Bacillus natto and application of Bacillus natto in fermentation production of vitamin K2

A technology of Bacillus natto and vitamins, which is applied in the directions of fermentation, microorganism-based methods, bacteria, etc., can solve the problems of not mentioning the fermentation index of vitamin K2, the high price of vitamin K2, and the increase of production costs, and achieve the effect of strengthening oxygen supply. , The effect of reducing fermentation cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] Embodiment 1: strain screening

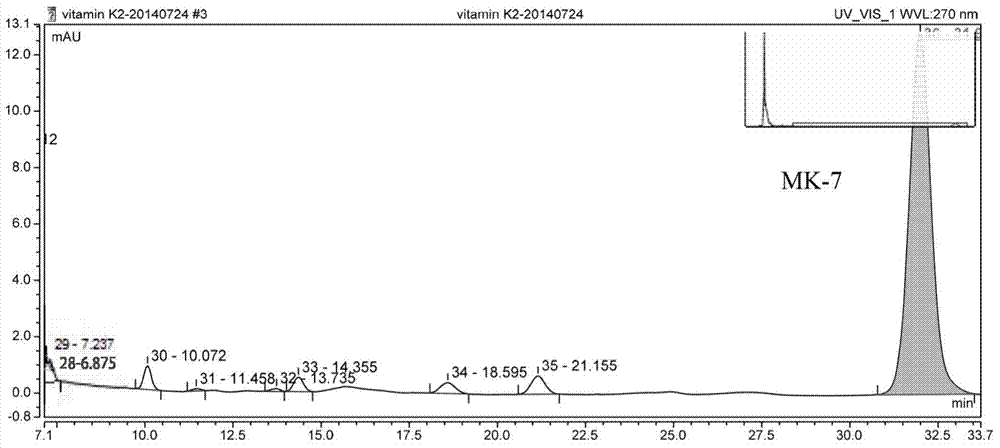

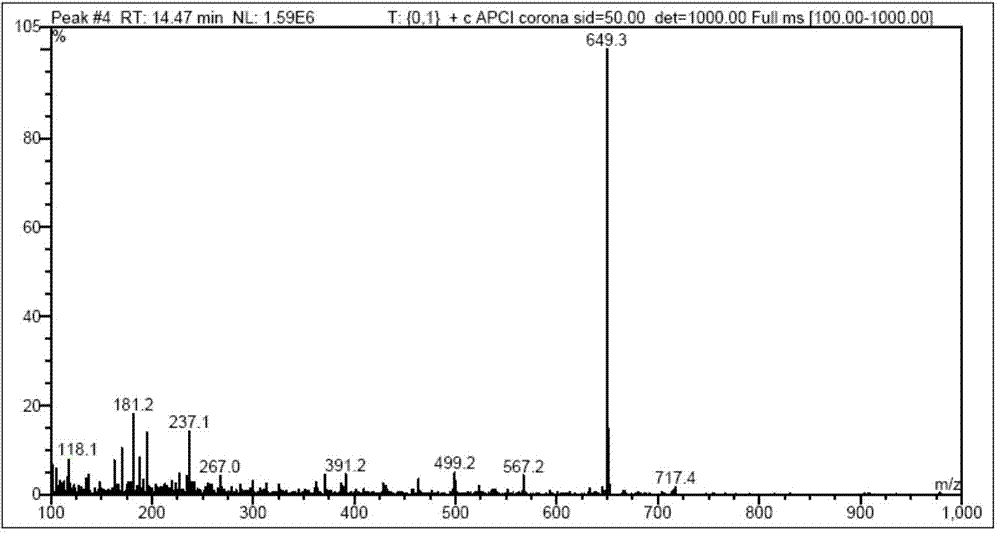

[0043] Dissolve 1g of natto product in 100ml of normal saline, oscillate and mix evenly, and dilute the sample suspension 10 times in order to prepare 10 -1 -10 -7 concentration, respectively, 10 -3 -10 -7 Draw 100ul of the dilutions from the five concentrations and add them to the screening medium for coating, apply three plates for each concentration, incubate for 48 hours at 37°C, select larger colonies that can produce hydrolysis circles, and continue to streak in the screening medium , to obtain pure bacteria, after fermentation and re-screening, high-performance liquid phase analysis and mass spectrometry identification, the bacterial strain Bacillus natto R capable of producing vitamin K2 was obtained, and the vitamin K2 produced by the bacterial strain was in the MK-7 configuration (such as figure 1 ,2).

