Clay-resistant concrete functional admixture and preparation method thereof

An admixture and concrete technology, which is applied in the field of clay-resistant concrete functional admixture and its preparation, can solve the problem that the release rate and effect of polycarboxylate superplasticizer cannot be guaranteed, and the initial dispersion performance of polycarboxylate superplasticizer cannot be guaranteed. In order to achieve the effects of increasing compactness, good dispersion and slump protection, and improving comprehensive performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

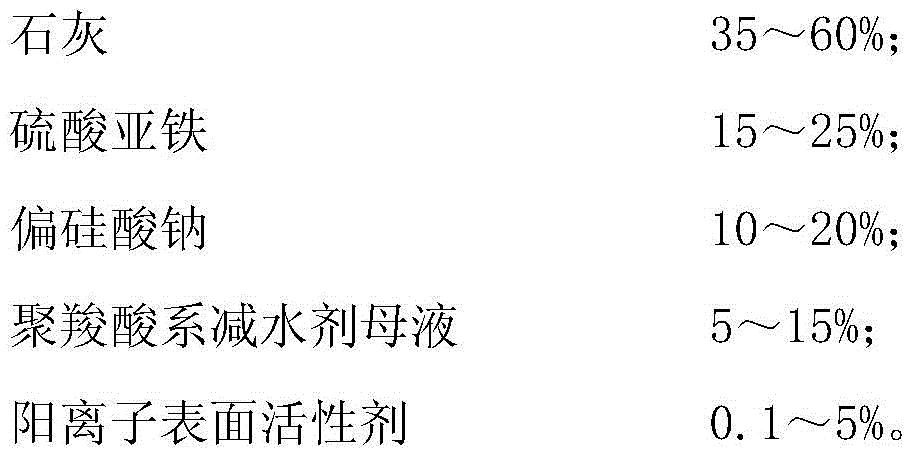

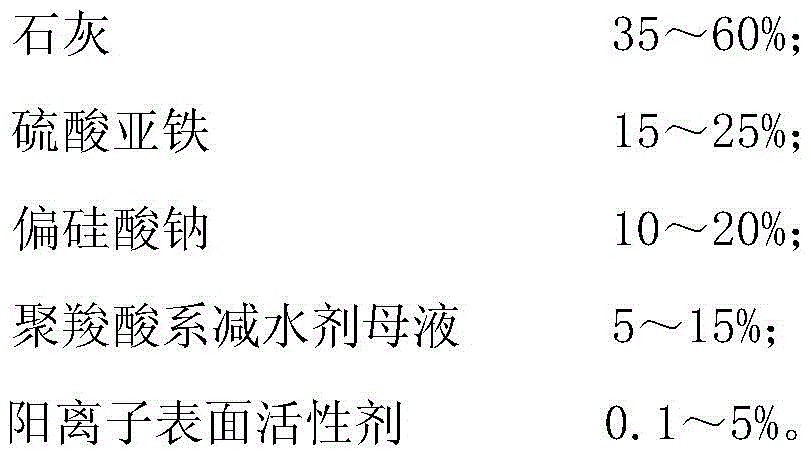

[0014] The preparation method of the above-mentioned anti-clay type concrete functional admixture comprises the following steps:

[0015] Take the components of the admixture according to the above dosage; mix the components fully in an alloy grinder, and grind them into a powder material with a fineness of 50-100 meshes. The powder material is clay-resistant Concrete functional admixture.

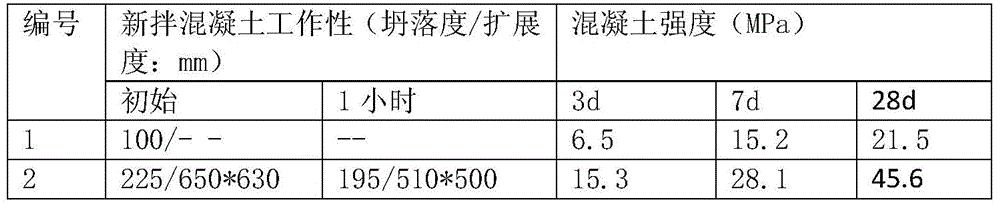

[0016] The admixture of the embodiment of the present invention is prepared by mixing and grinding quicklime, ferrous sulfate, sodium metasilicate, polycarboxylate water reducer mother liquor and other materials in proportion to a powder or paste, and preparing polycarboxylate water reducer. For water-based machine-made sand concrete with high stone powder content, natural sand concrete with high mud content, stone chip concrete, and recycled concrete, the admixture is calculated on the basis of solid content, and the amount of the cementitious material is mixed with 1 to 1.5%. Sand and g...

Embodiment 1

[0020] The present embodiment provides a kind of anti-clay type concrete functional admixture, and this admixture comprises the following components by weight: 2Kg quicklime block, 1Kg anhydrous ferrous sulfate, 0.75Kg anhydrous sodium metasilicate, 0.5Kg The mass concentration is 40% water reducing type BTC-100 polycarboxylate water reducing agent and 0.1Kg cetyl trimethyl ammonium chloride;

[0021] The preparation method is as follows: use a 50 cubic centimeter ball mill to mix 2Kg of quicklime block, 1Kg of anhydrous ferrous sulfate, 0.75Kg of anhydrous sodium metasilicate, and 0.5Kg of 40% water-reducing BTC-100 polycarboxylate The water agent and 0.1 Kg of cetyltrimethylammonium chloride were sequentially added into the mill, and poured out after grinding for 5 minutes to obtain the clay-resistant concrete functional admixture of this embodiment. For subsequent comparative experiments, the functional admixture was named BTC-750.

Embodiment 2

[0023] The present embodiment provides a kind of anti-clay type concrete functional admixture, and this admixture comprises the following components by weight: 2Kg quicklime block, 1Kg ferrous sulfate heptahydrate, 0.75Kg pentahydrate sodium metasilicate, 0.5Kg 50% mass concentration of slump-retaining water-reducing BTC-200 polycarboxylate superplasticizer and 0.1Kg of cetyltrimethylammonium chloride;

[0024] The preparation method is as follows: use a 50 cubic centimeter ball mill to mix 2Kg quicklime block, 1Kg ferrous sulfate heptahydrate, 0.75Kg sodium metasilicate pentahydrate, slump-reducing water-reducing type BTC-200 polycarboxylic acid system with a mass concentration of 50%. The water reducer and 0.1Kg of cetyltrimethylammonium chloride were added to the mill in turn, and all were poured out after grinding for 5 minutes to obtain the clay-resistant concrete functional admixture of this embodiment. For subsequent comparative experiments, the functional admixture was...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com