Double-protein co-emulsification system, preparation method and application thereof

An emulsification system and double-protein technology, applied in the field of emulsification system, can solve the problems of lack of specific proteolytic enzymes, difficulty in accurately controlling the degree of hydrolysis and hydrolysis site, and high cost, so as to achieve high protein digestibility, correct amino acid score value and save Milk protein resources and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] A double protein co-emulsification system in this embodiment, its specific components and their contents are shown in Table 1, wherein the oil is soybean oil and medium-chain fatty acid ester, and the total protein in the table is soybean protein isolate (SPI) and the sum of the mass of sodium caseinate (SC).

[0051] Table 1 Components and their contents in the double protein co-emulsification system

[0052]

[0053] The preparation method of above-mentioned double protein co-emulsion system, comprises the following steps:

[0054] (1) Mix SPI and SC, disperse and dissolve in pure water, and fully hydrate with a magnetic stirrer at room temperature for 12 hours to obtain a protein solution;

[0055] (2) Stir and mix the oil and the protein solution, and disperse for 1 minute under high-speed shear at a rotating speed of 10,000 rpm to obtain coarse milk;

[0056] (3) Coarse milk is subjected to high-pressure homogenization treatment for 6 times and sterilized. Amo...

Embodiment 2

[0061] A kind of double protein co-emulsification system of the present embodiment, its each component and content are as follows:

[0062] The mass percent of soybean protein isolate and sodium caseinate in the double protein co-emulsification system is 3%,

[0063] The volume ratio of described grease and water is 8:92,

[0064] The mass ratio of the soybean protein isolate to sodium caseinate is 2:3.

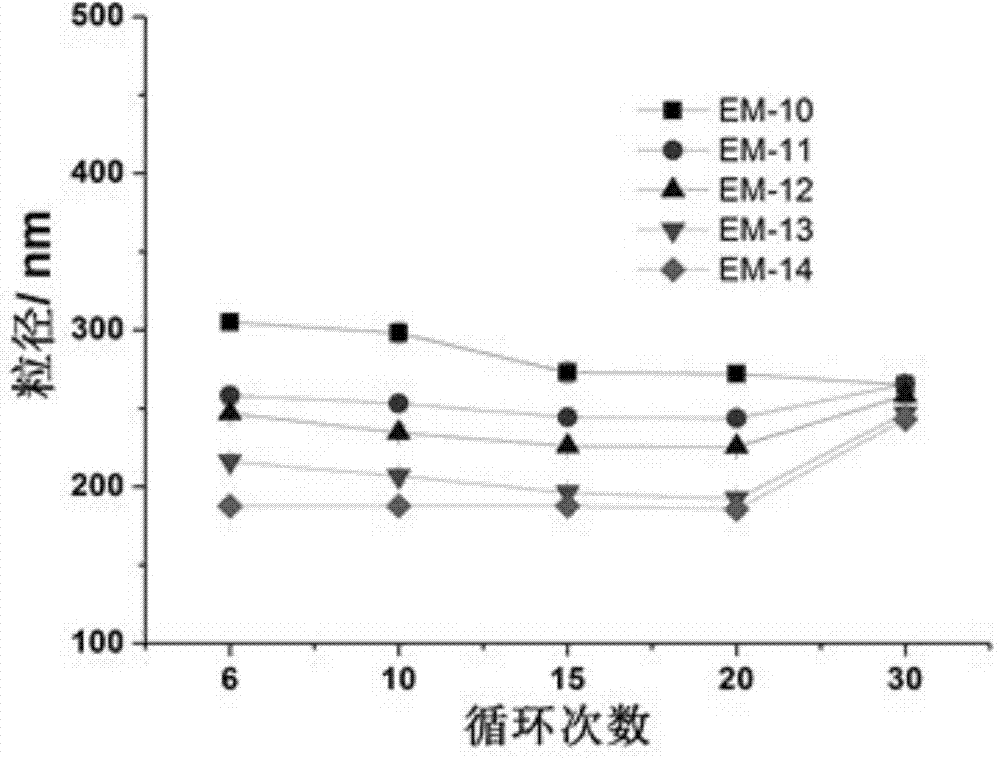

[0065] The preparation method of the above-mentioned double protein co-emulsification system is basically the same as the preparation method described in Example 1, the difference is: the shear velocity and shear time in step (2), and the first-stage homogeneous valve in step (3) Pressure and number of cycles, the specific parameters are shown in Table 2:

[0066] Table 2 shear and homogenization parameter list

[0067]

