Biocompatible hydrophilic magnetic sludge fine aggregate carrier and preparation method thereof

An affinity, biological technology, applied in biological water/sewage treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. Insufficient effect, consumption of solid waste and other problems, to achieve the effect of biological hydrophilicity and good sewage treatment effect, increase the amount of organisms, and speed up the film hanging speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

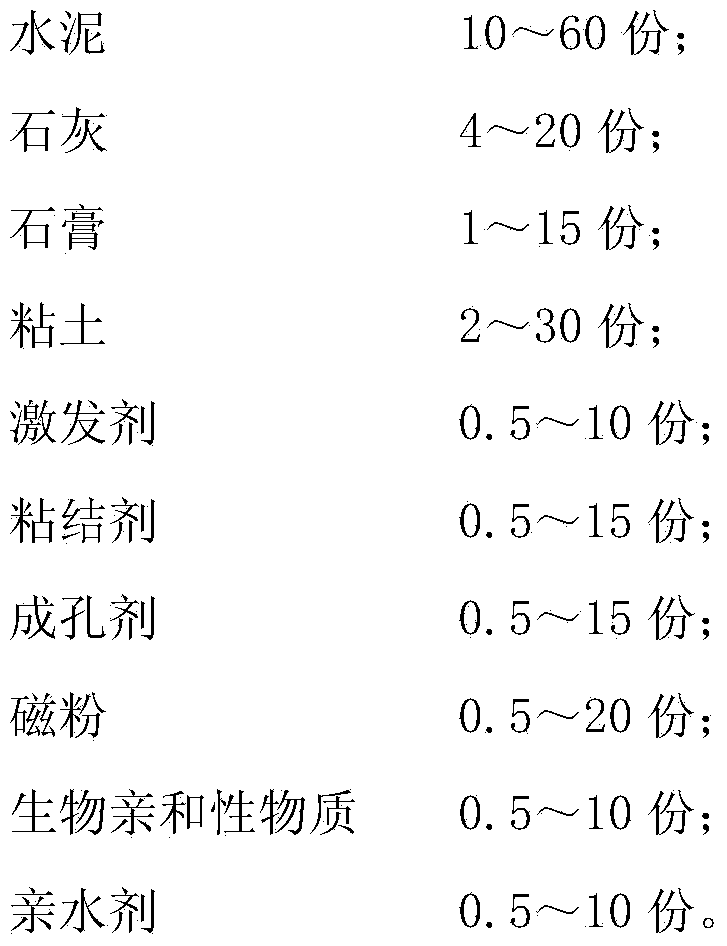

[0037] Bio-affinity and hydrophilic magnetic sludge clay sand carrier, made of at least the following components by weight: 15 parts of sludge, 41 parts of fly ash, 15 parts of Portland cement, 8 parts of lime, 2 parts of gypsum, clay 2 parts, 2 parts of sodium hydroxide, 5 parts of water glass, 2 parts of sodium bicarbonate, 5 parts of alnico magnetic powder, 1 part of chitosan and stearic acid with a mass ratio of 1:1, and 2 parts of polyacrylic acid.

[0038] Its preparation method comprises the following steps:

[0039] (1) Grind fly ash, cement, clay, lime, gypsum, and magnetic powder, pass through a 140-mesh sieve, and dry at 100°C;

[0040] (2) The activator and the binder are respectively configured into an aqueous solution; the concentration of the activator aqueous solution is 2.86mol / L; the concentration of the binder aqueous solution is 2.34mol / L;

[0041] (3) Mixing and forming into balls: take fly ash, cement, lime, gypsum, sludge, magnetic powder, clay, pore-fo...

Embodiment 2

[0048] Bio-affinity and hydrophilic magnetic sludge clay sand carrier, made of at least the following components by weight: 10 parts of sludge, 50 parts of fly ash, 10 parts of Portland cement, 10 parts of lime, 1 part of gypsum, and 10 parts of clay 0.5 parts of potassium hydroxide, 0.5 parts of white latex, 0.5 parts of hydrogen peroxide, 10 parts of iron-chromium-cobalt magnetic powder, 0.5 parts of calcium carbonate, and 0.5 parts of polyacrylic acid.

[0049] Its preparation method comprises the following steps:

[0050](1) Grind fly ash, cement, clay, lime, gypsum, and magnetic powder, pass through a 100-mesh sieve, and dry at 90°C;

[0051] (2) The activator and the binder are respectively configured into an aqueous solution; the concentration of the activator aqueous solution is 2mol / L; the concentration of the binder aqueous solution is 3mol / L;

[0052] (3) Mixing and forming into balls: take fly ash, cement, lime, gypsum, silt, magnetic powder, clay, pore-forming ag...

Embodiment 3

[0059] Bio-affinity and hydrophilic magnetic sludge clay sand carrier, made of at least the following components by weight: 60 parts of sludge, 10 parts of fly ash, 60 parts of Portland cement, 4 parts of lime, 15 parts of gypsum, clay 30 parts, 10 parts of magnesium hydroxide, 10 parts of white latex, 10 parts of aluminum powder, 0.5 parts of ferrite magnetic powder, 10 parts of calcium alginate and hydroxyapatite with a mass ratio of 3:7, 10 parts of polyethylene glycol .

[0060] Its preparation method comprises the following steps:

[0061] (1) Grind fly ash, cement, clay, lime, gypsum, and magnetic powder, pass through a 200-mesh sieve, and dry at 110°C;

[0062] (2) The activator and the binder are respectively configured into an aqueous solution; the concentration of the activator aqueous solution is 3mol / L; the concentration of the binder aqueous solution is 2mol / L;

[0063] (3) Mixing and forming into balls: take fly ash, cement, lime, gypsum, sludge, magnetic powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com