Nitrogen-doped mesoporous carbon catalyst for sewage degradation and its preparation method and application

A nitrogen-doped mesoporous carbon and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, water/sewage treatment, etc., can solve the problems of small surface area, uncontrollable structure of nitrogen-doped carbon materials, etc., to achieve The preparation method is simple and the steps are economical

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

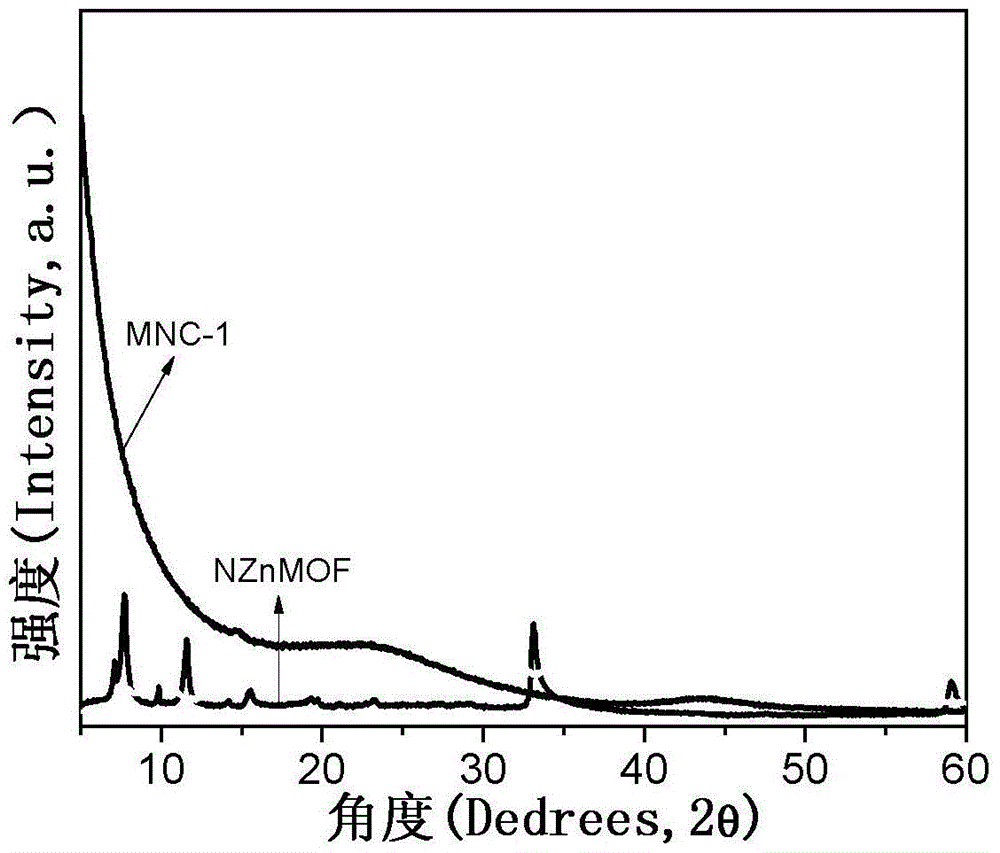

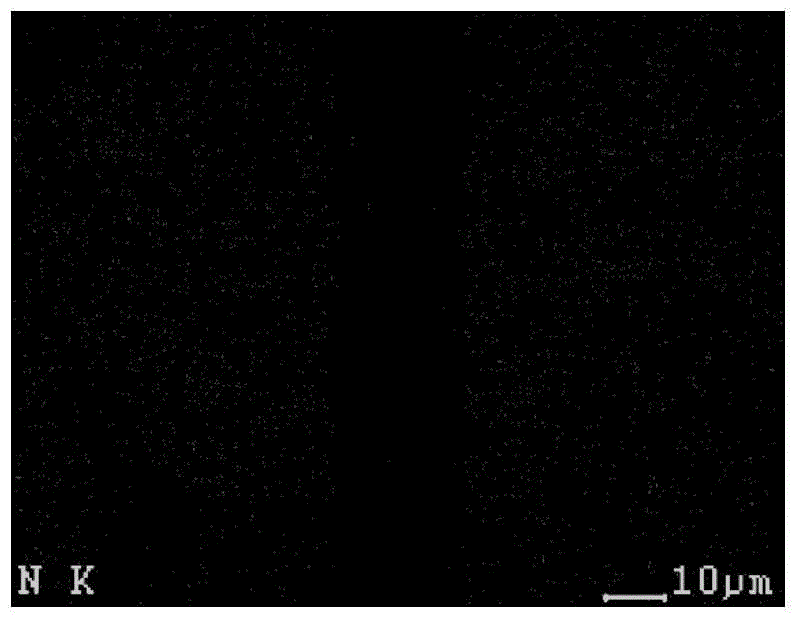

[0038] This embodiment provides a method for preparing a nitrogen-doped mesoporous carbon catalyst for sewage degradation, which includes the following steps:

[0039] Preparation of nitrogen-containing ligand 2,3-dimethyl-1,4-bis(4'-nitrobenzoic acid)butadiene:

[0040] Dissolve 57.6 g of 4-aminophenyl acid (420 mmol) in 100 mL of methanol (MeOH), add 80 drops of anhydrous formic acid, then add dropwise 17.6 mL (200 mmol) of 2,3-butanedione (dissolved in 100 mL of MeOH) , followed by stirring at room temperature for 24h; the precipitated precipitate was washed with cold MeOH at 5°C and dried in the air to obtain a light yellow powder nitrogen-containing ligand 2,3-dimethyl-1,4-bis(4'-nitrobenzoic acid ) butadiene (labeled L') with a yield of 21.8%.

[0041] Preparation of nitrogen-doped mesoporous carbon catalysts for sewage degradation:

[0042] 30mmol Zn(NO 3 ) 2 ·6H 2 O (9.0g) and 10mmol (3.25g) of ligand L' were dissolved in 50mL DMF under stirring conditions. When a...

Embodiment 2

[0051] This embodiment provides a method for preparing a nitrogen-doped mesoporous carbon catalyst for sewage degradation, which includes the following steps:

