Saccharomyces cerevisiae capable of being co-fermented by a plurality of carbon sources and application thereof

A technology of Saccharomyces cerevisiae and culture, which is applied in the field of Saccharomyces cerevisiae to achieve the effect of enriching the ability of flavor metabolism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

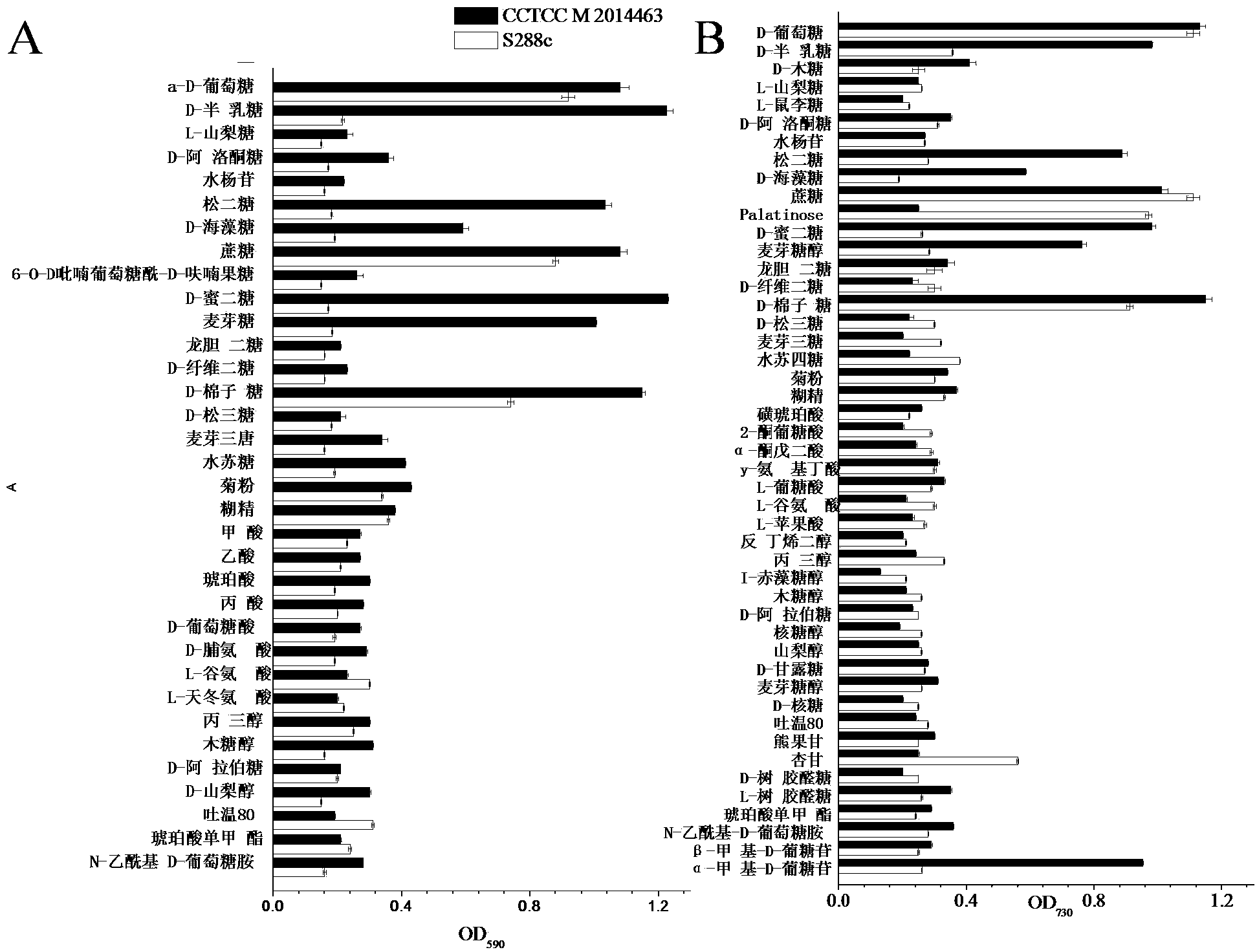

[0041] Example 1 Saccharomyces cerevisiae CCTCC NO: M 2014463 carbon source assimilation level

[0042] Biolog carbon source assimilation identification was used for culture in deep-well plates, and a single colony was picked and inoculated in YPD liquid medium at 200 rpm and 30°C for 16-20 hours to obtain seed liquid. Dilute the seed solution with saline to OD 600 After = 0.05, transfer to biolog YT microwell identification plate (purchased from Huayuehang Instrument Co., Ltd.), inoculate 100 μL, incubate at 28°C for 72 hours, and measure OD 590 and OD 730 . Among them, OD 590 、OD 730 When it is greater than 0.2 and less than 0.8, it means that the carbon source can be utilized but the degree of utilization is not high; OD 590 、OD 730 When it is greater than 0.8, it means that the carbon source can be well utilized. The biolog has done 2 parallels, and the meaning marked with * on the graph means P<0.05 by one-way ANOVA analysis.

[0043] The result is as figure 2 S...

