Preparation method of esterification modified xanthan gum

A technology of esterification modification and xanthan gum, which is applied in the field of polymer chemistry and polymer modification, can solve environmental pollution and other problems, and achieve the effects of simple post-processing, convenient storage and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

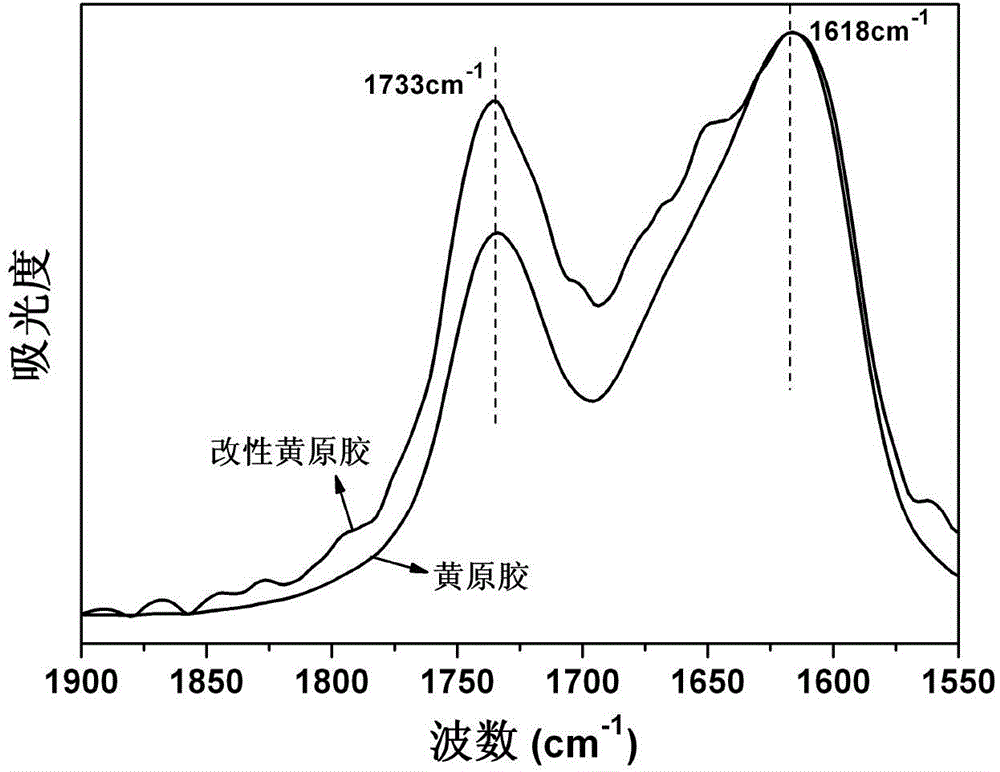

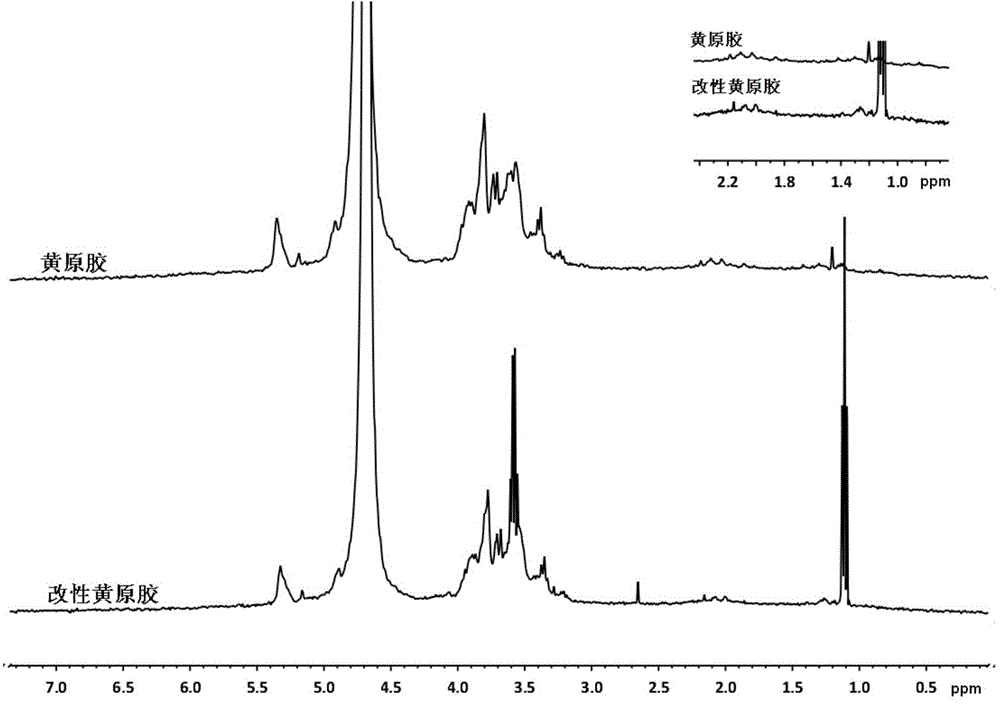

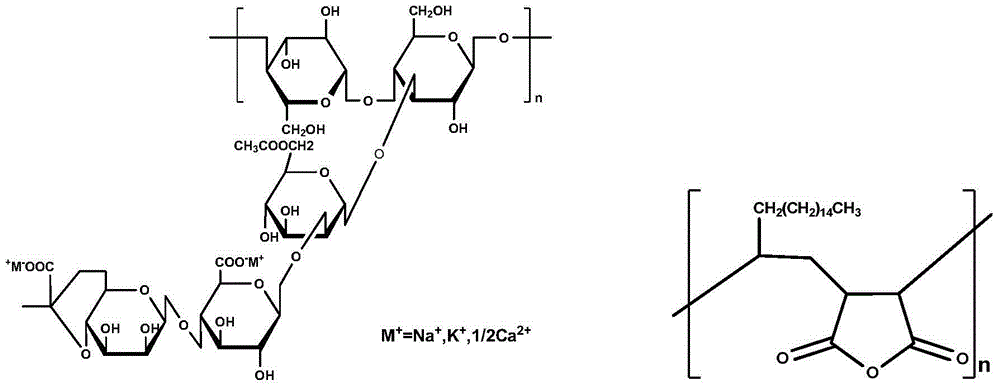

Method used

Image

Examples

Embodiment 1

[0039] 5.6 g of vacuum-dried xanthan gum was added to 120 ml of DMSO, and the mixture was fully stirred and swollen at 40 °C for 12 h. Dissolve 0.4 g of PMAO in 30 ml of chloroform, add dropwise to the reaction system with a constant pressure dropping funnel, heat up to 70 °C, and react for 16 h. After the reaction was completed, it was cooled to room temperature, the reaction solution and the solid product were added to 350 ml of acetone, and the supernatant was discarded after fully stirring. The solid product was washed 4 times with ethanol precipitation, each 400ml. After suction filtration, the product was vacuum-dried at 25°C for 48h to obtain 5.45g of modified xanthan gum. After static light scattering test, its weight average molecular weight is 4.12 million.

[0040]The salt resistance test was carried out on the xanthan gum before modification and the xanthan gum obtained after esterification modification in this example, and the salt used was NaCl. Prepare salt s...

Embodiment 2

[0053] As described in Example 1, the difference is that in step (2), the amount of xanthan gum is changed to 8 g to obtain 7.63 g of modified xanthan gum. The weight-average molecular weight of the modified xanthan gum was measured by static light scattering to be 2.92 million.

Embodiment 3

[0055] As described in Example 1, the difference is that in step (3), the amount of PMAO is changed to 0.1 g to obtain 5.39 g of modified xanthan gum. The weight-average molecular weight of the modified xanthan gum was measured by static light scattering to be 2.63 million.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com