Nitrogen-doped nanocarbon coated/oxidized modified graphite composite material and preparation method thereof

A nitrogen-doped nano-carbon, oxidation modification technology, applied in electrical components, battery electrodes, circuits, etc., can solve problems such as battery safety hazards and environmental pollution, and achieve high current performance improvement, good conductivity, and high current performance. obvious effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

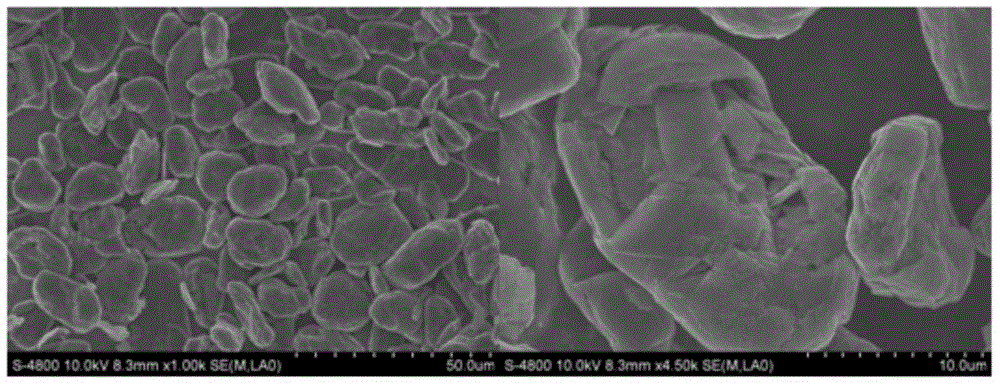

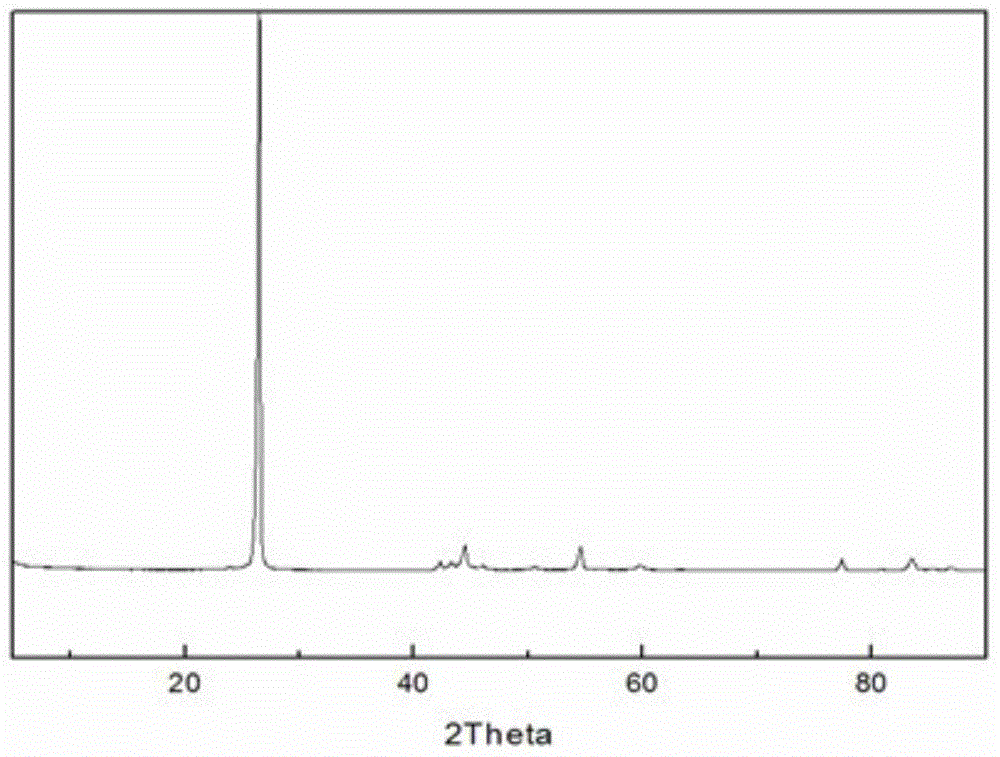

[0037] 24g graphite raw material (particle size D 50 = 16.1 μm) (Shanghai Shanshan Technology Co., Ltd., natural graphite) was placed in the reactor, 9.6 g of hydrogen peroxide with a concentration of 30 wt% was added, and 20 ml of glacial acetic acid was added (hydrogen peroxide was used as an oxidant, and glacial acetic acid was conducive to the increase of the graphite layer spacing. ), mixed and stirred evenly, reacted in an oven at 95 °C for 12 h, taken out and cooled naturally, and dried the sample in an oven at 105 °C. The dried sample was put into a quartz tube furnace with nitrogen gas, and 30 ml of diethylamine was introduced at the same time, and the temperature was raised to 1000 °C at 20 °C / min, kept for 2 hours, and naturally cooled to obtain a modified natural graphite sample.

