Carbon-coated cobalt-tungsten double-metal carbide and preparation method and application thereof

A bimetallic carbide and carbon-coated technology, applied in chemical instruments and methods, chemical/physical processes, physical/chemical process catalysts, etc., can solve problems such as maintaining stability, and achieve simple synthesis steps, excellent catalytic activity and stability Good reproducibility and sample properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] 52.15mg cobalt nitrate hexahydrate, 47.87mg ammonium tungstate and 200mg dicyandiamide are evenly mixed (in this example, the ratio of the amount of the total metal substance in the two metal compounds to the amount of carbon in the nitrogen-rich organic matter is 1 :13), under inert atmosphere protection conditions, from room temperature to 700 ° C, and keep for 3 hours to obtain carbon-coated cobalt-tungsten double metal carbide.

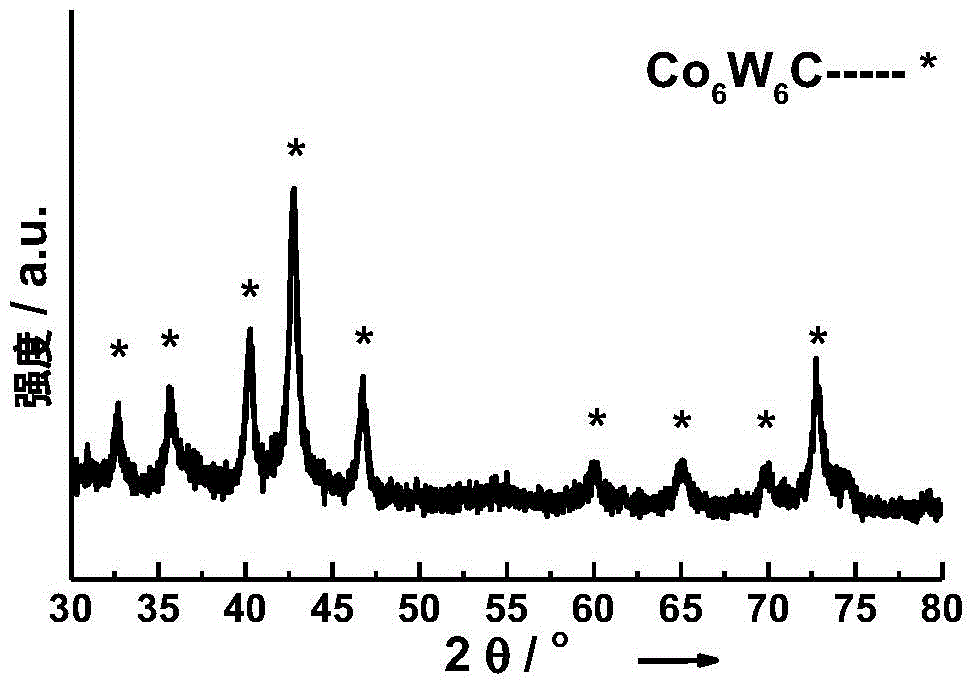

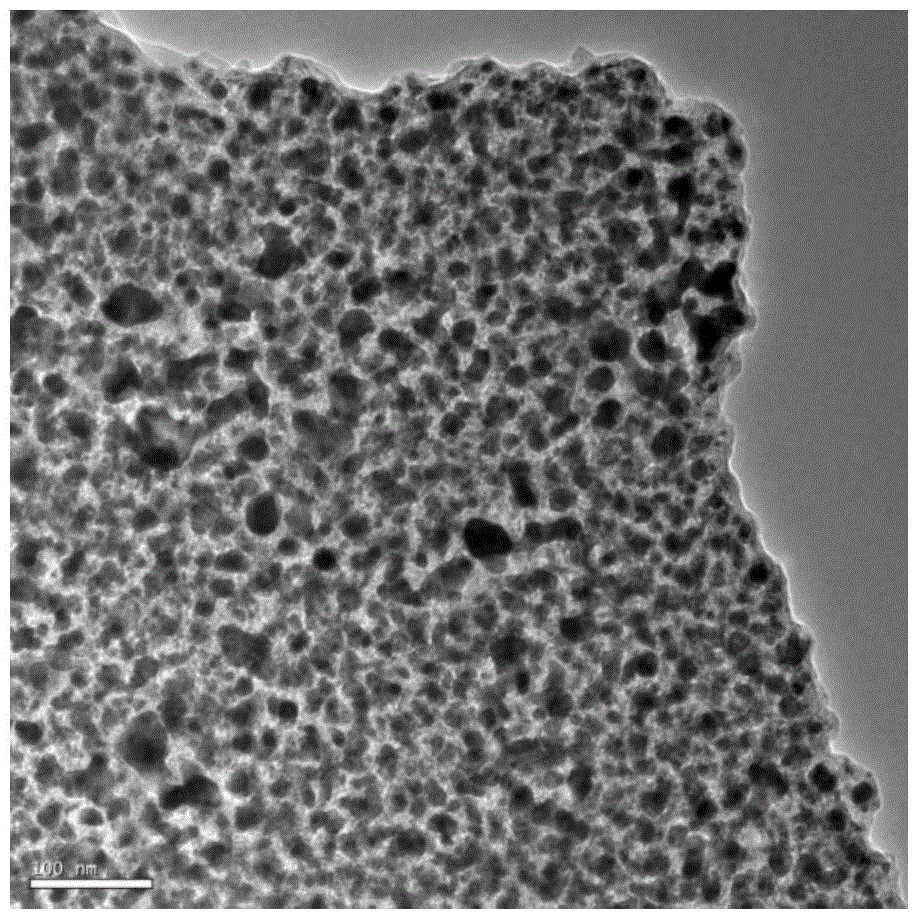

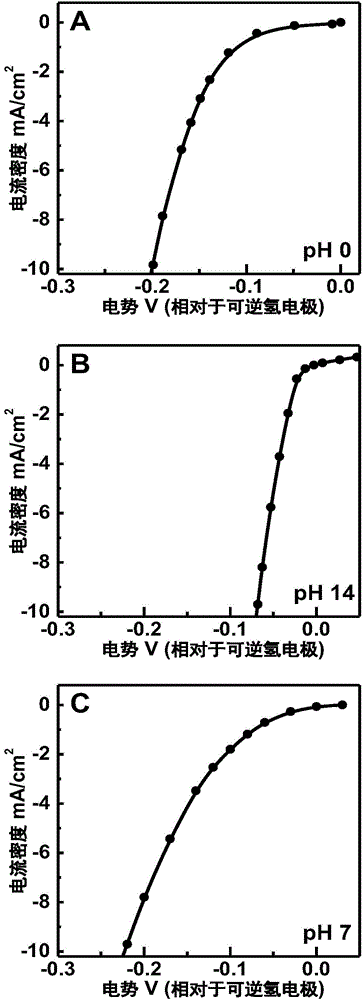

[0031] Some structural characterizations were performed on the materials prepared by the above method. figure 1 It is the XRD spectrum of the obtained material, and the peak position in the spectrum is consistent with PDF#22-0597, indicating that the substance is a cubic structure of Co 6 W 6 C; figure 2 It is the TEM image of the obtained material, it can be seen that the obtained Co 6 W 6The C cobalt-tungsten double metal carbides are uniformly distributed in the amorphous carbon thin layer in the form of nanoparticles (5-20nm), and ...

Embodiment 2

[0040] Same as Example 1, except that the calcination temperature was lowered to 650°C. Electrocatalytic properties of the obtained samples:

[0041] Under the condition of pH 0, when the overpotential is 210mV, the current density of the material reaches 10mA / cm 2 ;

[0042] Under the condition of pH 14, when the overpotential is 80mV, the current density of the material reaches 10mA / cm 2 ;

[0043] Under the condition of pH 7, when the overpotential is 230mV, the current density of the material reaches 10mA / cm 2 .

Embodiment 3

[0045] Same as Example 1, except that the calcination temperature was increased to 800°C. Electrocatalytic properties of the obtained samples:

[0046] Under the condition of pH 0, when the overpotential is 198mV, the current density of the material reaches 10mA / cm 2 ;

[0047] Under the condition of pH 14, when the overpotential is 75mV, the current density of the material reaches 10mA / cm 2 ;

[0048] Under the condition of pH 7, when the overpotential is 220mV, the current density of the material reaches 10mA / cm 2 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com