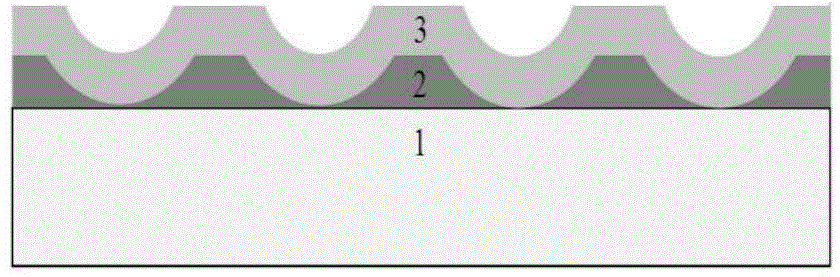

ZnO/NiO heterostructure orderly multi-hole thin film and manufacturing method thereof

A porous film and heterostructure technology, applied in the semiconductor field, can solve the problems of semiconductor devices that have not been reported, and achieve the effect of improving the overall performance, good resistive characteristics, and obvious rectification characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

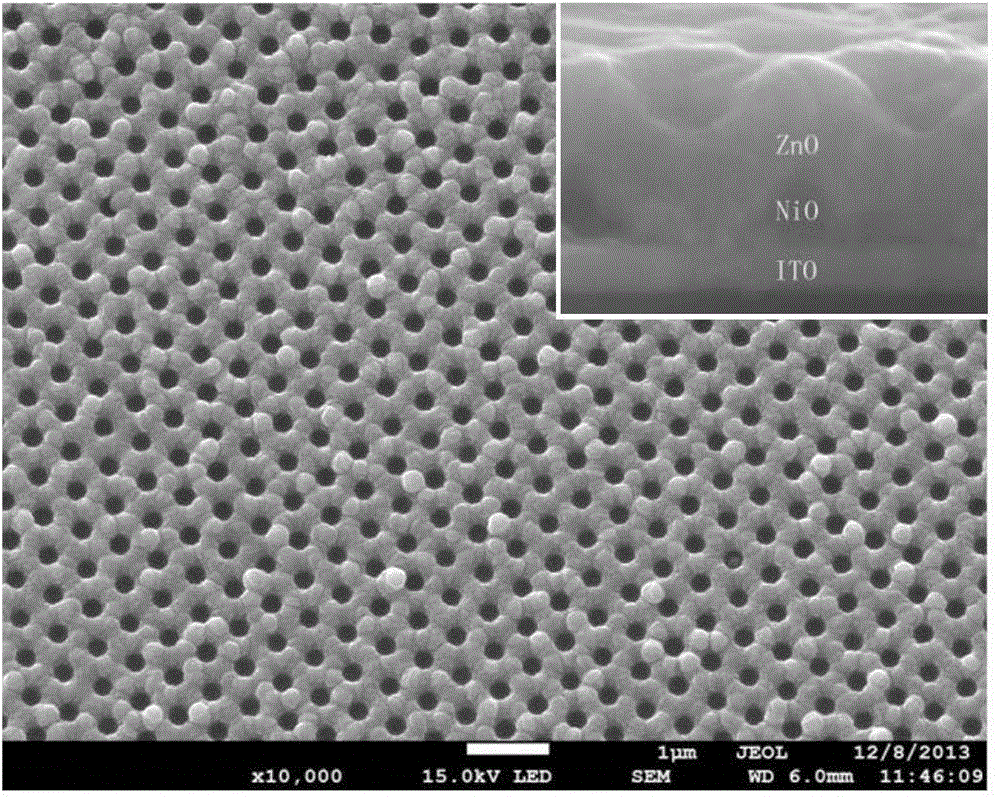

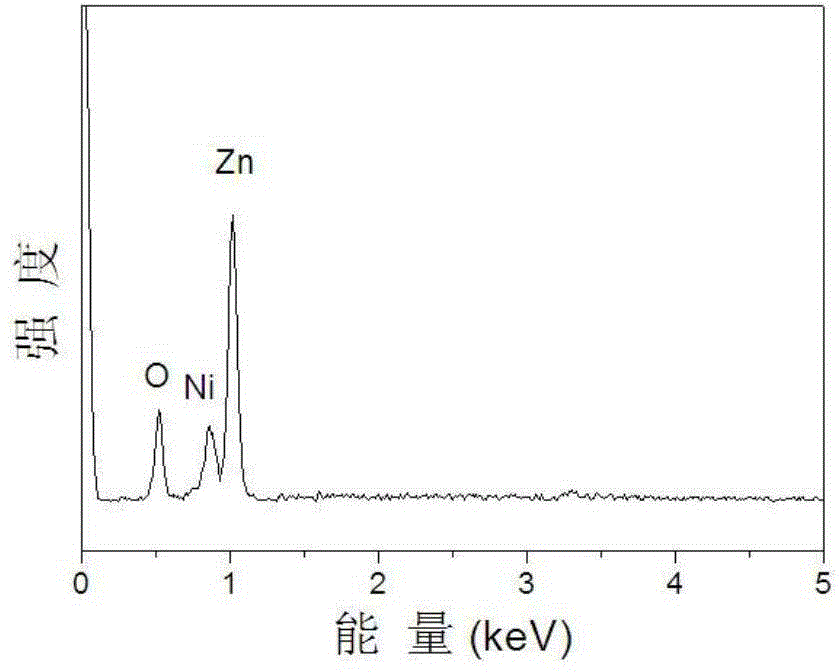

[0027] Example 1 Preparation of ZnO / NiO Heterostructure Ordered Porous Film

[0028] Step 1, first place the single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 500nm on the conductive glass, and then place the conductive substrate with the single-layer colloidal crystal template on it in the nickel electrolyte to It is the working electrode, graphite is the counter electrode, and the current density is 1.0mA / cm 2 Electrodeposition by the two-electrode method was carried out for 5 minutes to obtain an ordered porous film of metallic nickel;

[0029] Step 2, place the conductive substrate grown on the ordered porous film of metallic nickel in a high-temperature tube furnace for thermal oxidation treatment, during which the high-purity O 2 The flow rate is 30sccm, the heating rate is 2°C / min, and the temperature is raised to 500°C. After maintaining the temperature for 3 hours, it is naturally cooled to room temperature. The coll...

Embodiment 2

[0034] Example 2 Preparation of ZnO / NiO Heterostructure Ordered Porous Film