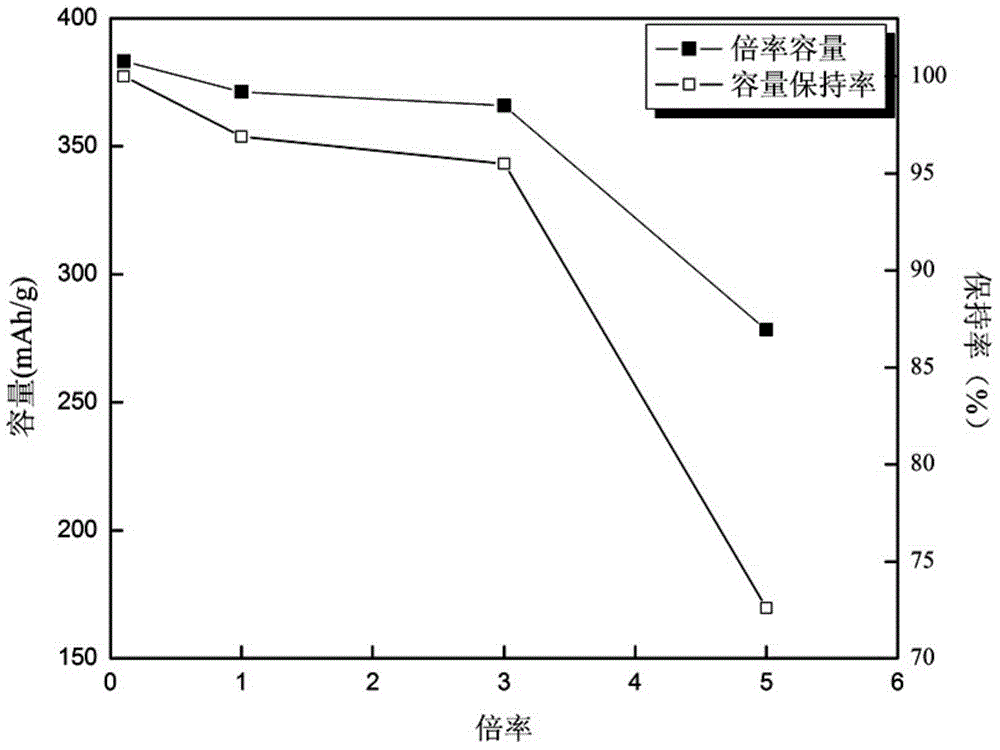

[0038] The prepared modified sample was taken out and used as the negative electrode material. Lithium sheet was used as the positive electrode material, and 1 mol / L LiPFB was used. 6B ...

Embodiment 2

[0043] In the present embodiment, the amount of hydrogen peroxide added is 14.4g, except that, other processes and conditions are consistent with embodiment 1. The average particle diameter D of the modified graphite obtained in the present embodiment 50 It is basically the same as Example 1 (16.2 μm). At 0.1C, its first charge capacity is 383.1mAh / g, the first discharge capacity is 462.2mAh / g, and the first Coulombic efficiency is 89.9%. Under the current density of 3C, the chargeable gram capacity is 336.3mAh / g, and the capacity retention rate is 87.8%. At a current density of 1C, after 20 charge-discharge cycles, the charging capacity is 303.9mAh / g, and the capacity retention rate is 84.2%.

Embodiment 3

[0045] In this embodiment, the added oxidizing agent is concentrated phosphoric acid, and the added amount is 2.4 g. Other than that, other processes and conditions were consistent with Example 1. The average particle diameter D of the modified graphite obtained in the present embodiment 50 It is 17.3 μm, larger than the particle size of the sample in Example 1. At 0.1C, its initial charge capacity is 350mAh / g, its initial discharge capacity is 395.9mAh / g, and its initial Coulombic efficiency is 88.4%. Under the current density of 3C, the chargeable gram capacity is 341.0mAh / g, and the capacity retention rate is 97.4%. At a current density of 1C, after 20 charge-discharge cycles, the charging capacity is 291.4mAh / g, and the capacity retention rate is 83.3%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com