Reforming hydrogen preparing device capable of recycling pressure swing absorption desorption gas and technique thereof

A pressure swing adsorption and reforming hydrogen production technology, which is applied in electrical components, fuel cell additives, fuel cells, etc., can solve the high performance requirements of CO selective oxidation catalysts, the inability to achieve stable chemical reactions, material management and Difficulties in energy management and other issues to achieve environmental friendliness, avoid burning hot spots, and improve energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

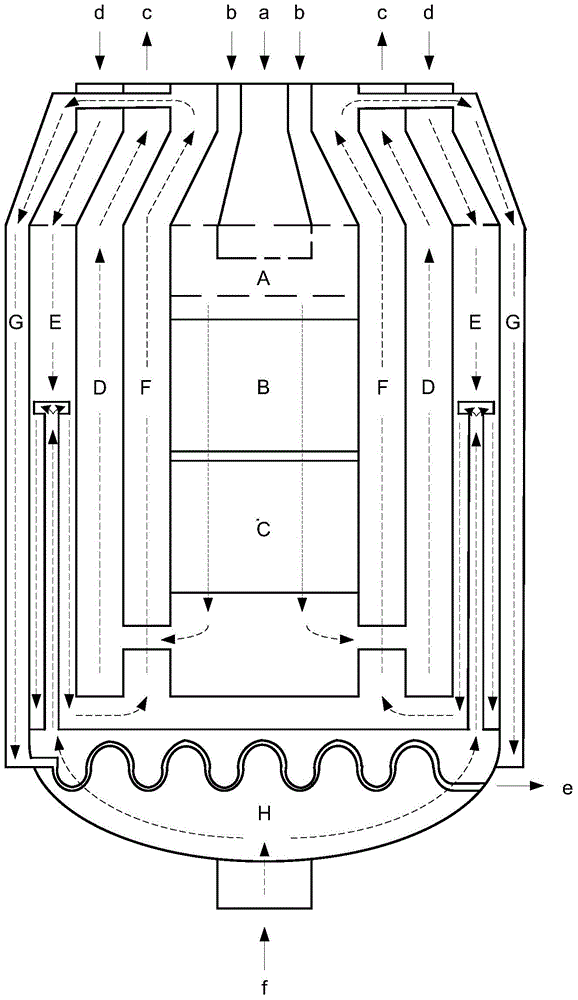

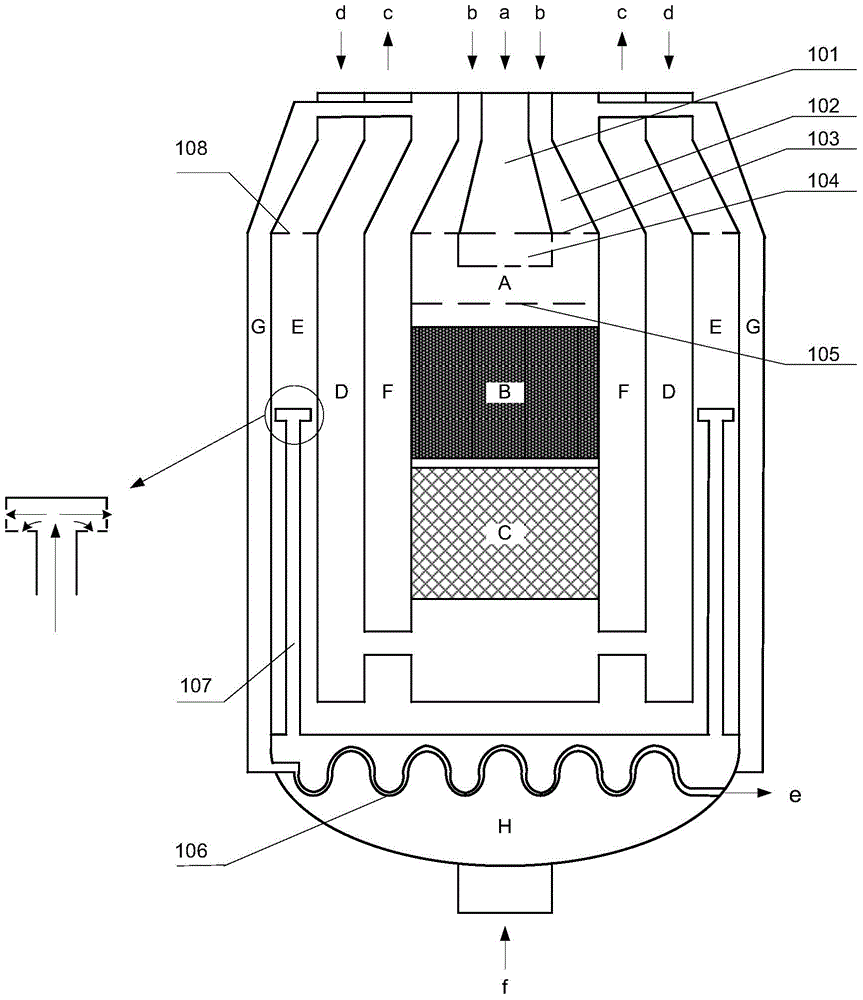

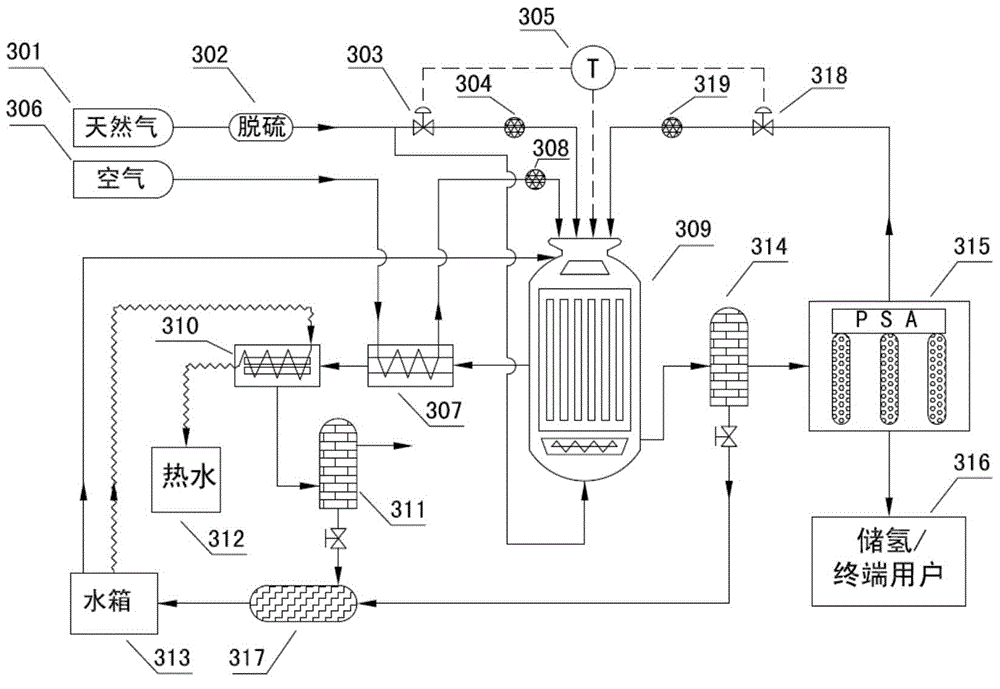

[0030] Natural gas reforming hydrogen production unit ( figure 1 ), mainly including combustible gas mixing buffer zone A, analytical gas recovery conversion zone B, catalytic combustion transition zone C, second reaction zone D for air and combustible gas, reforming raw material mixing zone E, natural gas reforming hydrogen production first zone Area F, the second area G for hydrogen production by reforming natural gas, and reforming feed gas buffer H and other main functional areas. First, a certain amount of pressure swing adsorption analysis gas and air that need to be recovered and processed are fed into the heating inlet a and air inlet b of the natural gas reforming hydrogen production unit respectively. Recycling conversion zone B, catalytic combustion transition zone C, second reaction zone D for air and combustible gas, and combustion tail gas is discharged from the system through combustion tail gas outlet c. The raw material gas required for hydrogen production b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com