Preparation method of high-oxide content flake-like contact material

A contact material and oxide technology, which is applied in the field of preparation of high oxide content sheet contact materials, can solve the contact failure, reduce the bonding strength of the welding silver layer and the silver oxide, and separate the silver layer and the silver oxide. or shedding, etc., to achieve high bonding strength, suitable for mass production, and solve the effect of low bonding strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

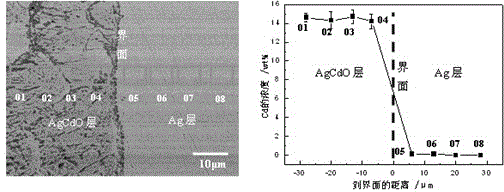

Embodiment 1

[0032] Weigh 16.2kg of silver ingots, melt them in an intermediate frequency induction furnace, add 3.09kg of cadmium ingots, 0.66kg of oxygen-free copper, 0.04kg of nickel flakes and 0.01kg of aluminum-zinc intermediate alloys in turn, and cast them into ingots after melting completely evenly. ℃ for 4 hours in a furnace, extruded into plates, welded with silver plates, put them together in a medium frequency induction heating furnace, heated for 5 minutes to 700°C, hot rolled into silver-coated plates, punched after multiple passes of cold rolling 1.50mm thick sheet contact, then anneal the contact at 700°C for 2 hours in a nitrogen protective atmosphere, then take the contact out and put it in an internal oxidation furnace for internal oxidation treatment, the internal oxidation temperature is 750°C, and the oxygen pressure is 0.8 MPa, the time is 65 hours, and finally the finished product is obtained after grinding, polishing, cleaning and drying.

[0033] The finished silv...

Embodiment 2

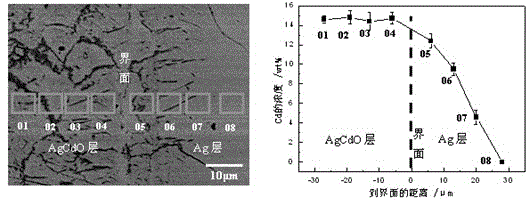

[0036] Weigh 15.95kg of silver ingots, melt them in an intermediate frequency induction furnace, add 3.60kg of cadmium ingots, 0.41kg of oxygen-free copper, 0.03kg of nickel flakes, and 0.01kg of aluminum and bismuth ingots in turn, and cast them into ingots after melting evenly. Heat in an induction furnace for 10 minutes to 770°C, extrude into a plate, heat the plate in an intermediate frequency induction furnace for 5 minutes to 550°C after riveting the silver plate, and hot-roll it into a silver-coated plate, which is cold-rolled and punched for multiple passes Form a 0.6mm thick sheet contact, then anneal the contact at 500°C for 8 hours in an argon protective atmosphere, and then put it into an internal oxidation furnace for internal oxidation treatment, the internal oxidation temperature is 800°C, and the oxygen pressure is 0.5MPa , the time is 15 hours, and finally the finished product is obtained after grinding, polishing, cleaning and drying.

[0037] The finished si...

Embodiment 3

[0040]Weigh 17.24kg of silver ingots, melt them in a medium frequency induction furnace, add 2.04kg of tin ingots, 0.68kg of indium ingots, 0.03kg of nickel flakes and 0.01kg of oxygen-free copper and bismuth ingots in turn, and cast them into ingots after melting evenly. Insulate in a tube furnace at 650°C for 4 hours, extrude into a plate, weld the plate with silver plate, heat it in a furnace at 600°C for 2 hours, and hot-roll it into a silver-coated plate. The plate is cold-rolled multiple times and punched to 3.0mm Thick sheet contacts, then anneal the contacts at 800°C for 1 hour in a nitrogen protective atmosphere, and then put them into an internal oxidation furnace for internal oxidation treatment. The internal oxidation temperature is 650°C, the oxygen pressure is 1.2MPa, and the time is 150 Hours, and finally the finished product is obtained after grinding, polishing, cleaning and drying.

[0041] The finished silver tin oxide and indium oxide electrical contact mat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Resistivity | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com