Composite pure waterborne hard-to-be-adhered material adhesive for packaging paper commodities and preparation method thereof

A pure water-based technology for packaging, applied in the direction of grafted polymer adhesives, adhesives, adhesive types, etc., can solve the problems that the surface tension cannot be reached, disappears, and endangers the health of the staff, and achieves good The effect of the bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

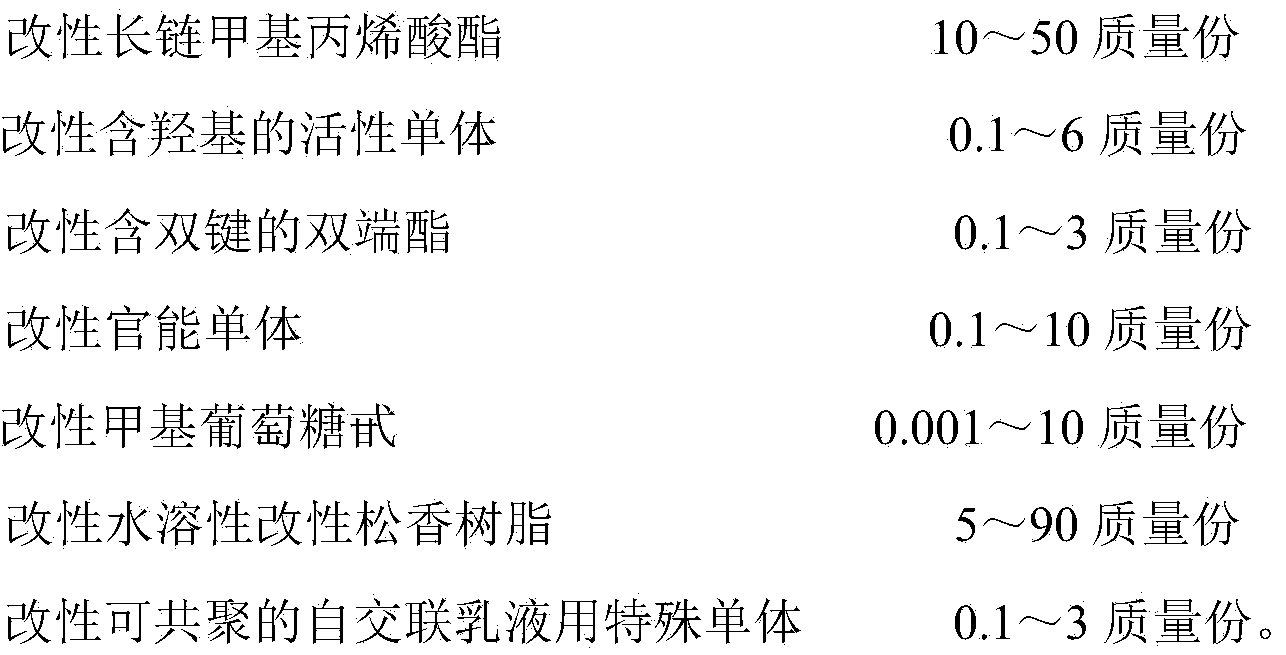

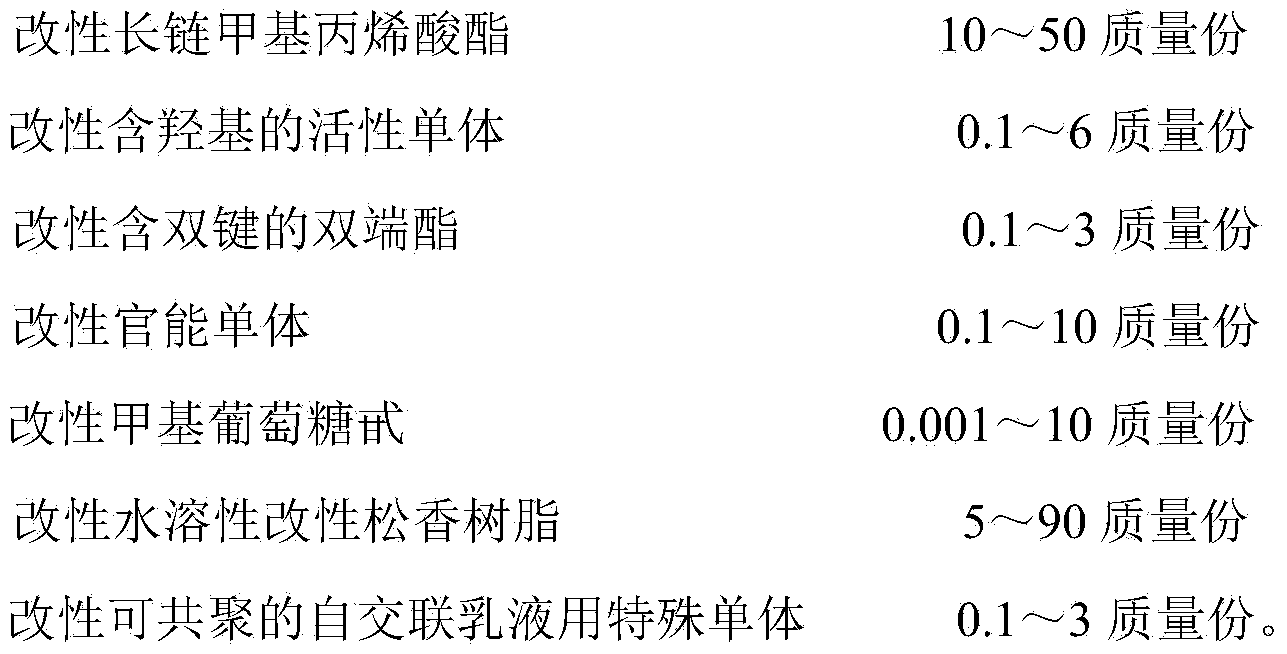

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: long-chain methacrylate is methyl methacrylate, butyl methacrylate, 2-ethylhexyl methacrylate according to methyl methacrylate: butyl methacrylate: 2-methacrylate Ethylhexyl ester = mixed long-chain methacrylate obtained by mixing the mass mixing ratio of 2:3:5; the active monomer containing hydroxyl is selected from pentaerythritol triacrylate; Ether methacrylate; the functional monomer is pentaerythritol tetraacrylate; the water-soluble modified rosin resin is water-soluble fumaric acid modified rosin resin; the special monomer for copolymerizable self-crosslinking emulsion is acetoacetate ethyl methacrylate Diol diester; chain transfer agent is 2,4-diphenyl-4-methyl-1-pentene; reactive emulsifier is