Embodiment 2

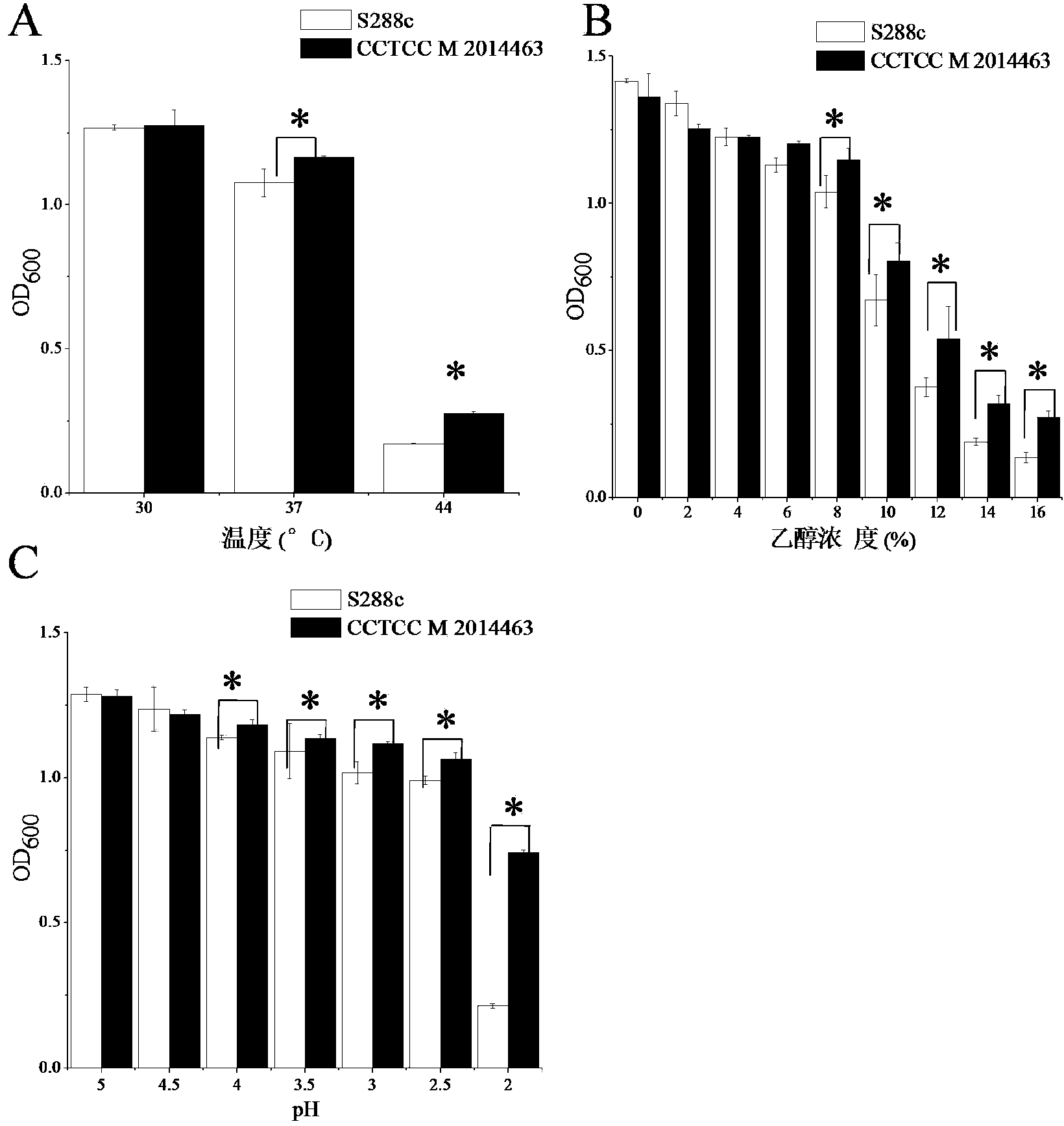

[0044] Example 2 Saccharomyces cerevisiae CCTCC NO: M 2014463 ability to tolerate stress conditions

[0045] Comparison of stress tolerance between Saccharomyces cerevisiae CCTCC NO:M 2014463 and Saccharomyces cerevisiae S288C, a type strain of Saccharomyces cerevisiae.

[0046] Temperature tolerance: After the strain is activated, according to the inoculum size of 2%, the OD is determined after static culture in YPD liquid medium at 30°C, 37°C, and 44°C for 48 hours 600 .

[0047] Ethanol tolerance: After the strain is activated, according to the inoculation amount of 2%, the YPD liquid medium is used as the basal medium, and 0%, 2%, 4%, 6%, 8%, 10%, 12%, 14% are added respectively , 16% (v / v) at 30°C for 48 hours and then measure OD600.

[0048] Acid tolerance: After the strain is activated, according to the inoculum size of 2%, the YPD liquid medium is used as the basal medium, and the pH is adjusted to 5, 4.5, 4, 3.5, 3, 2.5, 2 with lactic acid and cultured at 30°C for 4...

Embodiment 3

[0050] Example 3 Saccharomyces cerevisiae CCTCC NO: M 2014463 Flavor Metabolism Ability

[0051] Saccharomyces cerevisiae CCTCC NO:M 2014463 can metabolize various flavor substances. It was inoculated in sorghum juice medium, and fermented plugs were prepared for static culture at 30°C, fermented for 5 days, and the flavor metabolites in the fermented liquid were detected by GC-MS.

[0052] The result is as Figure 4 As shown, Saccharomyces cerevisiae CCTCC NO:M 2014463 can metabolize: acids (caproic acid, caprylic acid, nonanoic acid, 9-decenoic acid), alcohols (ethanol, isobutanol, isoamyl alcohol, butanol, hexanol, -2-nonen-1-ol, 3-methyl-1-hexanol, 1-octanol, nonanol, 3-methyl-1-hexanol, phenylethyl alcohol, lauryl alcohol, trans-nerolidol alcohol, farnesol), esters (ethyl acetate, isopentyl acetate, ethyl caproate, ethyl 4-hexenoate, ethyl caprylate, ethyl caprate, 2-phenylethyl acetate, 2-phenylethyl phenylacetate, isohexyl-2-phenylethyl ester, ethyl 2,4-hexadienoate)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com