Preparation method of super absorbent resin containing humic acid

A technology of superabsorbent resin and humic acid, which is applied in fermentation and other directions, can solve problems such as waste and lignin destruction, and achieve the effects of fast water absorption rate, good mechanical strength and high economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

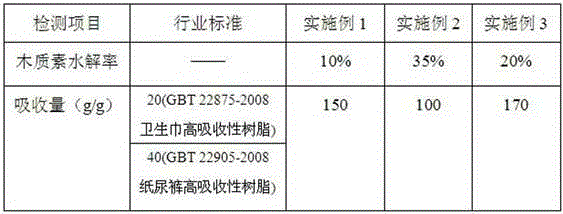

Examples

Embodiment 1

[0018] A kind of preparation method of superabsorbent resin containing humic acid, it comprises the following steps:

[0019] A. soak 100Kg bagasse with deionized water to remove residual sugar, then dry at 60°C, and pulverize the bagasse with a pulverizer, and pass through a 20-mesh sieve to obtain bagasse powder;

[0020] B. Put 5×10 7 U lignin peroxidase and 1L hydrogen peroxide were added to the bagasse powder, then the pH value was adjusted to 3.0, and the enzymolysis was carried out at a temperature of 30°C for 48h;

[0021] C. After the enzymolysis described in step B is completed, filter the lignin hydrolyzate and set it aside; at the same time, mix the remaining residue with 15 times the amount of water, and gelatinize at 30°C for 55 minutes;

[0022] D. After the gelatinization in step C is completed, add the lignin hydrolyzate obtained in step C, mix well, and then add 3Kg potassium persulfate, 3Kg sodium thiosulfate, 0.8Kg N, N'-methylenebisacrylamide and 250L ...

Embodiment 2

[0025] A kind of preparation method of superabsorbent resin containing humic acid, it comprises the following steps:

[0026] A. Soak 100Kg bagasse with clear water to remove residual sugar, then dry at 80°C, and pulverize the bagasse with a pulverizer, and pass through a 40-mesh sieve to obtain bagasse powder;

[0027] B. Divide 2×10 8 U manganese peroxidase and 5L hydrogen peroxide were added to the bagasse powder, then the pH value was adjusted to 5.0, and the enzymolysis was carried out at a temperature of 45°C for 36 hours;

[0028] C. After the enzymolysis described in step B is completed, filter the lignin hydrolyzate and set it aside; at the same time, mix the remaining residue with 20 times the amount of water, and gelatinize at 60°C for 30 minutes;

[0029] D. Add the lignin hydrolyzate obtained in step C after the gelatinization in step C is completed, mix well, and then add 3.5Kg potassium persulfate, 3.5Kg sodium thiosulfate, 1KgN,N'-methylenebispropylene Mix am...

Embodiment 3

[0032] A kind of preparation method of superabsorbent resin containing humic acid, it comprises the following steps:

[0033] A. soak 100Kg bagasse with deionized water to remove residual sugar, then dry at 100°C, and pulverize the bagasse with a pulverizer, and pass through a 60-mesh sieve to obtain bagasse powder;

[0034] B. Divide 3×10 8 Laccase and 10L hydrogen peroxide were added to the bagasse powder, then the pH value was adjusted to 7.0, and the enzymolysis was carried out at a temperature of 60°C for 10 hours;

[0035] C. After the enzymolysis described in step B is completed, filter the lignin hydrolyzate and set aside; at the same time, mix the remaining residue with 25 times the amount of water, and gelatinize at 80°C for 15 minutes;

[0036] D. Add the lignin hydrolyzate obtained in step C after the gelatinization in step C is completed, mix well, and then add 4Kg potassium persulfate, 3.5Kg sodium thiosulfate, 1.5Kg N,N'-methylenebispropylene Mix amide and 800...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com