NOx adsorbent

An adsorbent and grinding technology, applied in other chemical processes, dispersed particle separation, chemical instruments and methods, etc., can solve the problems of complex adsorbent preparation methods, short adsorbent replacement cycle, low adsorption efficiency, etc. Adsorption reaction rate, long replacement cycle, and the effect of improving adsorption efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] This example is an example of low-concentration nitrogen oxide treatment, and the exhaust gas is a laboratory simulation of different concentrations of NO x Emissions, using pure NO from gas cylinders 2 Gas, experimental gas volume 2L / min.

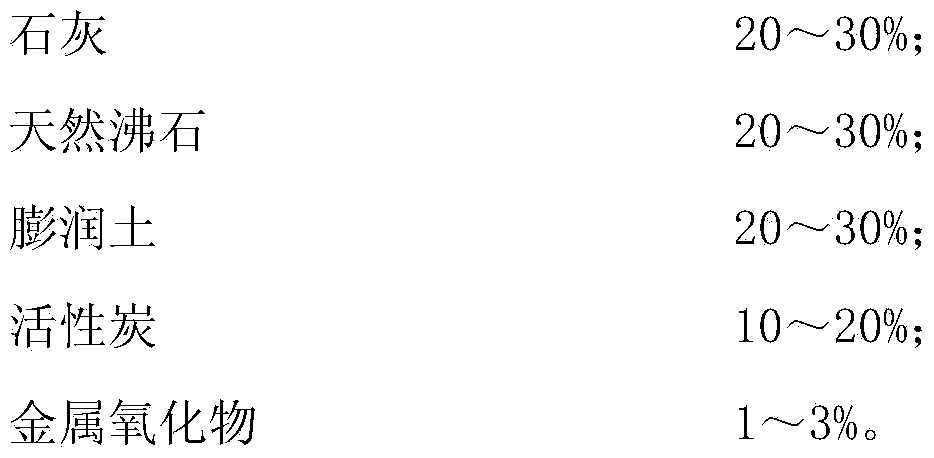

[0026] The raw material weight ratio of the adsorbent of this embodiment is lime 30%, natural zeolite 25%, sodium bentonite 23%, activated carbon 20%, metal oxide 2%, and this adsorbent is prepared by the following method: first each raw material is respectively Grinding, mixing, adding water and stirring evenly, then aging; after aging, extruding it into thin strips with a diameter of 2 mm on the extruder, and then breaking it into small sections with a length of 3 mm, and then extruding it several times to produce the finished product. The finished product is naturally air-dried at room temperature, sent to a far-infrared drying oven, and dried to a constant mass to become the finished adsorbent.

[0027] After testing, the inle...

Embodiment 2

[0031] This example is an example of high-concentration nitrogen oxide treatment, and the exhaust gas is NO-containing gas produced by silver dissolution x Exhaust gas, the gas volume is 1000~8000m 3 / h fluctuates.

[0032] The weight ratio of the raw materials of the adsorbent in this embodiment is 30% of lime, 25% of natural zeolite, 25% of sodium bentonite, 19% of activated carbon, and 1% of metal oxide; Grind, add water, mix and stir evenly, and then age; then, extrude it into thin strips with a diameter of 2.5 mm on the extruder, and then break it into small pieces with a length of 4 mm. After multiple extrusions, the finished product is produced. Naturally air-dried at room temperature, sent to a far-infrared drying box, and dried to a constant mass to become the finished product of the adsorbent.

[0033] NO in this example x Before entering the adsorption device, the waste gas is treated in the purifier equipped with the adsorbent of this embodiment after multi-stag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com