Iron ion loaded activated carbon fiber composite cathode, preparation method and application thereof

An activated carbon fiber, composite cathode technology, applied in chemical instruments and methods, special compound water treatment, textile industry wastewater treatment and other directions, can solve the problems of complex process, secondary pollution, etc. The effect of reducing adverse side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

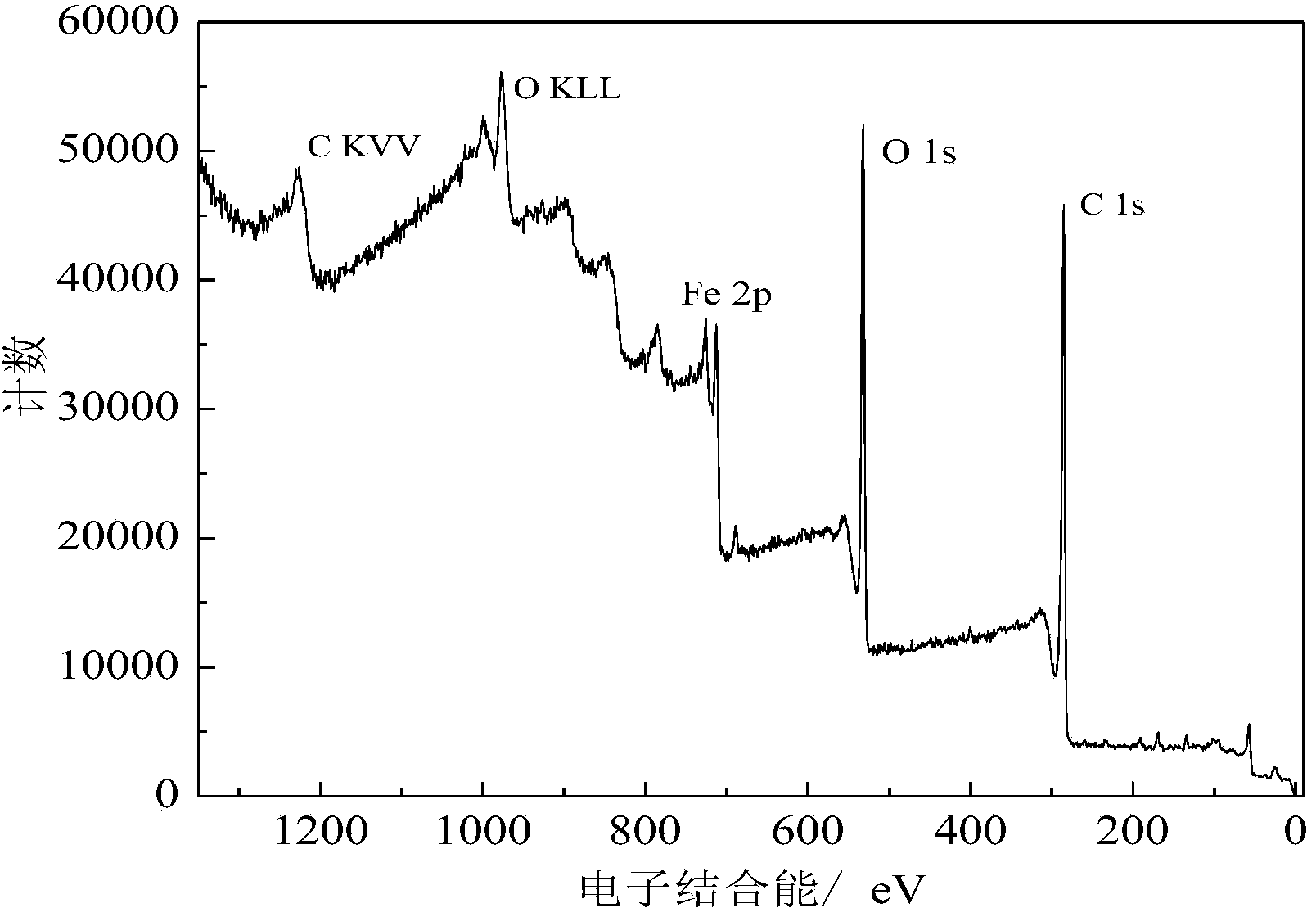

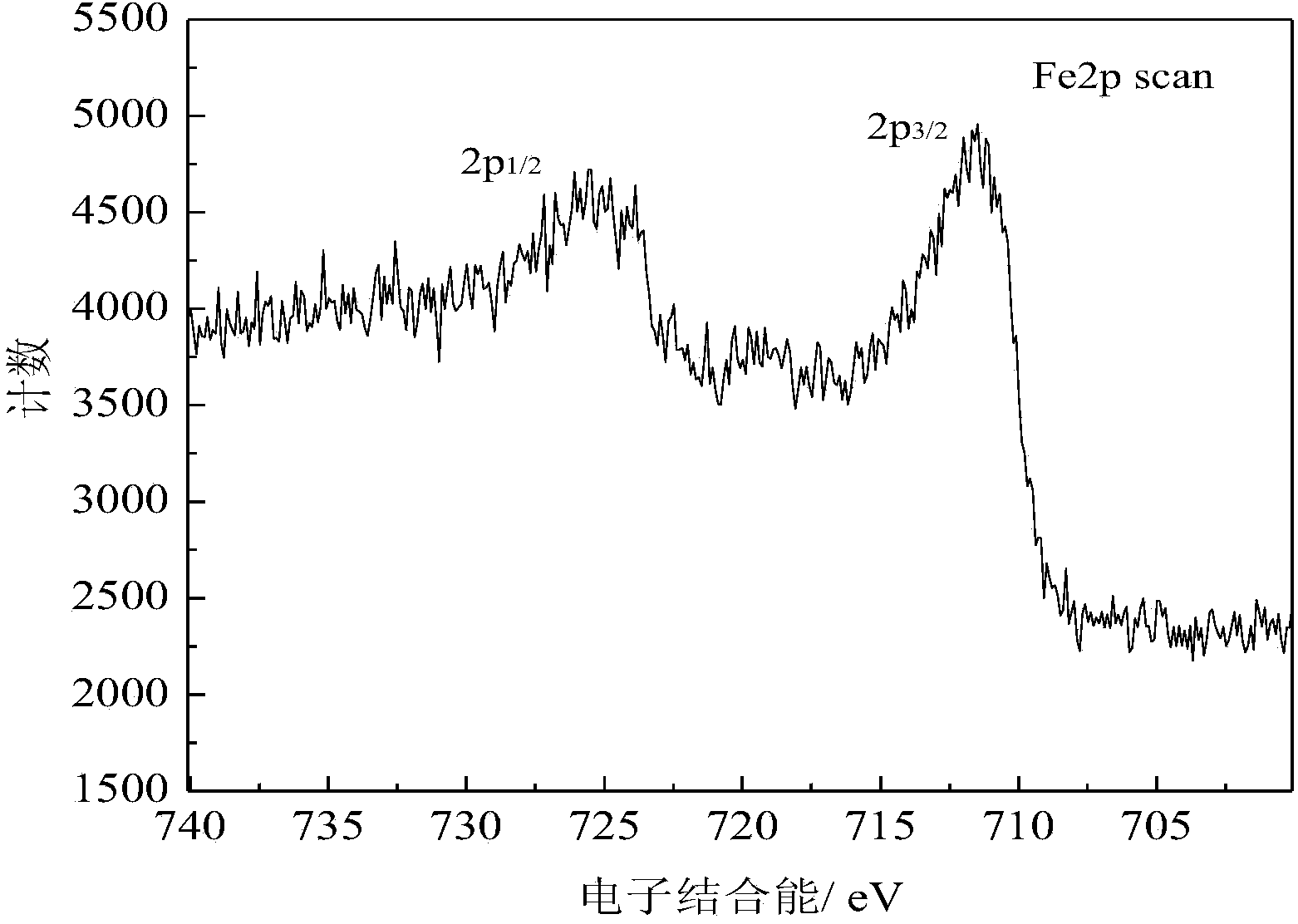

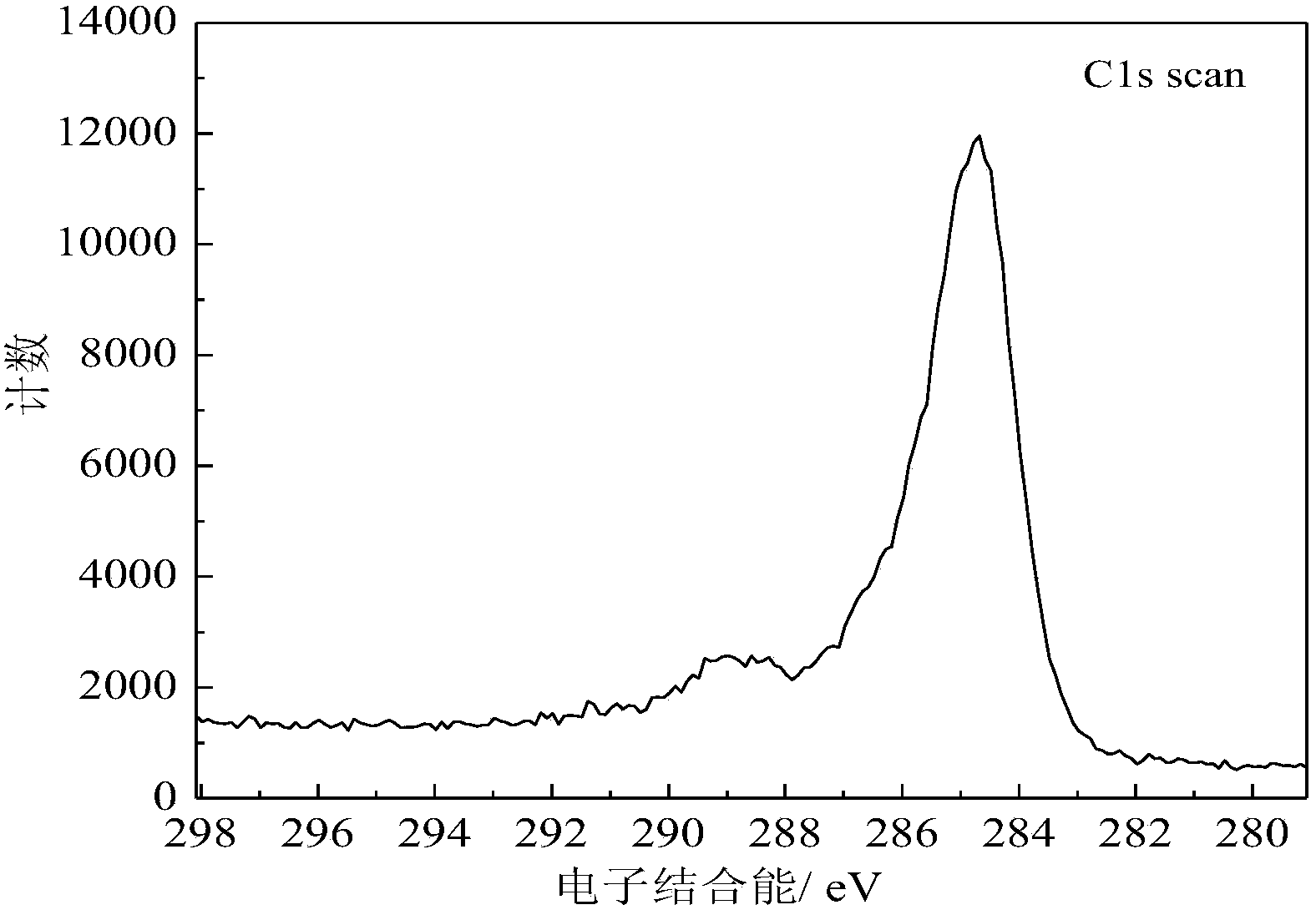

[0070] Example 1: Preparation of Fe / ACF composite cathode by inner layer adsorption method and XPS characterization

[0071] Step 1, the acidification of ACF: with 0.5g ACF (specific surface area 1500m 2 g -1 ) into 100mL 40% (mass concentration) H 2 SO 4 solution, in a constant temperature shaker at 30°C at 30r·min -1 Take it out after oscillating at a rotating speed of 24 hours, wash it with deionized water 2 to 3 times, and dry it at 100°C for 1 hour;

[0072] Step 2, ACF loaded with iron ions: place the acidified ACF in step 1 in 0.66mol L -1 FeSO 4 solution, in a constant temperature shaker at 30°C at 30r·min -1 Take it out after oscillating at a rotating speed of 24 hours, wash it with deionized water until neutral, and dry it at 100°C for 1 hour;