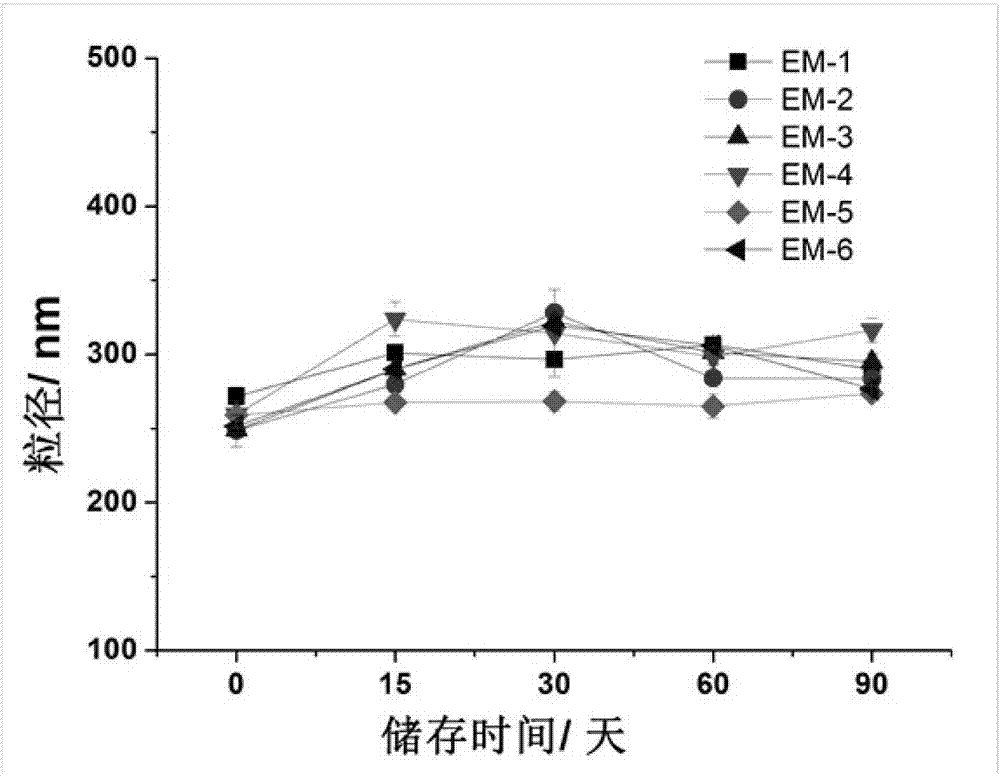

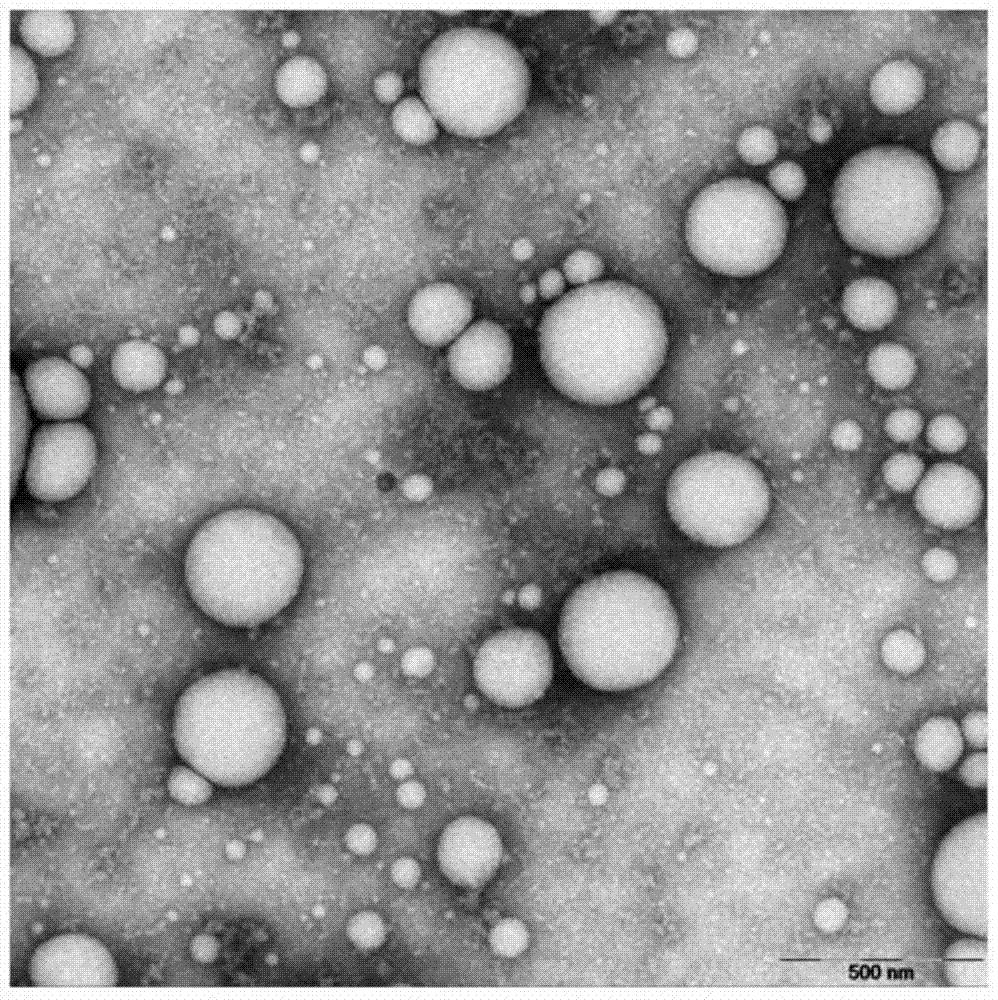

[0068] The five kinds of double protein co-emulsion systems prepared above were detected by the Malvern nanometer particle size analyzer, and their pa...

Embodiment 3

[0070] Embodiment 3 rheological experiment

[0071] 1. Purpose of the experiment

[0072] The rheology of the double protein co-emulsion system EM11 prepared in Example 2 was analyzed.

[0073] 2. Experimental method

[0074] The double protein co-emulsification system EM11 prepared in Example 2 was analyzed by Anton Paar rheometer (MCR102), the constant temperature was 25°C, and the shear rate was changed from 10S -1 Raise to 100S -1 Or fixed shear rate 10S -1 , the temperature was raised from 4°C to 50°C, and the viscosity was measured.

[0075] 3. Experimental results

[0076] For experimental results, see Figure 5 ,from Figure 5 It can be seen that the rheology of the double protein co-emulsion system prepared in Example 2 is Newtonian fluid, and the viscosity does not change with the shear rate. In the range of 4-50°C, the viscosity of the system is always less than 0.004 Pa·s. It can be seen that EM11 is a low-viscosity liquid, which is especially suitable for ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

| Electric potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com