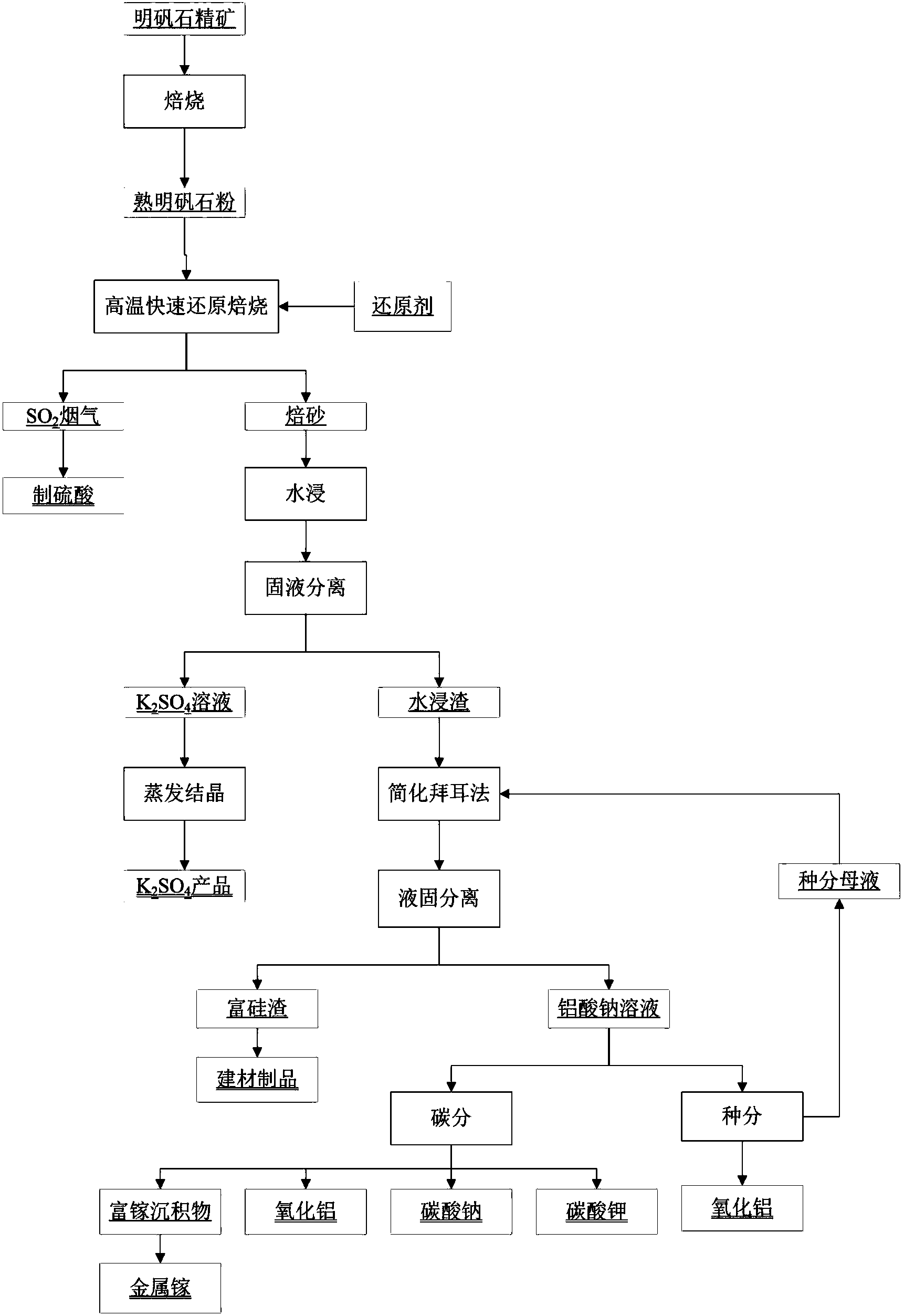

Process for recycling aluminum, potassium and gallium by quickly reducing and desulfurizing alunite at high temperature

A high-temperature, fast, alunite technology, applied in a new process of potassium and gallium, in the field of comprehensive recovery of aluminum, can solve the problems of aluminum sulfate and alumina leaching activity without special requirements, without considering the recovery of alumina and gallium, and difficult to control the roasting process. , to achieve the effect of reasonable process adaptability and applicability, low cost, and no scale restrictions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In this test, the alunite concentrate with a particle size of 200 meshes accounting for about 89% is selected. When the roasting temperature is 600 ° C and the roasting time is 10 minutes, the obtained boiled alumite powder and coal powder are mixed evenly, and the proportion of coal powder is the mass of cooked alumite powder. At a roasting temperature of 750°C, the mixture decomposes and desulfurizes quickly within 5 minutes of roasting time, and the removal rate of sulfur in the form of aluminum sulfate is 88%. The desulfurized calcined sand is leached at a temperature of 20°C for 10 minutes, a liquid-solid ratio of 2:1, 85% of potassium enters the water leaching solution, and the water leaching slag contains 0.6% sulfur. The potassium sulfate product is obtained by evaporating and crystallizing the water immersion liquid, and the crystallization mother liquid can be returned to add water to leach the new dehydration and desulfurization calcined sand.

[0051] The lo...

Embodiment 2

[0053] In this test, the alunite concentrate with a particle size of 200 meshes accounting for about 85% is selected. When the roasting temperature is 650°C and the roasting time is 30 minutes, the obtained boiled alumite powder and coal powder are mixed evenly, and the proportion of coal powder is the mass of cooked alumite powder. The mixture is rapidly decomposed and desulfurized within 3 minutes at a roasting temperature of 700°C, and the removal rate of sulfur in the form of aluminum sulfate is 80%. The desulfurized calcined sand is leached at a temperature of 20°C for 10 minutes, a liquid-solid ratio of 4:1, 87% of potassium enters the water immersion solution, and the leaching slag contains 0.7% sulfur. The potassium sulfate product is obtained by evaporating and crystallizing the water immersion liquid, and the crystallization mother liquid can be returned to add water to leach the new dehydration and desulfurization calcined sand.

[0054] The low-temperature and low-...

Embodiment 3

[0056]In this test, the alunite concentrate with a particle size of 200 meshes accounting for about 75% is selected. When the roasting temperature is 700°C and the roasting time is 60 minutes, the obtained boiled alumite powder and coal powder are mixed evenly, and the proportion of coal powder is the mass of cooked alumite powder. The mixture is rapidly decomposed and desulfurized within 8 minutes at a roasting temperature of 750°C, and the removal rate of sulfur in the form of aluminum sulfate is 90%. The desulfurized calcined sand is leached at a temperature of 90°C for 30 minutes, a liquid-solid ratio of 3:1, 89% of potassium enters the water immersion solution, and the leaching slag contains 0.35% sulfur. Evaporate and crystallize the water immersion liquid to obtain potassium sulfate, and the crystallization mother liquid can be returned to add water to leach the new dehydration and desulfurization calcined sand.

[0057] The low-temperature and low-alkali Bayer method i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com