[0073] Fix the Fe / ACF obtained in step 2 on a polytetrafluoroethylene tube with holes to obtain the Fe / ACF composite cathode.

[0074] The elemental analysis of Fe / ACF surface was carried out by X-photoelectron spectr...

Embodiment 2

[0076] Embodiment 2: Precipitation method prepares Fe / ACF composite cathode and XPS characterization

[0077] Step 1, the pretreatment of ACF: with 0.4g ACF (specific surface area 1500m 2 g -1 ), cut into 7cm×9cm slices, immersed in 5% hydrochloric acid, heated and boiled for 1 hour to remove possible impurities and inorganic ions, rinsed with deionized water; immersed in 5% sodium hydroxide, heated and boiled for 1 hour, and then Boil in deionized water for 1 hour, let stand overnight, wash with deionized water until neutral, and dry at 100°C for 24 hours;

[0078] Step 2, ACF loaded with iron ions: fix the acidified ACF in step 1 on the support, and the immersion concentration is 0.18mol L -1 FeSO 4 To the solution, add 5mol·L dropwise at 70°C -1 Sodium hydroxide solution 50mL, and stirred loading reaction for 5 hours. After the reaction was completed, rinse and soak the loaded surface with deionized water until the deionized water was clear, and dry at 100°C for 1 h. ...

Embodiment 3

[0082] Embodiment 3: capture of hydroxyl radical (OH) in the reaction

[0083] In a 200mL beaker, add 0.05mol·L -1 Na 2 SO 4 and 10mmol·L -1 Coumarin solution, adjust the pH of the solution to 3.0, the potential to -1.0V, and the oxygen flow to 2.0L min -1 , the Fe / ACF composite cathode prepared in Example 1 is used as the working electrode, the spiral platinum wire is the auxiliary electrode, and the saturated calomel electrode is the reference electrode, and the three electrodes are put into the above solution; Sampling in the middle, and sampling in the solution every 10 minutes for the next 30 minutes, using a fluorescence spectrometer to measure the fluorescence intensity of the sample at an excitation wavelength of 332nm and an emission wavelength of 460nm, because coumarin can react with OH to form a stable and fluorescent 7 -Hydroxycoumarin, so measuring the fluorescence intensity of 7-hydroxycoumarin can reflect the amount of OH produced by the system.

[0084] D...

PUM

| Property | Measurement | Unit |

|---|---|---|

| decolorization rate | aaaaa | aaaaa |

| decolorization rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com