Polyimide-based composite film with optical limiting performance

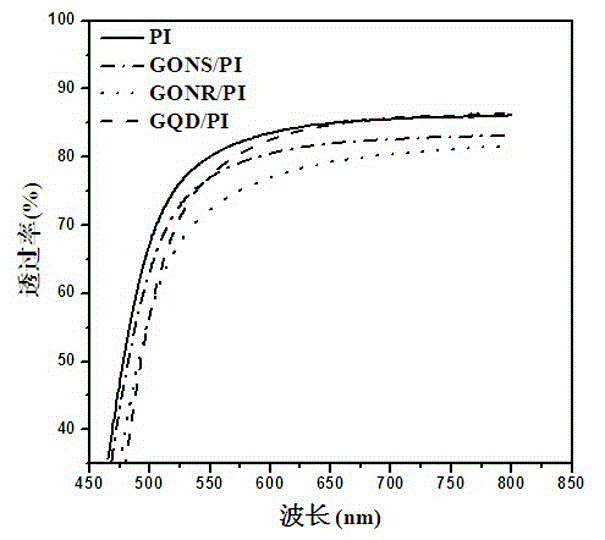

A polyimide-based, composite film technology, applied in the field of laser protection, can solve the problems of difficult liquid phase materials and lack of practical value, and achieve the effect of good light transmission

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Preparation of graphene oxide nanosheets / polyimide composite films. Specific steps are as follows:

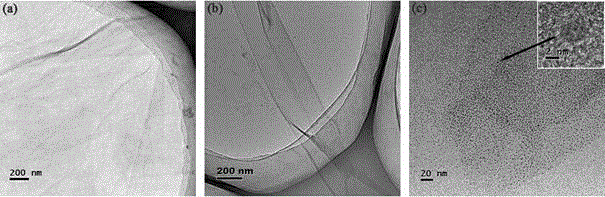

[0027] (1) Preparation of graphene oxide nanosheets

[0028] Using improved Hummers method, using graphite as raw material, concentrated H 2 SO 4 as solvent, KMnO 4 Fabrication of graphene oxide nanosheets (GONSs) for oxidants. The basic process is: 11.5 mL concentrated H 2 SO 4 Mix with 0.5 g graphite and stir well, then slowly add 1.5 g KMnO 4 , continued to react for 4 h, and the solution was purple-green. After the reaction was completed, 22 mL of deionized water was slowly added dropwise to the mixture (keep the temperature below 100 °C). Add 5% hydrogen peroxide dropwise until the color of the mixture turns golden yellow. The reacted solution was filtered and washed with 5% HCL solution and washed repeatedly with deionized water until the filtrate was neutral (pH≈7) and free of SO 4 2- . The obtained solid was redispersed in ultrapure water, and after u...

Embodiment 2

[0038] Preparation of graphene oxide nanoribbons / polyimide composite films. Specific steps are as follows:

[0039] (1) Preparation of graphene oxide nanoribbons

[0040] In 36 mL of concentrated H 2 SO 4 Add 0.15 g MWCNTs to the solution, stir magnetically for 1-2 h, then add 4 mL H 3 PO 4 , and continue stirring for 15 min. Add 0.75 g KMnO 4 Then, it was transferred to an oil bath at 65 °C and stirred for 2 h. After the reaction was completed and cooled to room temperature, 100 mL of ice water (containing 5 mL of 30% H 2 o 2 ), let stand for 14 h.

[0041]After standing still, pour off the supernatant, filter the remaining solution with a 220 μm microporous membrane, and wash twice with 6 mL of 20% HCl. The solid obtained by suction filtration was redispersed in 60 mL of ultrapure water, stirred for 2 h, and then ultrasonicated to obtain a uniformly dispersed solution, which was added to 40 mL of 30% HCl and allowed to stand for 14 h.

[0042] Suction filter with ...

Embodiment 3

[0052] The preparation of graphene quantum dot / polyimide composite film, concrete steps are as follows:

[0053] (1) Preparation of graphene quantum dots

[0054] Reduction treatment of GONSs: put GONSs into a square crucible and put them in a vacuum tube furnace, and pass N 2 , control the heating rate to 5 ℃ min -1 , heated to 300°C in N 2 The reduced graphene (GNSs) was obtained by incubating in the atmosphere for 2 h.

[0055] Sonication: Dissolve 0.05 g GNSs with 10 mL concentrated H 2 SO 4 and 30 mL concentrated HNO 3 Mix and sonicate for 15-20 h.

[0056] Hydrothermal reaction: Add 250 mL of ultrapure water to the above mixture for dilution, filter with suction through a 220 μm microporous membrane, and dry the obtained solid. Weighed 0.2 g of the obtained solid and mixed it with 40 mL of deionized water, then ultrasonicated until uniformly dispersed, and adjusted its pH to 8 with NaOH. The resulting mixture was placed in a 50 mL polytetrafluoroethylene hydrothe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Film thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com