allyloxypropyl alkyl alcohol polyether and allyloxynonyl Phenoxypropanol polyoxyethylene ether ammonium sulfate is obtained by mixing allyloxypropyl alkyl alcohol polyether: allyloxynonylphenoxypropanol polyoxyethylene ether ammonium sulfate = 3:2 mass ratio...

Embodiment 2

[0082]Embodiment 2: long-chain methacrylate is methyl methacrylate, butyl methacrylate, 2-ethylhexyl methacrylate according to methyl methacrylate: butyl methacrylate: 2-methacrylate Ethylhexyl ester = 3:4:3 mass mixing ratio mixed long-chain methacrylate; trimethylolpropane diacrylate is selected as active monomer containing hydroxyl; double-end ester containing double bond is Methoxy polyether methacrylate; functional monomer lauryl acrylate; water-soluble modified rosin resin is water-soluble fumaric acid modified rosin resin; special monomer for copolymerizable self-crosslinking emulsion is methyl Ethylene glycol diester acetoacetate; chain transfer agent is 2,4-diphenyl-4-methyl-1-pentene; reactive emulsifier is allyloxypropyl alkyl alcohol polyether and allyl Oxynonylphenol propanol polyoxyethylene (4) ether ammonium sulfate according to allyloxypropyl alkyl alcohol polyether: allyloxynonylphenol propanol polyoxyethylene (4) ether ammonium sulfate = 1: The reactive emul...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com