Amphoteric waterborne polyurethane shoe adhesive with high solid content and preparation method thereof

A water-based polyurethane, high solid content technology, applied in the direction of polyurea/polyurethane adhesive, preparation of organic compounds, preparation of amino hydroxyl compounds, etc., can solve the problems of difficult to control reaction speed, same activity, unfavorable production, etc. The effect of mechanical properties, strong cohesion and short drying time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

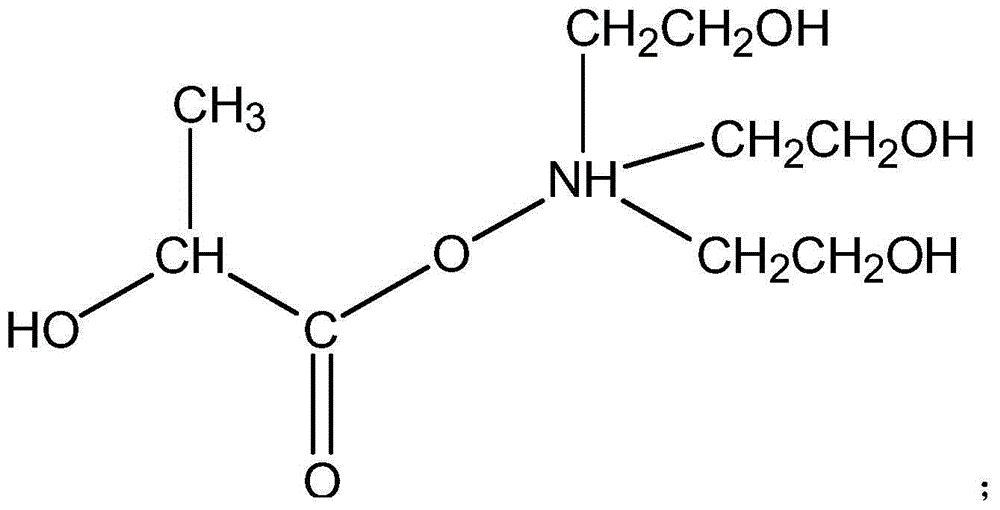

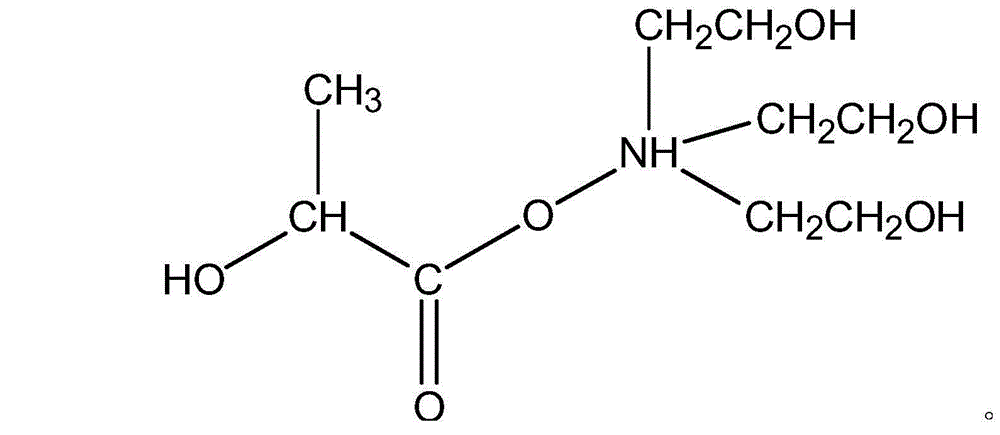

[0056] The cationic hydrophilic cross-linking agent used in the embodiment of the present invention, the preparation method is as follows:

[0057] In parts by weight, 149 parts by weight of triethanolamine and 90 parts by weight of 2-hydroxypropionic acid are uniformly dissolved in 50 parts by weight of acetone, and then added to a four-necked flask equipped with an electric stirrer and a serpentine reflux pipe, Heat up to 40-50°C, reflux at constant temperature for 0.5-1h, cool to room temperature, filter, then distill under reduced pressure at -0.1MPa vacuum and 50-55°C for 2h to remove acetone and water to obtain cationic hydrophilic crosslinking Agent, the structural formula of gained cationic hydrophilic cross-linking agent is as follows:

[0058]

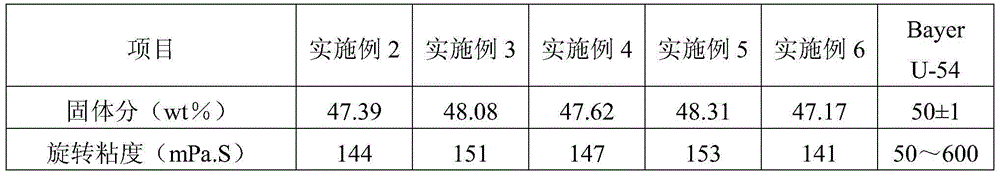

Embodiment 2

[0060] An amphoteric water-based polyurethane shoe adhesive with high solid content, the formula composition and dosage are shown in Table 1, and the specific preparation steps are as follows:

[0061] Add the formulated amount of poly-1,4-butylene adipate into a polymerization reactor equipped with a digital display electric mixer and a thermometer, raise the temperature to 120°C, distill and remove water under reduced pressure, and keep warm for 2 hours to remove water After water removal, cool down to 50-60°C; add catalysts dibutyltin dilaurate and toluene diisocyanate into the polymerization reactor, raise the temperature to 65°C, stir for 2 hours; then cool down to 60°C, add 1,4-butyl Diol and the cationic hydrophilic cross-linking agent described in Example 1 were stirred and reacted for 1.5 h; then the temperature was lowered to 55° C., acetone was added, and after stirring for 15 min, 50% mass fraction of sodium ethylenediaminoethanesulfonate aqueous solution was added,...

Embodiment 3

[0065] An amphoteric water-based polyurethane shoe adhesive with a high solid content, the formula composition and dosage are shown in Table 2, and the specific preparation steps are as follows:

[0066] Add the formulated amount of poly-1,4-butylene adipate into a polymerization reactor equipped with a digital display electric mixer and a thermometer, raise the temperature to 120°C, distill and remove water under reduced pressure, and keep warm for 2 hours to remove water After water removal, cool down to 50-60°C; add catalysts dibutyltin dilaurate and toluene diisocyanate into the polymerization reactor, raise the temperature to 65°C, stir for 2 hours; then cool down to 60°C, add 1,4-butyl Diol and the cationic hydrophilic cross-linking agent described in Example 1 were stirred and reacted for 1.5 h; then the temperature was lowered to 55° C., acetone was added, and after stirring for 15 min, 50% mass fraction of sodium ethylenediaminoethanesulfonate aqueous solution was adde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water absorption | aaaaa | aaaaa |

| water absorption | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com