Method for preparing fatty alcohol from fatty acid or fatty acid ester by selective hydrogenation

A fatty acid ester and fatty acid technology, applied in the field of catalytic hydrogenation, can solve problems such as poor catalyst reproducibility, many influencing factors of preparation methods, difficulty in unifying selectivity and conversion rate, etc., to reduce energy consumption and equipment investment, and to simplify the process The effect of green environmental protection and wide application prospect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

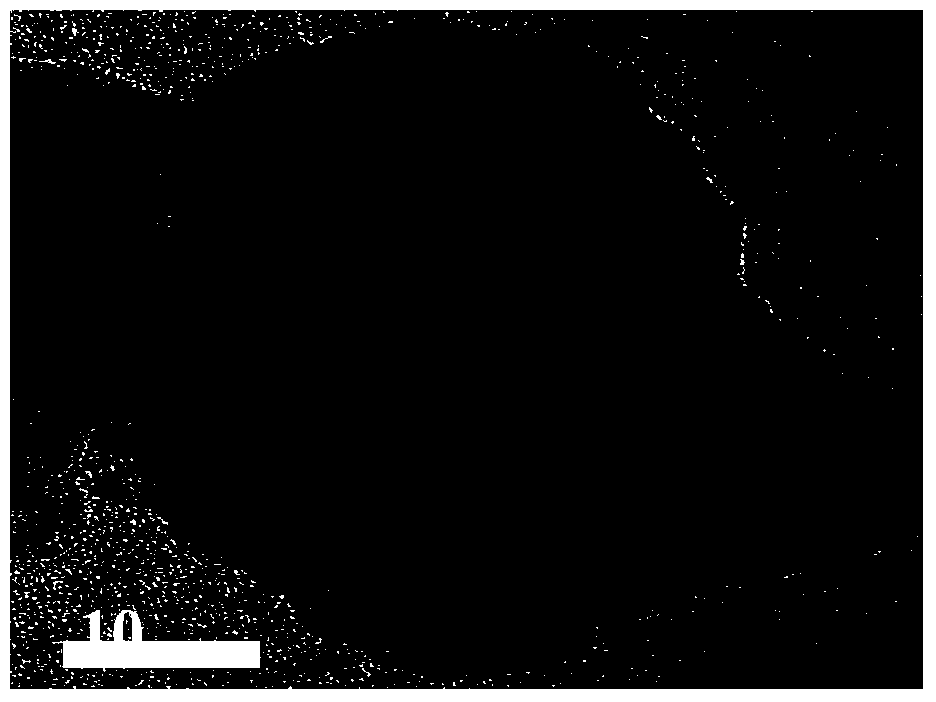

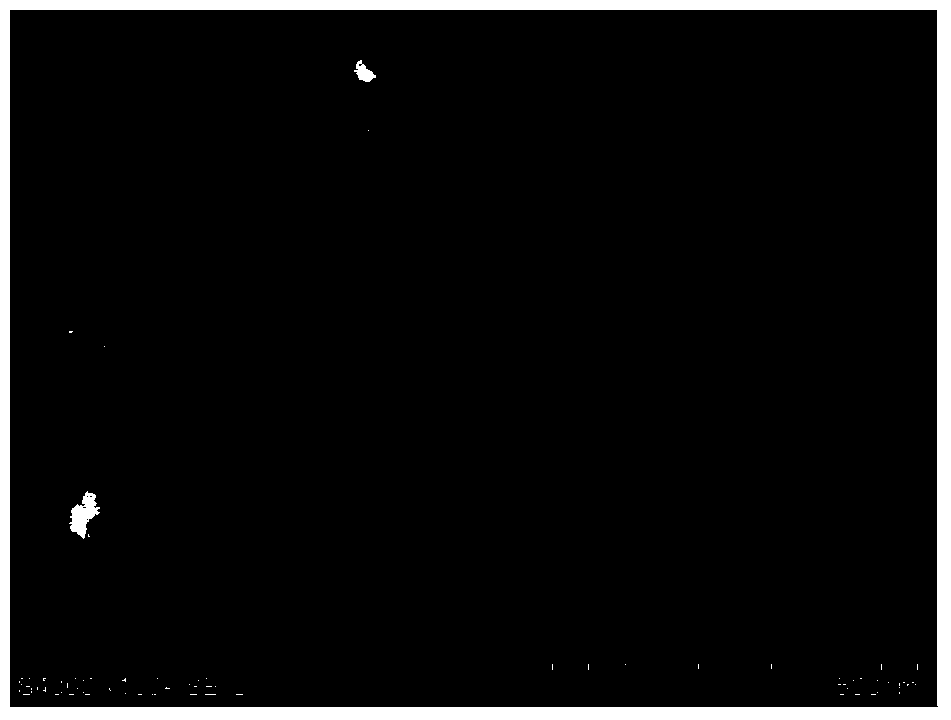

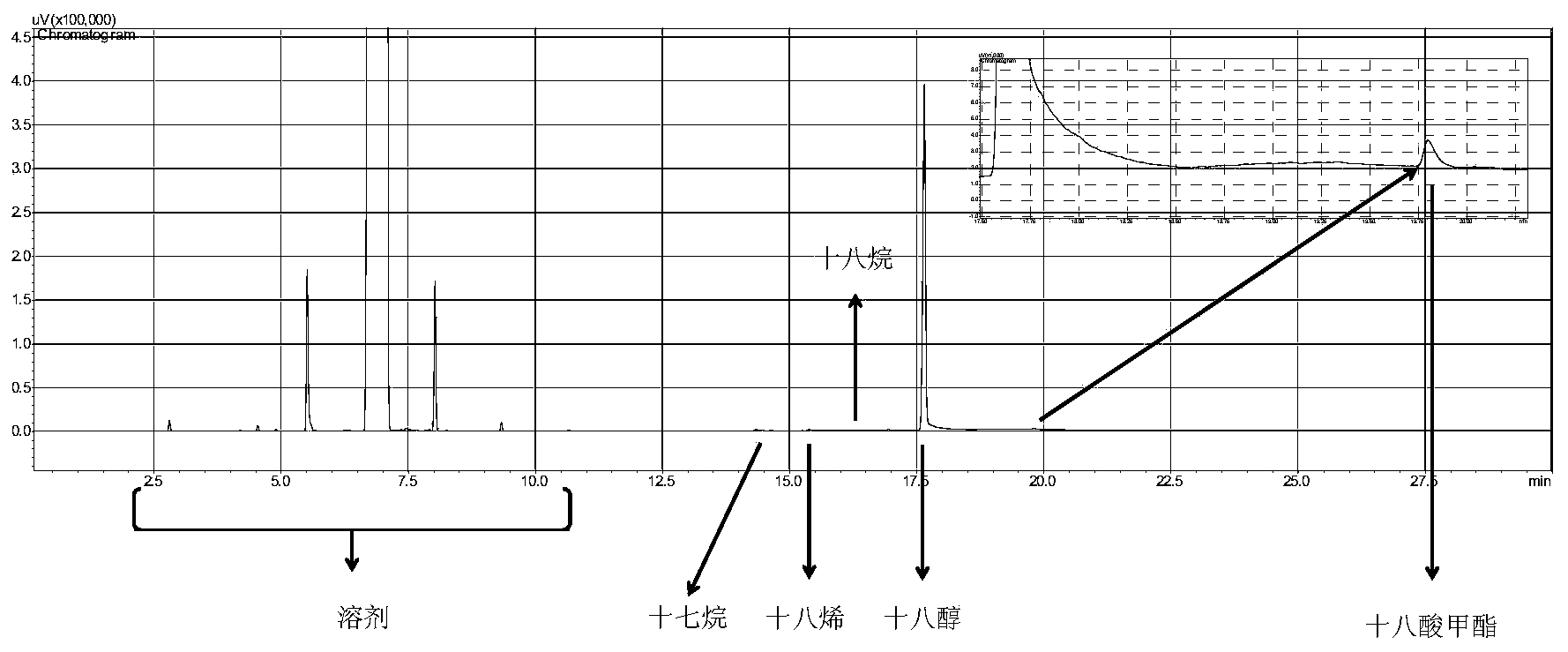

[0031] The catalyst used in this example is a supported catalyst Ru-Sn / SiO 2 (Ru supporting amount: 5wt%, Sn supporting amount: 5wt%). The loading amount of Ru measured by ICP was 5.28wt%, the loading amount of Sn was 4.83wt%, and the specific surface was measured by nitrogen adsorption to be 243m 2 g -1 , the pore volume is 0.69cm 3 g -1 , see Table 1. figure 1 The transmission electron microscope picture in shows that the particle size of Ru-Sn is about 3nm, figure 2 The SEM image of the surface in the SiO 2 The particle size is 15±5nm. :

[0032] Preparation of Supported Catalyst Ru-Sn / SiO 2 Process: Prepared by the commonly used excessive impregnation method. For specific methods, see Catalyst Carrier Preparation and Application Technology, edited by Zhu Hongfa, Petroleum Industry Press, 2002 edition. Afterwards, the catalyst was calcined at 550° C. in an atmosphere of air for 4 hours, and then at 550° C. in an atmosphere of hydrogen for 4 hours.

[0033] Weigh ...

Embodiment 2

[0039] The catalyst Ru-Sn-Pt / C used in this example was determined by ICP. The Ru loading was 10.13wt%, the Sn loading was 5.08wt%, the Pt loading was 4.91wt%, and the surface area was 529m 2 g -1 , the pore volume is 0.26cm 3 g -1 , see Table 1.