[0035] Step 1, first place a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 500nm on a conductive glass substrate, and then place the conductive substrate with a single-layer colloidal crystal template on it in a nickel electrolyte , using it as the working electrode and graphite as the counter electrode, at a current density of 1.5mA / cm 2 The ordered porous film of metallic nickel was obtained by electrodepositing for 4 minutes by the two-electrode method;

[0036] Step 2, place the conductive substrate grown on the ordered porous film of metallic nickel in a high-temperature tube furnace for thermal oxidation treatment, during which the high-purity O 2 The flow rate is 40sccm, the heating rate is 4°C / min, and the temperature is raised to 500°C. After maintaining the temperature for 4 hours, it is naturally cooled to room temperature. The colloi...

Embodiment 3

[0039] Example 3 Preparation of ZnO / NiO Heterostructure Ordered Porous Film

[0040] Step 1, first place a single-layer colloidal crystal template composed of polystyrene colloidal spheres with a diameter of 500nm on a silicon wafer coated with an ITO conductive layer, and then place a conductive substrate with a single-layer colloidal crystal template on it. In the nickel electrolyte, use it as the working electrode and graphite as the counter electrode, at a current density of 2.0mA / cm 2 The ordered porous film of metallic nickel was obtained by electrodepositing for 4 minutes by the two-electrode method;

[0041] Step 2, place the conductive substrate grown on the ordered porous film of metallic nickel in a high-temperature tube furnace for thermal oxidation treatment, during which the high-purity O 2 The flow rate is 40sccm, the heating rate is 3°C / min, and the temperature is raised to 400°C. After maintaining the temperature for 3 hours, it is naturally cooled to room te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com