Green synthetic method of epoxy unsaturated fatty acid methyl ester and catalyst

A fatty acid methyl ester, green synthesis technology, applied in chemical instruments and methods, organic compound/hydride/coordination complex catalysts, physical/chemical process catalysts, etc., can solve the unsatisfactory hydrophobicity and water resistance of rhenium ionic liquids , The catalytic effect is not very ideal, the double bond structure is complicated, etc., to achieve good catalytic oxidation effect, reduce the difficulty of post-processing, and strong hydrophobic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

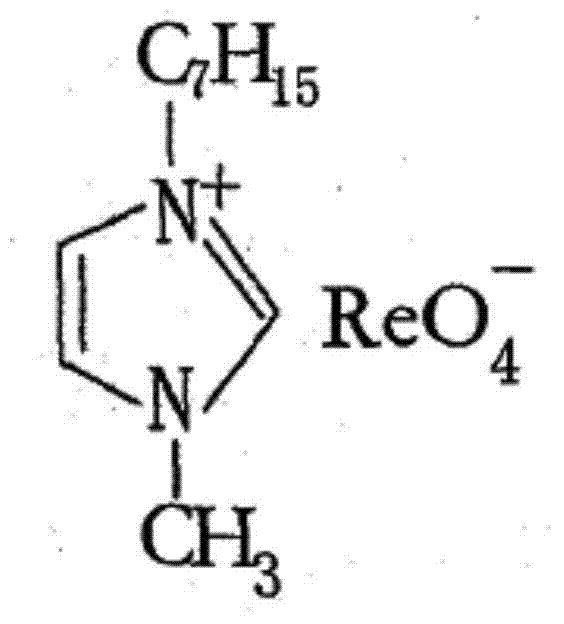

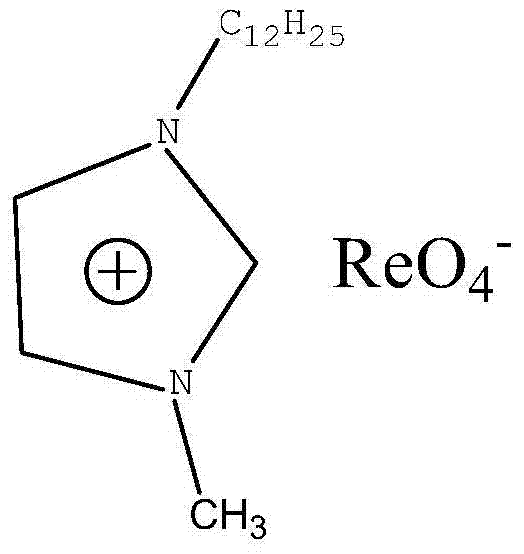

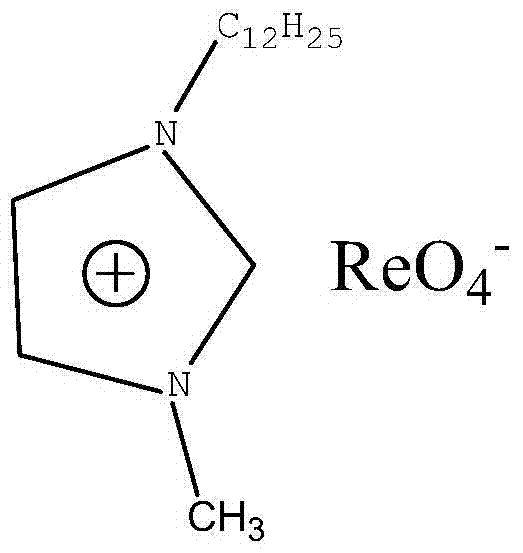

[0035] The preparation method of above-mentioned hydrophobic rhenium ionic liquid catalyst is:

[0036] Add N-methylimidazole (1mmol) and bromododecane (1.5mmol) respectively into a round bottom flask with a reflux condenser, and stir at 125-135°C for 5 hours to obtain a pale yellow viscous liquid, which is washed with ether for 3 Once, overnight at 40~50°C / 100~133Pa, a light brown waxy solid was obtained, i.e. 1-dodecyl-3-methylimidazolium bromide; 1-dodecyl-3-methylimidazolium Dissolve the bromide salt in hot distilled water, stir quickly, slowly add ammonium perrhenate aqueous solution (20ml, 0.1mol / L) dropwise, stir vigorously at 80-90°C for 6 hours, let stand, pour off the upper aqueous phase, and wash the lower layer with water The ionic liquid is neutralized, the moisture is removed in vacuum, and the vacuum is dried overnight at 60-70°C / 100-133Pa to obtain a yellow viscous liquid, that is, an alkylimidazolium-rhenium ionic liquid.

Embodiment 1

[0038] Put 500 g of unsaturated fatty acid methyl esters with an iodine value of 55% in a three-necked flask, heat to 60°C, add 1g of hydrophobic rhenium ionic liquid catalyst, add dropwise 88.35g of hydrogen peroxide with a concentration of 50%, and react at 60°C for 3 hours, Leave to stand for stratification, vacuum remove a small amount of remaining moisture in the upper oil layer, and obtain the target product epoxy fatty acid methyl ester, the epoxy value is 2.65%, and the iodine value is 5.6%. Formic acid method epoxy unsaturated fatty acid methyl ester with the same iodine value obtains epoxy fatty acid methyl ester with an epoxy value of 2.62% and an iodine value of 5.1%. The lower layer is a mixture of ionic liquid and hydrogen peroxide. The concentration of hydrogen peroxide is about 12%. After removing part of the water under reduced pressure at low temperature, the concentration of hydrogen peroxide is increased to about 30%, which is directly used for the next reac...

Embodiment 2

[0040]Place 500 g of unsaturated fatty acid methyl esters with an iodine value of 90% in a three-necked flask, heat to 50°C, add 2.5g of hydrophobic rhenium ionic liquid catalyst, add dropwise 132.52g of hydrogen peroxide with a concentration of 50%, and react at 62°C for 2 hours , leave to stand for stratification, and the upper oil layer vacuum removes a small amount of remaining moisture to obtain the target product epoxy fatty acid methyl ester, the epoxy value is 3.49%, and the iodine value is 6.0%. Formic acid method epoxy unsaturated fatty acid methyl ester with the same iodine value obtains epoxy fatty acid methyl ester epoxy value of 3.37%, iodine value of 5.7%. The lower layer is a mixture of ionic liquid and hydrogen peroxide. The concentration of hydrogen peroxide is about 14%. After removing part of the water under reduced pressure at low temperature, the concentration of hydrogen peroxide is increased to about 30%, which is directly used for the next reaction.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com