[0040] Catalyst Ru-Sn-Pt / C is prepared by using the commonly used formaldehyde reduction method. For details, see the literature Carbohydrate Research, 2011, 346(11), 1327-1332.

[0041] Weigh 5.0g of palm oil and 1.0g Ru-Sn-Pt / C (Ru loading: 10wt%, Sn loading: 5wt%, Pt loading: 5wt%) and join in the autoclave, add Fill 80mL of dodecane with 3MPa hydrogen, raise the temperature to 220°C, and react for 6h. After the reaction was finished, it was naturally cooled to room temperature, and the liquid product was taken for GC-MS combined with GC quantitative and qualitative detection. GC results showed that the conversion rate of raw materials reached 95.71%, the selectivity of cetyl alcohol reached 35.28%, and the selectivity of st...

Embodiment 3

[0044] The catalyst Ru-Pt / diatomaceous earth used in this example is determined by ICP, the Ru loading is 9.85wt%, the Sn loading is 1.89wt%, and the surface area is 51m 2 g -1 , the pore volume is 0.48cm 3 g -1 , see Table 1.

[0045] The process of preparing supported catalyst Ru-Pt / diatomite: it is prepared by the commonly used excessive impregnation method. For specific methods, see Catalyst Support Preparation and Application Technology, edited by Zhu Hongfa, Petroleum Industry Press, 2002 edition. Afterwards, the catalyst was calcined at 550° C. in an atmosphere of air for 4 hours, and then at 550° C. in an atmosphere of hydrogen for 4 hours.

[0046] Weigh 2.0g of palmitic acid and 0.2g of Ru-Pt / diatomaceous earth (Ru loading: 10wt%, Pt loading: 2wt%, see Table 1) into the autoclave, add 80mL of water, Charge 4MPa of hydrogen, heat up to 200°C and react for 2h. After the reaction, it was naturally cooled to room temperature, and the product was extracted with ethyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com