A stirred bioreactor for sonic cultivation of microorganisms

A technology of bioreactors and microorganisms, which is applied in the direction of specific-purpose bioreactor/fermenter, combination of bioreactor/fermenter, method for stimulating microbial growth by stress, etc. Stirred bioreactors and other issues to achieve the effects of accelerated metabolic activities, increased yield, and good cultivation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] Example 1 Application of Stirred Bioreactor for Microorganism Acoustic Cultivation in Increasing the Production of Microbial Metabolites and Comparison of Production Results

[0028] Microbial material: liquid strain of Streptomyces natalis

[0029] Medium: 1. Plate and slant medium g / L: glucose 10, wort juice 3, yeast extract 3, peptone 5, agar 20, pH7.0~pH7.3; 2. Seed medium g / L: glucose 20 , soybean peptone 10, yeast extract 6, sodium chloride 10, pH7.3; 3. Fermentation medium g / L: soybean cake powder 40, glucose 20, soluble starch 40, yeast extract 7, pH7.0.

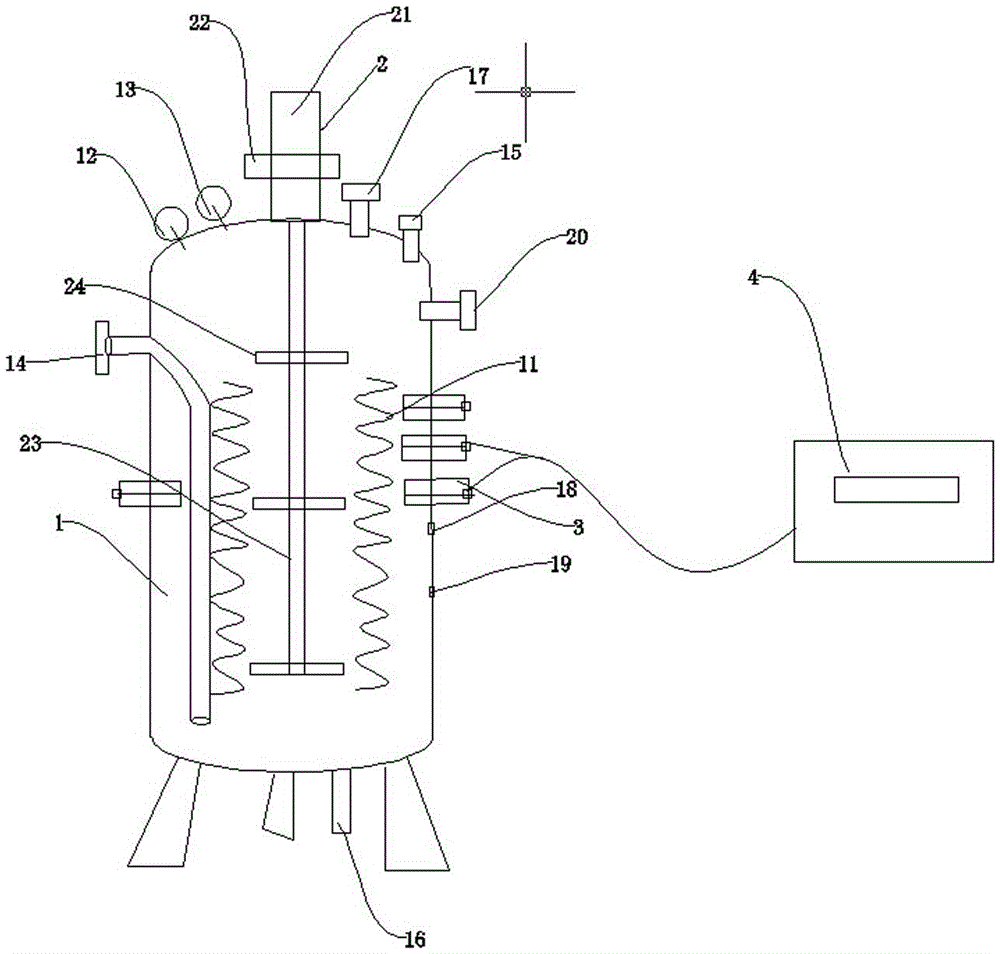

[0030]Operation steps: Divide the microorganism Streptomyces natalis liquid bacteria into two groups, the first group adopts the traditional culture method to cultivate; the second group adopts the stirred bioreactor for the sonic culture of microorganisms of the present invention to cultivate, the specific operation The method is as follows: first pass steam through the air inlet 14 to sterilize the empty ta...

Embodiment 2

[0034] Example 2, the application of the stirred bioreactor for the sonic culture of microorganisms in accelerating the growth rate of microorganisms and the comparison of the cultivation effect

[0035] Microbial material: Bacillus subtilis strain

[0036] Medium: cornstarch 15g / L, bean cake powder 10g / L, NH 42 SO 4 6g / L, corn steep liquor 3g / L, bran 5g / L, MgSO 4 1g / L, K 2 HPO 4 2g / L,MnSO 4 0.05g / L, CaCO 3 0.4g / L, pH7.0, 25% dissolved oxygen level, 42°C, 3 days.

[0037] Set a group of Bacillus subtilis cultured according to the conventional culture method; the operation of the stirred bioreactor adopting the microbial acoustic wave culture of the present invention is: first pass through the air inlet 14, feed steam into the empty tank of the bioreactor to sterilize. Then the sterilized culture medium is injected into the tank body 1 through the feed port 20 . When the temperature drops to the inoculation temperature, the liquid strain of Bacillus subtilis is inserted...

example 3

[0041] Example 3: Application of a stirred bioreactor for microbial sonic culture in increasing microbial oil production and comparison of production results

[0042] Microbial material: Rhodotorula viscosus CICC31596 strain

[0043] Medium: glucose 80g / L, ammonium sulfate 1.11g / L, potassium dihydrogen phosphate 2.5g / L, peptone 1.8g / L initial, pH 5.8, 40mL fermentation broth in 250mL Erlenmeyer flask.

[0044] The microorganism Rhodotorula viscosus CICC31596 bacterium is divided into two groups, and the first group adopts the traditional culture method to cultivate; the second group adopts the stirring type bioreactor of the present invention for microbial sonic cultivation to cultivate, first through the air inlet 13, Sterilize the empty tanks of the bioreactor by passing steam. Then the sterilized culture medium is injected into the tank body 1 through the feed port 16 . When the temperature drops to the inoculation temperature, the liquid strain of Bacillus coagulans is i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com