[0052] Preparation of nitrogen-doped mesoporous carbon catalysts for sewage degradation:

[0053] Dissolve 30mmol of zinc nitrate tetrahydrate and 10mmol of ligand L' in 600mL of DEF to form a uniform solution, add 15mL of triethylamine dropwise, then stir at room temperature for 1h, obtain a solid product by filtration, and then use the above solid product Wash slowly with 50-75mL DEF followed by 55mL CHCl 3 Exchange for 24 hours, repeat three times, and vacuum dry at 80°C for 5 hours to obtain nitrogen-containing zinc metal-organic framework powder (NZnMOF);

[0054] Put the NZnMOF powder obtained above in a quartz boat, raise the temperature to 910°C at a rate of 2°C / min in a nitrogen atmosphere, and then carbonize at 910°C for 4 hours in a nitrogen atmosphere to obtain a nitrogen-doped mesoporous carbon catalyst f...

Embodiment 3

[0056] This embodiment provides a method for preparing a nitrogen-doped mesoporous carbon catalyst for sewage degradation, comprising the following steps:

[0057] Dissolve 20mmol of zinc chloride and 10mmol of ligand L' in 100mL of DMAC, stir at room temperature for 0.5h, and filter to obtain a solid product, then slowly wash the above solid product with 50-75mL of DMAC, and then wash it with 60mL of CHCl 3 Exchange for 24 hours, repeat three times, and vacuum dry at 80°C for 8 hours to obtain nitrogen-containing zinc metal-organic framework powder (NZnMOF);

[0058] Put the NZnMOF powder obtained above in a quartz boat, raise the temperature to 980°C at a rate of 15°C / min in a nitrogen atmosphere, and then carbonize at 980°C for 2 hours in a nitrogen atmosphere to obtain a nitrogen-doped mesoporous carbon catalyst for sewage degradation , denoted as MNC-3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com