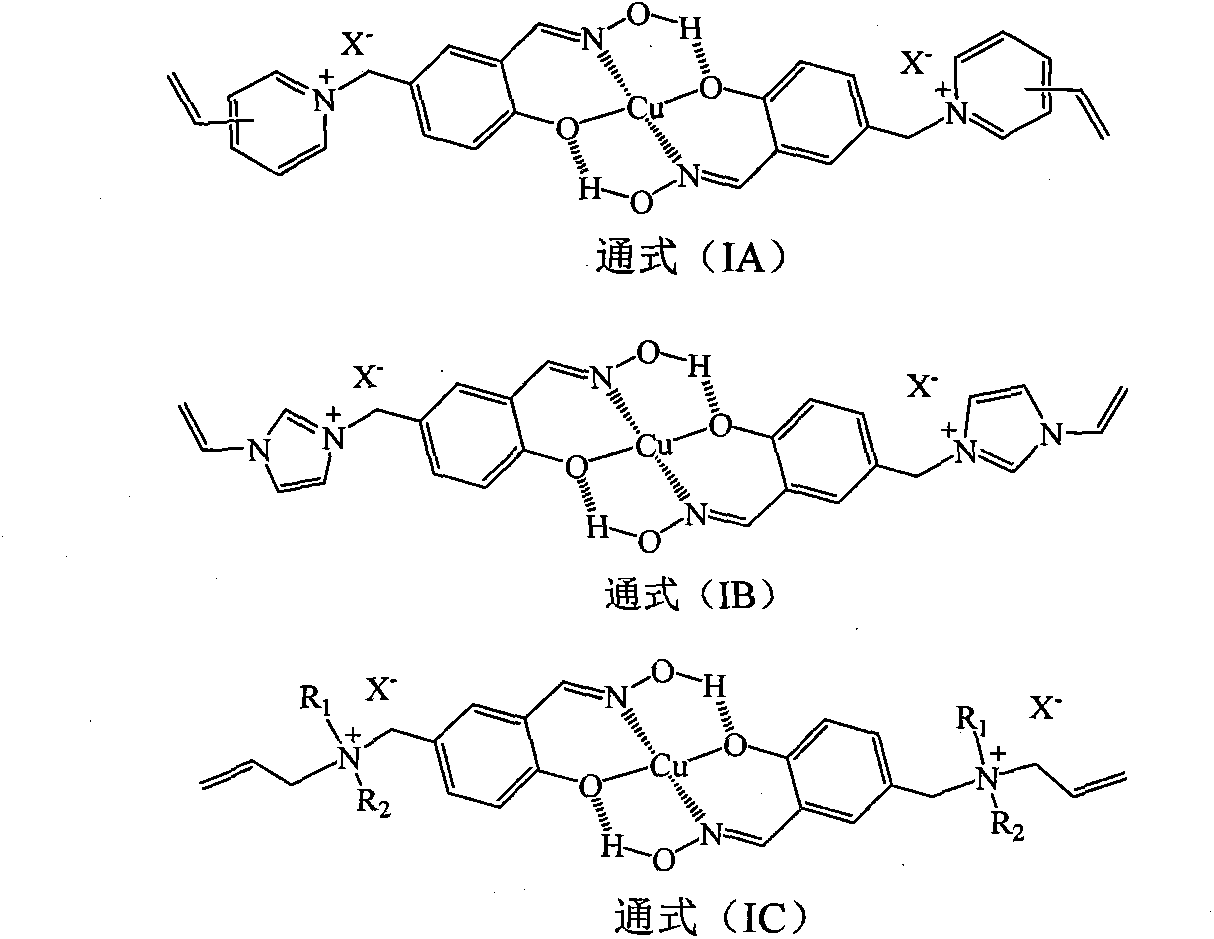

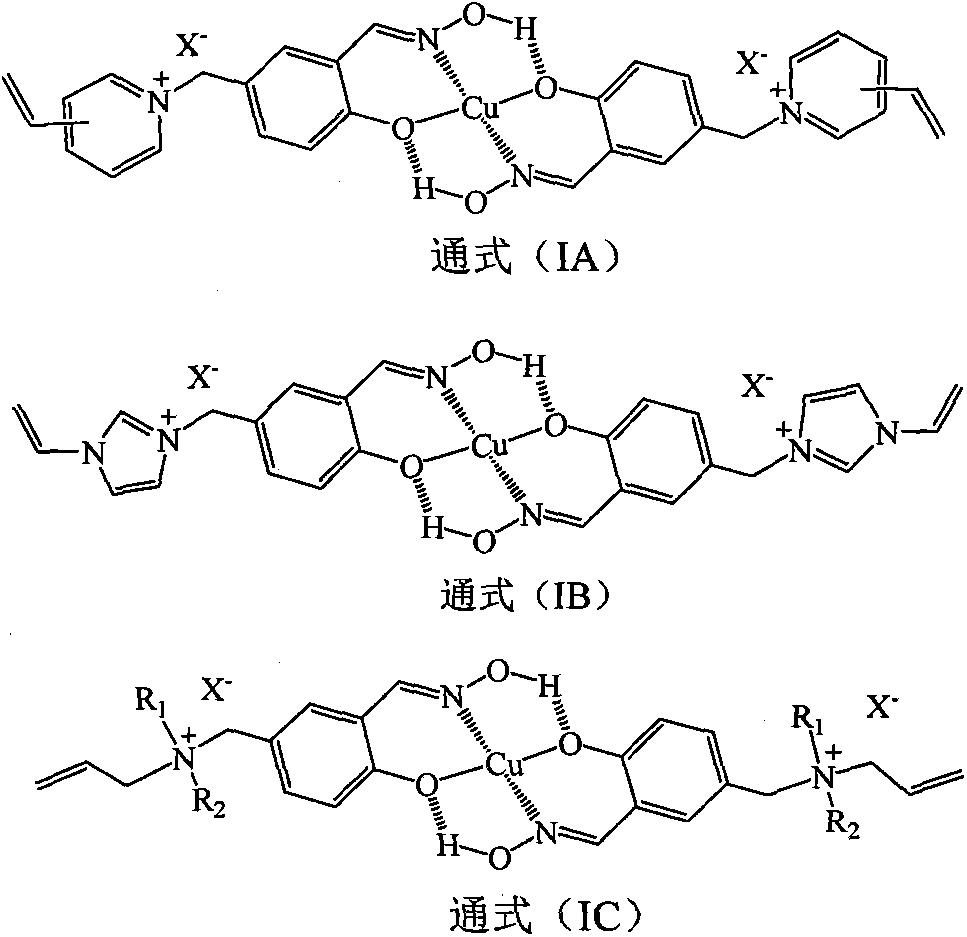

Solid phase imprinted double-position extraction agent for copper (II) and preparation method of extraction agent

An extraction agent and imprinting technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of a small amount of emulsion, prone to precipitation, complex synthesis technology, etc., to overcome strong hydrophobicity, improve water wettability and electric charge The effect of density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

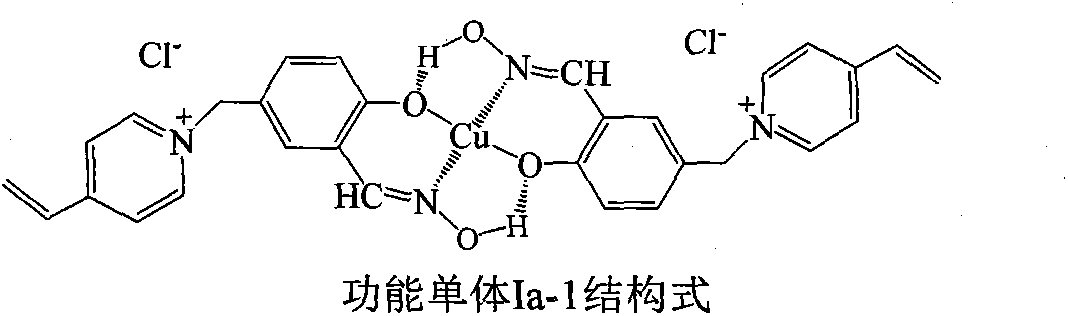

[0033] Example 1 Preparation of Hollow Resin Spherical Copper (II) Solid Phase Imprinted Dual-position Extractant (IA-1)

[0034] In the four-necked bottle, put 400 grams of polyvinyl alcohol aqueous solution with a mass percent concentration of 1.3%, start stirring, add 130 grams of magnesium sulfate, stir and dissolve, add 50 grams of functional monomer (Ia-1), N-formazan Diallylamine 18 grams, N, N-dimethylacrylamide 32 grams, ethylene glycol dimethacrylate 30 grams, N, N-dimethylacetamide 150 grams and azobisisobutyronitrile 2.8 grams The mixed solution was filled with nitrogen and deoxygenated for 30 minutes, and the stirring rate was adjusted. After the system was uniformly dispersed, the temperature was raised to 60-65°C, and the polymerization reaction was carried out for 4 hours. Filtrate to obtain chelating polymer balls; sequentially use ethyl acetate to carry out Soxhlet extraction on chelating polymer balls to remove the porogen, and use 1mol / L hydrochloric acid t...

Embodiment 2

