Method for preparing monocrystal bismuth titanate nanosheet

A technology of bismuth titanate and nanosheets, applied in the direction of single crystal growth, nanotechnology, single crystal growth, etc., can solve the problems of irregular powder morphology, uneven particle size distribution, affecting material properties, etc., and achieve the reaction time. The effect of short time, lower reaction temperature and simple equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

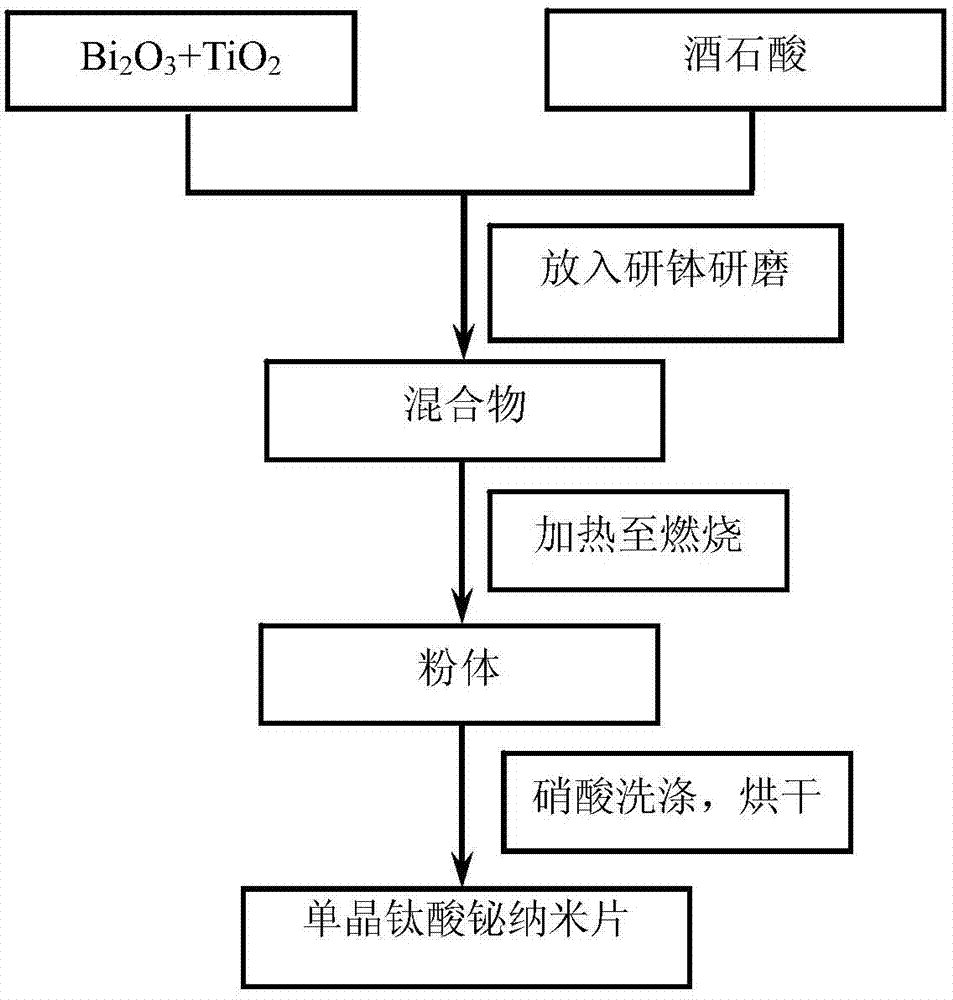

[0028] Such as figure 1 As shown, the Bi of this embodiment 4 Ti 3 o 12 The preparation process includes the following steps:

[0029] According to Bi 4 Ti 3 o 12 Chemical formula, weigh 4mmol Bi 2 o 3 and 6mmol TiO 2 . The weighed Bi 2 o 3 and TiO 2 Put it into a ceramic mortar, add 84mmol tartaric acid, and after fully grinding in the ceramic mortar for 10 minutes, move the mixture to a crucible; put the crucible in a heating mantle and heat it to 250°C, and the mixture starts to burn; after the combustion is complete, naturally cool to room temperature , wash the obtained powder with 3mol / L dilute nitric acid to remove unreacted Bi 2 o 3 and TiO 2 , and then washed with deionized water until neutral, and dried in an oven at 85° C. to obtain the product bismuth titanate nanopowder, and the bismuth titanate is a nanosheet.

