Thermal power plant desulphurization wastewater purification system and purification method

A desulfurization wastewater and purification system technology, applied in the direction of chemical instruments and methods, gaseous effluent wastewater treatment, general water supply conservation, etc., can solve the problems of equipment corrosion, low efficiency, complicated process, etc., and achieve reduced processing load and low energy consumption , the effect of preventing membrane fouling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

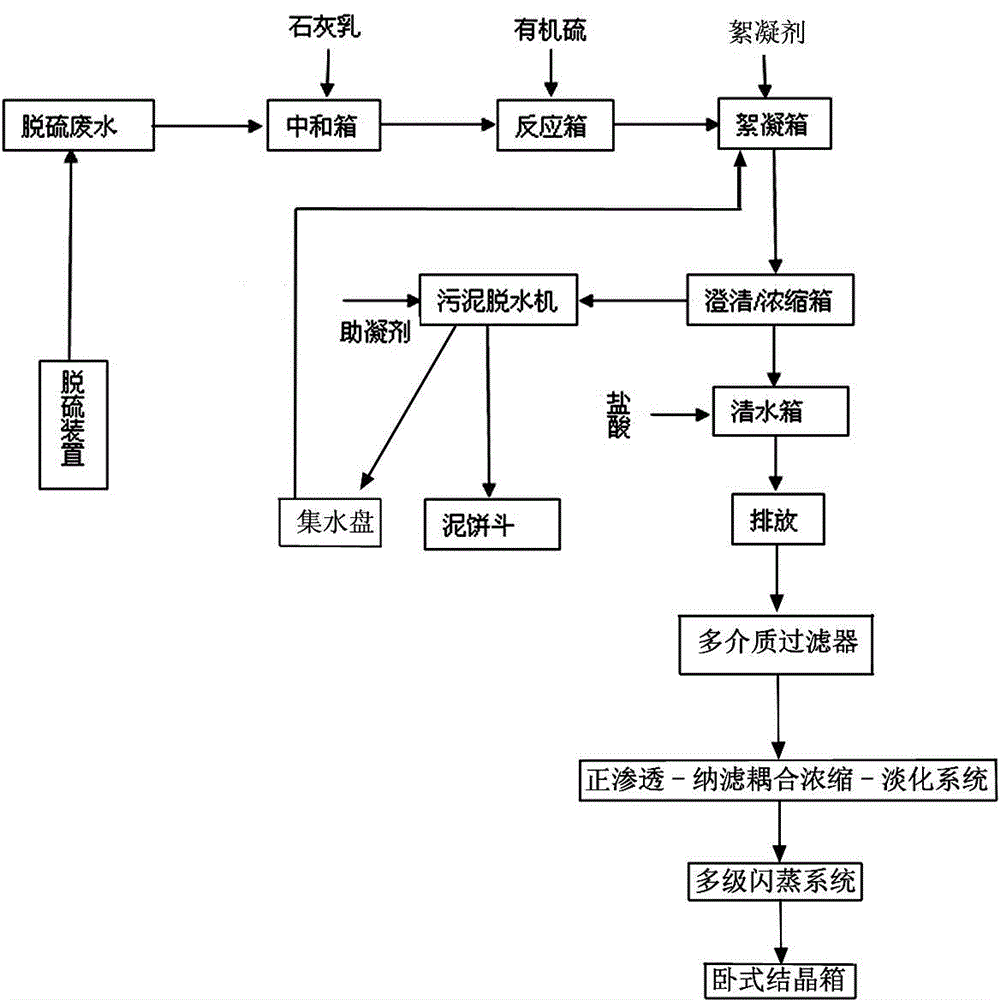

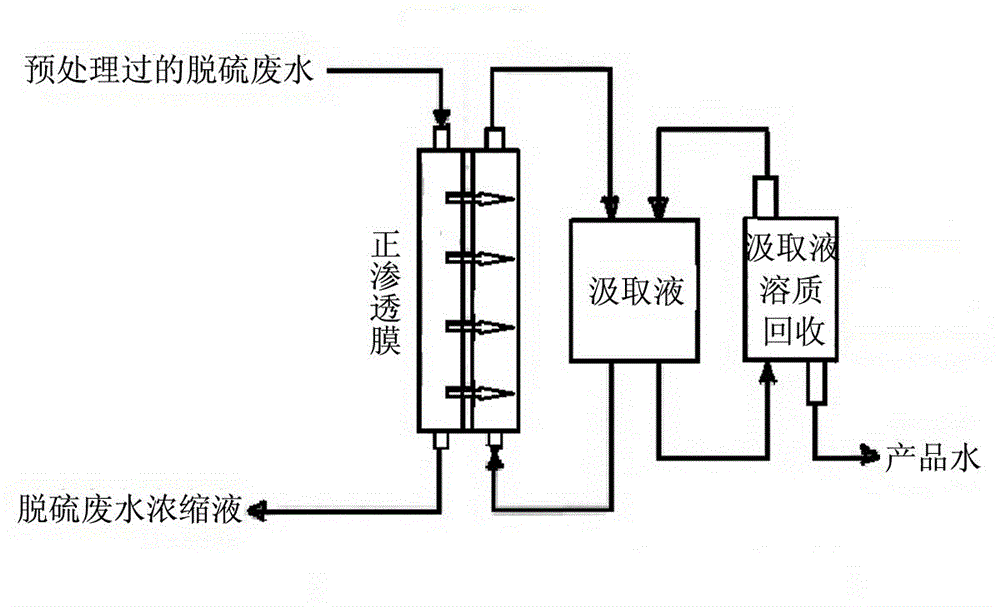

[0040] The present invention will be further described below in conjunction with the accompanying drawings. The following examples are only used to illustrate the technical solution of the present invention more clearly, but not to limit the protection scope of the present invention.

[0041] The desulfurization systems of two 660MW ultra-supercritical units in a power plant share a comprehensive wastewater treatment system with automatic control function, and the treated wastewater volume is about 2×12.5 t / h. Excess indicators in wastewater are mainly suspended solids, pH value, mercury, copper, lead, arsenic, fluorine, calcium, magnesium, aluminum, iron, and chloride, sulfate, sulfite, carbonate, etc.

[0042] During the continuous circulation process, the slurry in the desulfurization system will accumulate harmful components such as chlorine radicals, metal ions and fine particles. Excessive concentration of these harmful components will accelerate the corrosion of desulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com