[0037] Example 2 Preparation of Hollow Resin Spherical Copper(II) Solid Phase Imprinted Double-position Extractant (IB-1)

[0038] According to the method and operation steps of embodiment 1, the functional monomer (Ia-1) of embodiment 1 is changed into functional monomer (Ib-1), and N-methyldiallylamine is changed into dimethylaminoethyl methacrylate Ester and ethylene glycol dimethacrylate were replaced by N, N-methylenebismethacrylamide to prepare copper (II) solid-phase imprinted dual-position extractant (IB-1) hollow resin balls. According to experiments, at 25°C, the copper (II) solid-phase imprinted double-position extractant (IB-1) takes 1.3 minutes to adsorb copper (II) ions in saturation, and the copper (II) ion adsorption capacity is 84.8 mg / g.

[0039]

Embodiment 3

[0040] Example 3 Preparation of Hollow Resin Spherical Copper(II) Solid Phase Imprinted Dual-position Extractant (IC-1)

[0041]According to the method and operating steps of Example 1, the functional monomer (Ia-1) of Example 1 is replaced with a functional monomer (Ic-1), and N-methyldiallylamine is replaced with dimethylaminoethyl methacrylate. Ester, ethylene glycol dimethacrylate was replaced by N, N-methylenebismethacrylamide to prepare copper (II) solid-phase imprinted dual-position extractant (IC-1) hollow resin balls. According to experiments, at 25°C, the time for the copper (II) solid-phase imprinted double-position extractant (IC-1) to saturately adsorb copper (II) ions is 2.1 minutes, and the adsorption capacity of copper (II) ions is 76.1 mg / g.

[0042]

PUM

| Property | Measurement | Unit |

|---|---|---|

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com