Applying method of zinc electrode additive in zinc and nickel secondary battery

An application method and secondary battery technology, applied in the direction of battery electrodes, circuits, electrical components, etc., can solve the problem of low specific discharge capacity, failure to meet the needs of zinc-nickel secondary batteries, and failure to improve the cycle performance of zinc negative electrodes, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033]36 parts by mass of analytically pure zinc nitrate hexahydrate and 10 parts by mass of analytically pure aluminum nitrate nonahydrate were dissolved in 100 parts by mass of deionized water, and 1.5 parts by mass of analytically pure tin dichloride was dissolved in 50 parts by mass of In dilute hydrochloric acid (0.1%), the above two solutions were mixed uniformly to form a salt solution. 3.2 parts by mass of sodium hydroxide and 2.12 parts by mass of sodium carbonate were dissolved in 50 parts by mass of deionized water to form an alkaline solution. Under strong mechanical stirring, drop the salt solution and alkali solution into a three-necked bottle filled with 50 parts by mass of deionized water under the protection of an inert gas at a rate of one drop per second, control the pH of the solution to 10.0, and continue stirring for 60 minutes , hydrothermal reaction at 120°C for 12h, and finally filter, wash the precipitate, and dry at 60°C for 12h to obtain the carbona...

Embodiment 2

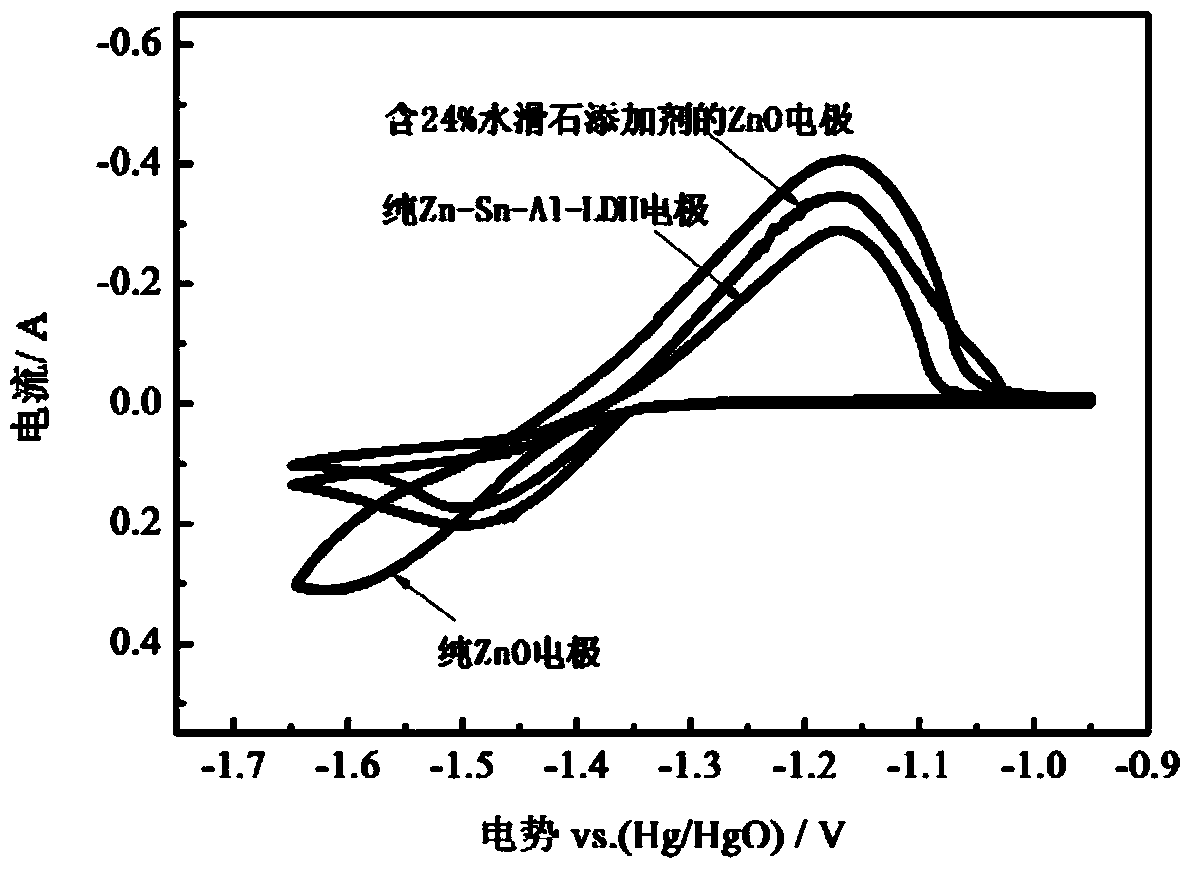

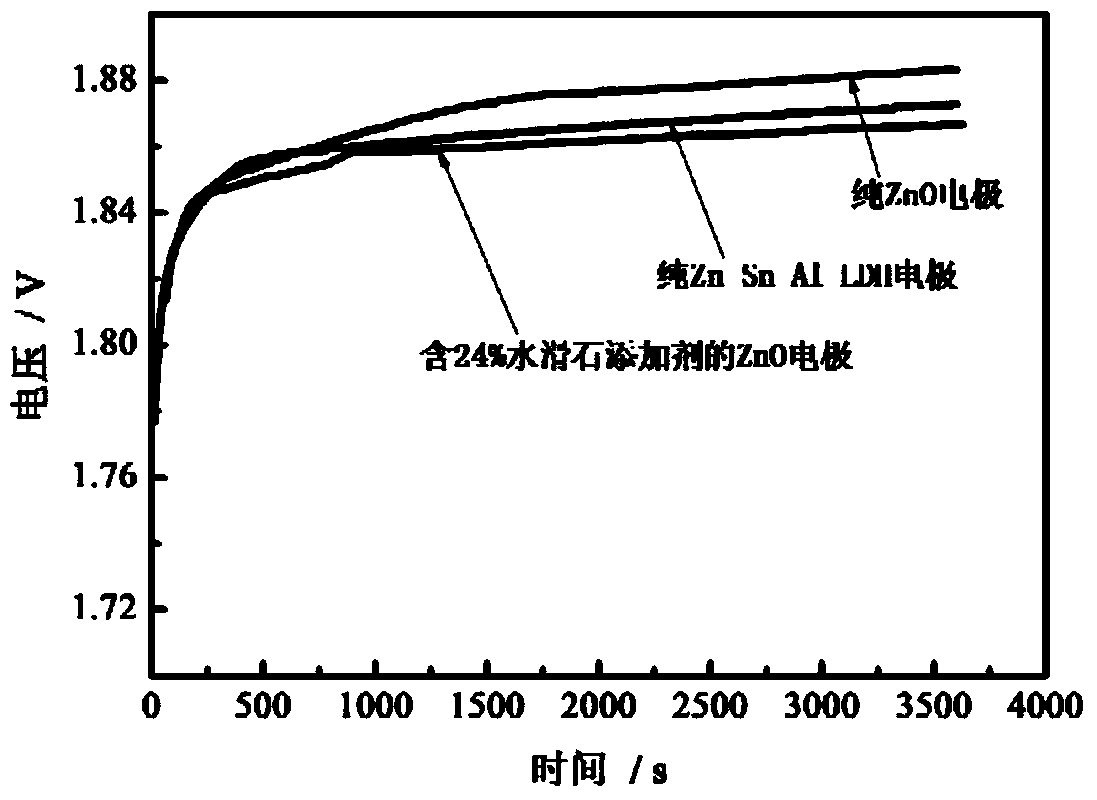

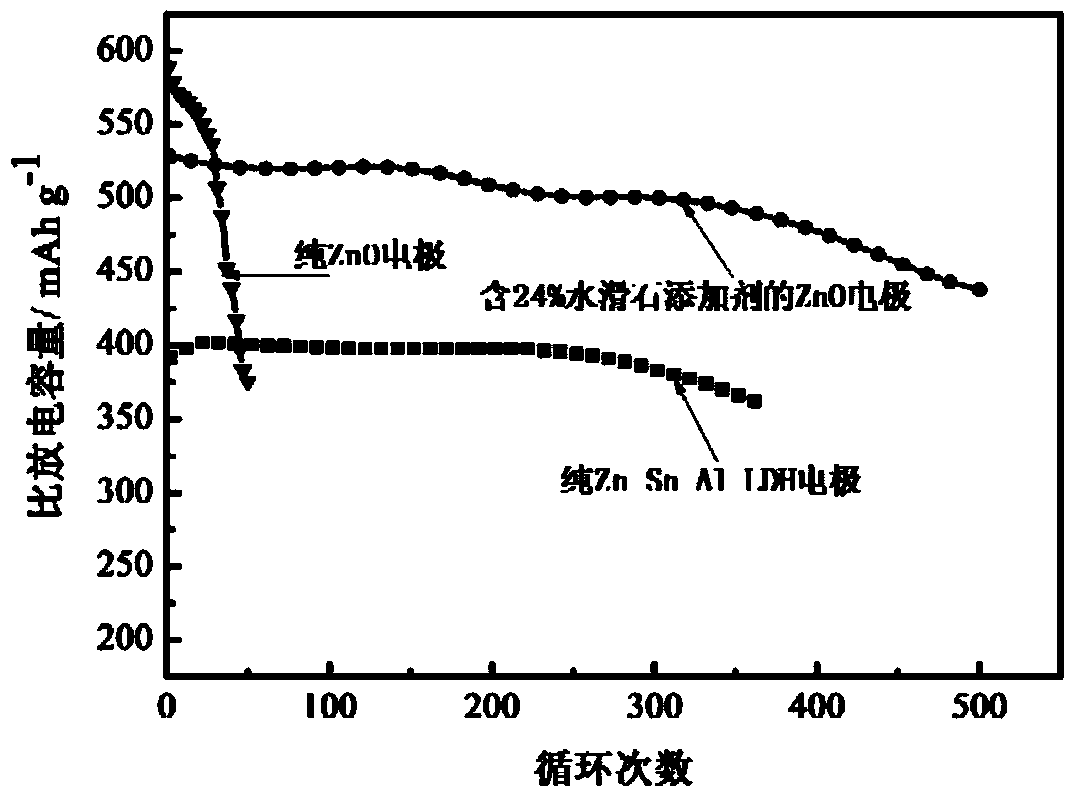

[0036] The zinc-tin-aluminum ternary hydrotalcite additive 1.2g that embodiment 1 obtains, zinc oxide 2.8g, acetylene 0.5g, zinc powder 0.5g are ground in mortar and mix and obtain negative electrode material mixture; Sodium dialkylbenzene sulfonate was dissolved in 1ml deionized water, and the resulting solution was added dropwise to the negative electrode material mixture; 0.05g binder polyvinylidene fluoride was dissolved in 6ml deionized water, and the resulting solution was added dropwise to the negative electrode material mixture Then continue to grind to a uniform slurry; roll the slurry and the glass plate into a thin sheet with a uniform thickness with a glass rod, cut it into a 1cm×1cm square piece with a blade, clamp it on a 2cm×10cm copper mesh current collector, and press it The zinc negative electrode is made, and the positive electrode is a sintered nickel positive electrode sheet with a size of 5cm×5cm. The positive and negative electrodes are respectively clamp...

Embodiment 3

[0038] The zinc-tin-aluminum ternary hydrotalcite additive 1.5g that embodiment 1 obtains, zinc oxide 2.5g, acetylene black 0.5g, zinc powder 0.5g are ground and mixed in a mortar to obtain the negative electrode material mixture; 0.1g Sodium dodecylbenzene sulfonate was dissolved in 1ml deionized water, and the resulting solution was added dropwise to the negative electrode material mixture; 0.05g binder polyvinylidene fluoride was dissolved in 6ml deionized water, and the resulting solution was added dropwise to the negative electrode material Then continue grinding to a uniform slurry; roll the slurry and the glass plate into a thin sheet with a uniform thickness with a glass rod, cut it into a 1cm×1cm square piece with a blade, clamp it on a 2cm×10cm copper mesh current collector and press it Zinc negative electrode is made of sheet, the positive electrode adopts sintered nickel positive electrode sheet with the size specification of 5cm×5cm, the positive and negative elect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com