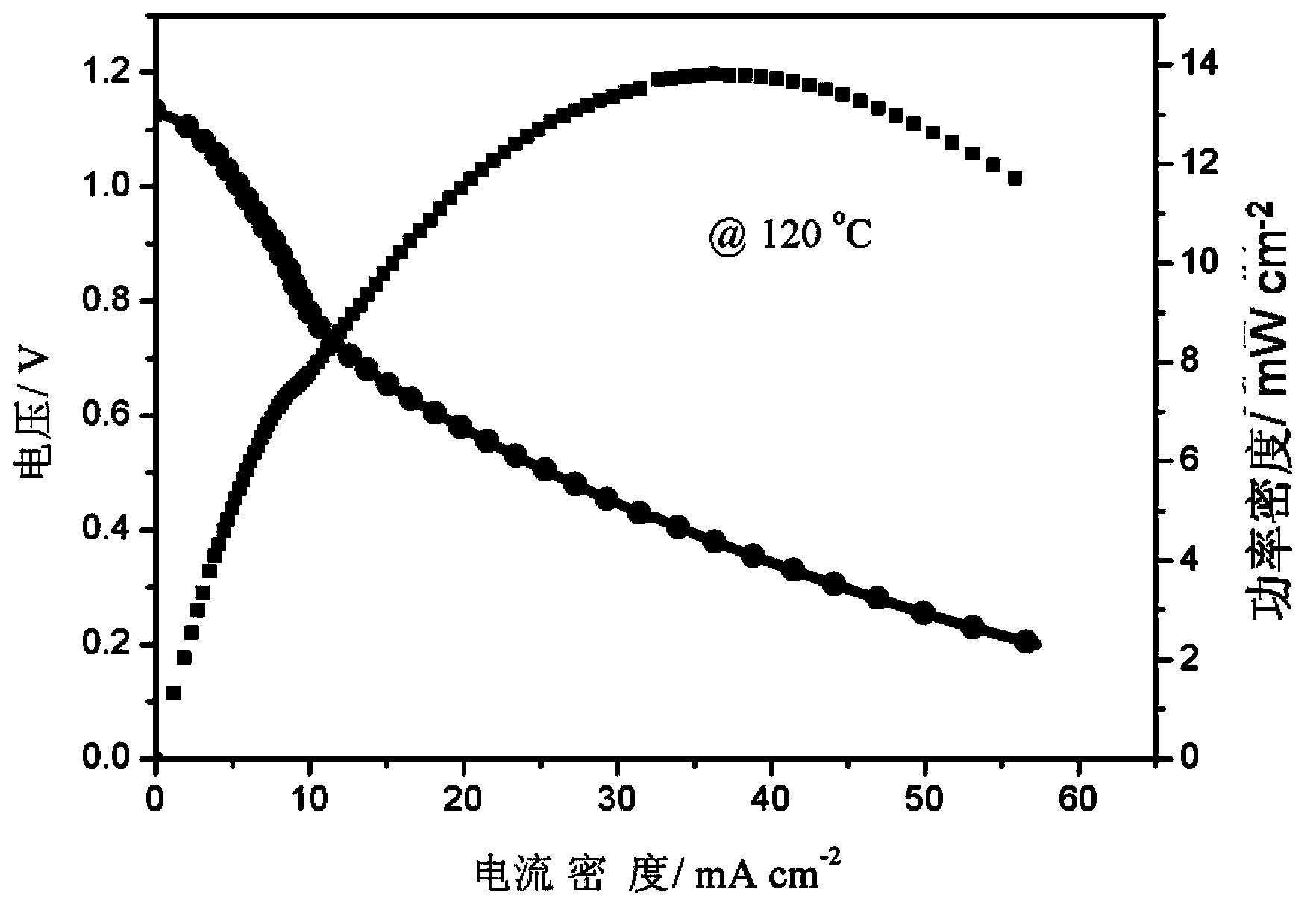

[0027] The electrode is prepared by the method described in the patent CN02127802.4 (the binder is PBI, the catalyst is 70% Pt / C), and the Pt loading of the catalyst in the electrode is 0.4mg cm -2 . In order to ensure th...

Embodiment 2

[0029] Embodiment 2: 0.3g polyethersulfone (PES, M w =60000), 30g NMP mixed, stirred at room temperature for 1h, added 1g1-ethyl-3-methylimidazolium tetrafluoroborate ([EMIm]BF 4 ), ultrasonically mixed for 0.5h, stirred in an oil bath at 90°C for 3h, then stood still for 1h for degassing, and formed a film in an oven at 80°C. The film thickness was 125 μm. The obtained film has a compact structure (see the attached electron microscope photo of the film section) Figure 4 ), using the four-probe method to test its conductivity at different temperatures (no humidification at all, see attached Figure 5 ), the breaking strength is 15MPa.

Embodiment 3

[0030] Example 3: 10g of Nafion solution (DuPont, 5wt.%) and 10g of DMAC were ultrasonically mixed for 3h, and 1g of 1-methyl-3-butylsulfonic acid imidazole hydrogen sulfate ([BMIm]HSO 3 HSO 4 ), stirred at room temperature for 5 hours, then stood still for 3 hours to degas, and cast a film in an oven at 60°C. The film thickness was 100 μm. The obtained film has a compact structure (see the attached electron microscope photo of the film section) Image 6 ), using the four-probe method to test its conductivity at different temperatures (no humidification at all, see attached Figure 7 ), the breaking strength is 30MPa.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| breaking strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com