Diaphragm for lithium-sulfur batteries and preparation method of lithium-sulfur batteries

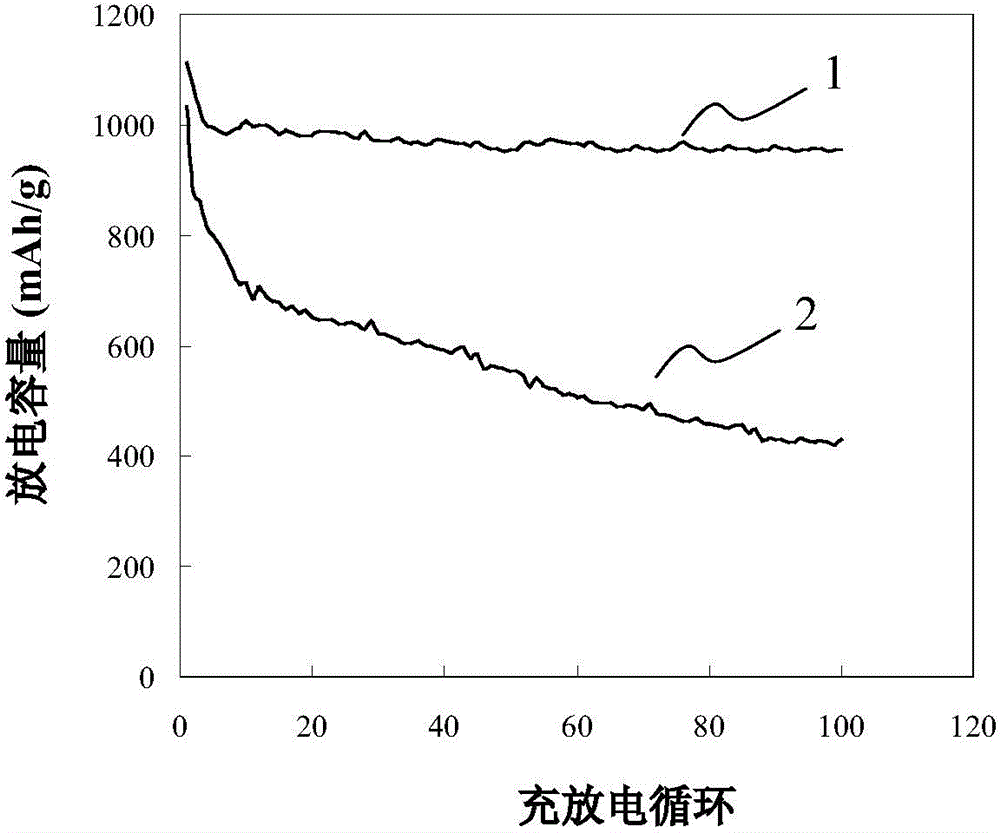

A lithium-sulfur battery and membrane technology, applied in the field of preparation of lithium-sulfur battery membrane and lithium-sulfur battery, can solve the problems of lithium-sulfur battery capacity decline, capacity loss, capacity decline, etc., and achieve good chemical stability and thermal stability , high safety and reliability, and the effect of eliminating the possibility of reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A method for preparing a lithium-sulfur battery separator specifically includes the following steps:

[0036] (1) Take 100mL of N-methylpyrrolidone (NMP) and add 3~10g Li + -After Nafion resin and 3~10g PVP resin are stirred and dissolved, 1g polyolefin fiber is added, and after ultrasonic vibration (ultrasonic frequency 40kHz) is dispersed for 30 minutes, then 0.5~5g nano metal sulfide is added, and ultrasonic vibration (ultrasonic frequency 40kHz) is dispersed 2 After hours, pour it into a membrane maker and heat it to 90°C to slowly evaporate NMP. After heating at 90°C for 20 hours, a metal sulfide-containing polyolefin fiber reinforced lithium ion exchange membrane is obtained;

[0037] Among them, Li + -The preparation method of Nafion resin is: take 100mL Nafion solution (20wt%, produced by DuPont), add 10g LiOH, stir for 30 minutes, centrifuge to separate the excess LiOH to obtain Li + -Nafion solution, Li can be obtained after spray drying + -Nafion resin powder. The...

Embodiment 1

[0047] Example 1 Preparation of Nano Metal Sulfide

[0048] Weigh copper nitrate (0.1 mol) and add it to a reactor containing 100mL deionized water, add a stir bar, stir to dissolve, add 2g PVP and stir to dissolve, weigh sodium sulfide according to the molar ratio of copper nitrate to sodium sulfide 1:1 (0.1 mol) was added to the reactor, stirred and reacted for 30 minutes to obtain nano-copper sulfide, filtered, rinsed with deionized water and dried to obtain nano-copper sulfide powder.

[0049] Substituting equimolar amounts of zinc nitrate and tin nitrate to replace the copper nitrate, and following the above steps to obtain nano zinc sulfide and nano tin sulfide powders, respectively.

Embodiment 2

[0050] Example 2Li + -Nafion powder preparation

[0051] Add 10g LiOH to 100mL of Nafion solution (20wt%). After stirring for 30 minutes, centrifuge to separate the excess LiOH to obtain Li + -Nafion solution, get Li after spray drying + -Nafion resin powder.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com