[0044] In order to improve the ability of the bacteria to decompose protein, the obtained Bacillus natto R was subjected ...

Embodiment 2

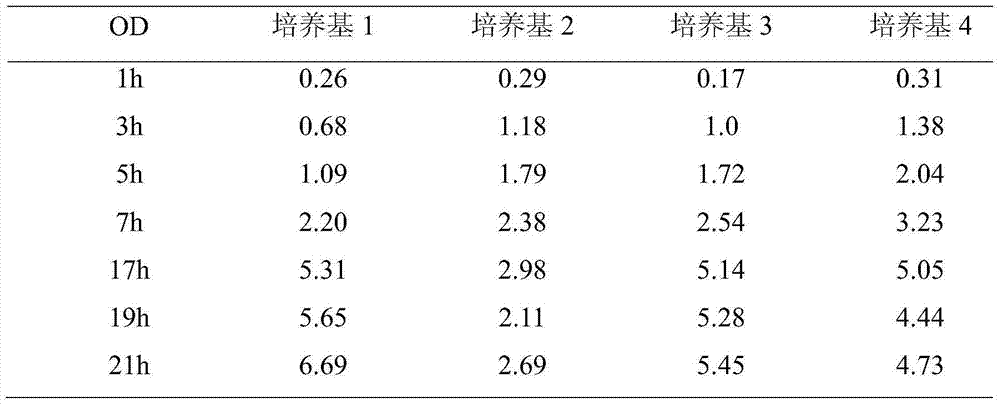

[0047] Example 2: Investigation on the basic growth performance of bacterial strains.

[0048] The bacterial strain CCTCC M 2014405 that screening obtains is carried out basic performance investigation, adopts different liquid seed culture medium to cultivate, investigates cell growth rate, and the result is shown in Table 1, and the culture medium used is (% represents the quality g of substance contained in every 100ml culture medium) :

[0049] Medium 1: 100mL bean sprout juice, 5% sucrose

[0050] Medium 2: 1% glucose, 1% peptone, 0.5% NaCl

[0051] Medium 3: 3% glucose, 4% peptone, 0.5% NaCl, 0.5% beef extract, 0.5% yeast extract

[0052] Medium 4: 0.5% glucose, 1% peptone, 0.5% NaCl, 0.5% beef extract, 0.5% yeast extract

[0053] Table 1 The growth of bacteria in different seed media

[0054]

[0055] From the above test results, except for the No. 2 medium, the other three can make the bacteria grow better, and the No. 3 medium is selected.

Embodiment 3

[0056] Example 3: Investigation on the ability of bacterial strains to accumulate vitamin K2.

[0057] Four different fermentation media were selected for fermentation, and the production capacity of vitamin K2 of the strain was preliminarily discussed. The culture temperature is 30° C., and the rotation speed is 120 rpm. (% represents the quality g of the substance contained in every 100ml medium):

[0058] Medium 1: 5% glycerol, 3% soybean peptone, 0.6g / L yeast powder, 0.3g / L K 2 HPO 4 , 0.1g / LCaCl 2 ·H 2 O, 0.3g / LMgSO 4 ·7H 2 o

[0059] Medium 2: 5% glycerol, 3% soybean powder, 0.6g / L yeast powder, 0.3mol / LK 2 HPO 4 , 0.1g / LCaCl 2 ·H2O, 0.3g / LMgSO 4 ·7H2O

[0060] Medium 3: 15g / L peptone, 25g / L yeast powder, 70g / L glycerol, 0.5g / L K 2 HPO 4 , pH7.3

[0061] Medium 4: 100mL soybean milk, 2% glucose, 0.5% NaCl, 2% NaOH to adjust pH7.0

[0062] Table 2 Comparison table of vitamin K2 produced by different fermentation media

[0063]

[0064] From the above t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com