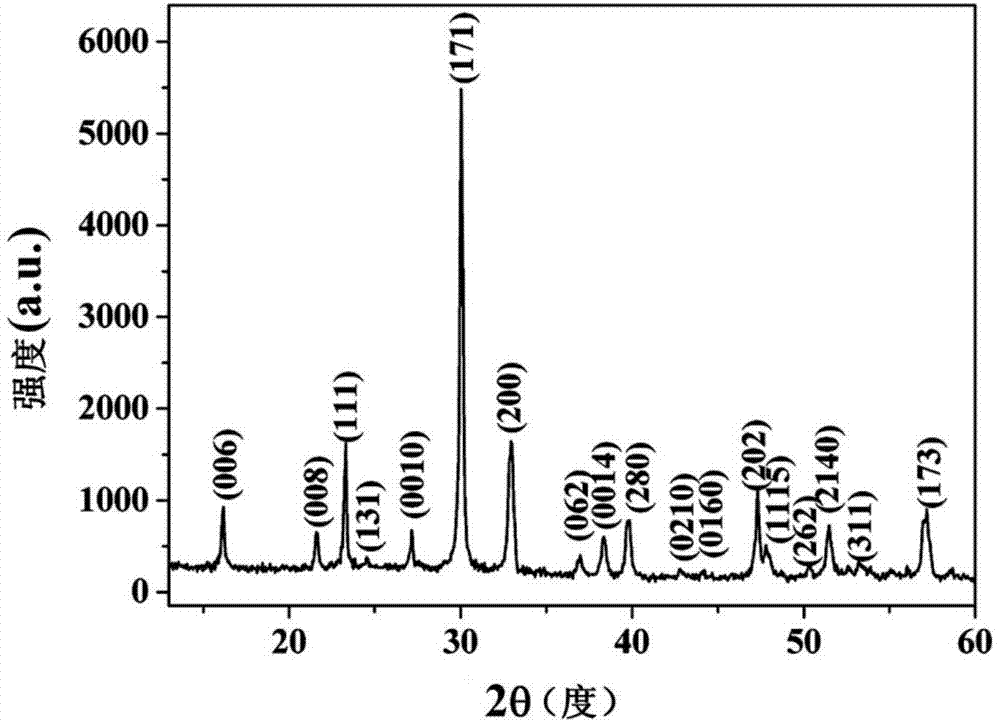

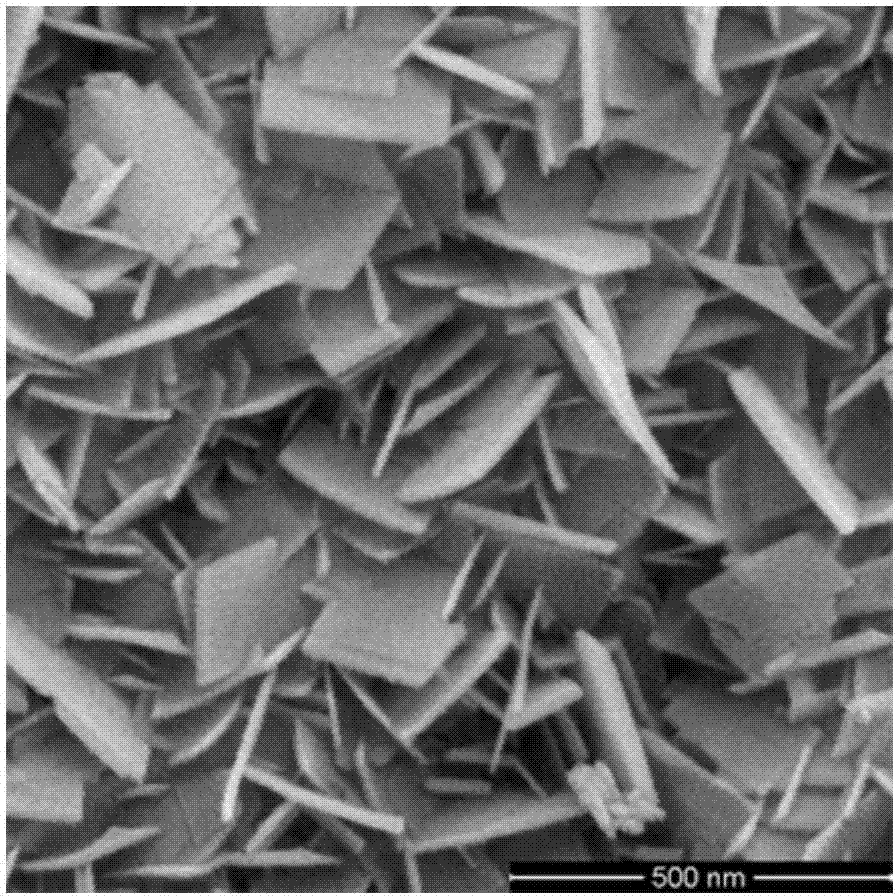

[0030] figure 2 For the prepared Bi of embodiment 1 of the present invention 4 Ti 3 o 12 X-ray diffraction pattern of the powder. D...

Embodiment 2

[0035] Bi of this embodiment 4 Ti 3 o 12 The preparation process comprises the following steps: according to Bi 4 Ti 3 o 12 Chemical formula, weigh 2mmol Bi 2 o 3 and 3 mmol TiO 2 . The weighed Bi 2 o 3 and TiO 2 Put into a ceramic mortar, add 45mmol sucrose, fully grind in the ceramic mortar for 8 minutes, move the mixture to a crucible; put the crucible in a heating mantle and heat it to 300°C, and the mixture starts to burn; after the combustion is complete, cool it naturally to room temperature, Wash the obtained powder with 2mol / L dilute nitric acid to remove unreacted Bi 2 o 3 and TiO 2, washed with deionized water until neutral, and dried in an oven at 85°C to obtain a single crystal bismuth titanate nanosheet with an edge size of about 150-250nm and a thickness of about 15-30nm.

Embodiment 3

[0037] According to Bi 4 Ti 3 o 12 Chemical formula, weigh 3mmol Bi 2 o 3 and 4.5 mmol TiO 2 . The weighed Bi 2 o 3 and TiO 2 Put it into a ceramic mortar, add 65mmol glycine, fully grind in the ceramic mortar for 10 minutes, and move the mixture to a crucible; put the crucible in a heating mantle and heat it to 300°C, and the mixture starts to burn; after the combustion is complete, cool it naturally to room temperature, Wash the obtained powder with 2.5mol / L dilute nitric acid to remove unreacted Bi 2 o 3 and TiO 2 , and then washed with deionized water until neutral, and dried in an oven at 85°C to obtain a single-crystal bismuth titanate nanosheet with an edge size of about 100-250nm and a thickness of about 20-35nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com