Flocculation treatment agent

一种处理剂、乳剂的技术,应用在凝集处理剂领域,达到稳定性高、提高聚合度的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment )

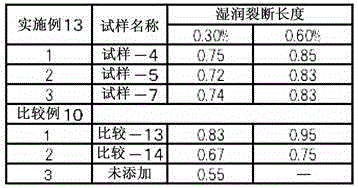

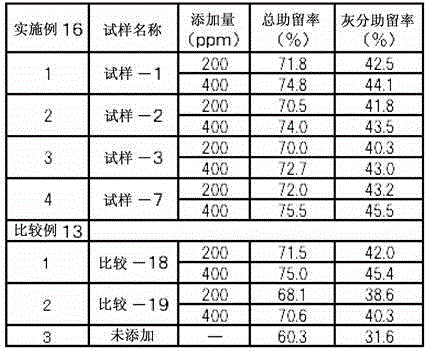

[0069] (Examples) Hereinafter, although an Example demonstrates this invention in detail, this invention is not restricted by the following Example in the range which does not exceed the summary.

[0070] (Manufacture of N-vinylcarboxamide polymer water-in-oil emulsion 1)

[0071]In a four-necked 500mL separable flask equipped with a stirrer, a reflux condenser, a thermometer, and a nitrogen gas introduction tube, 185.6 g of isoparaffins with a boiling point of 190° C. to 230° C. were charged with a nonionic active agent HypermerH1084 (Croda Japan KK. system) 13.0g and dissolve it. Separately, 166.4 g of N-vinylformamide (purity: 99.8% by mass), 0.16 g of sodium formate, and 134.9 g of ion-exchanged water were collected and added. The oil and the aqueous solution were mixed and emulsified with a homomixer at 8000 rpm for 2 minutes. The obtained emulsion was stirred and the temperature of the monomer solution was kept in the range of 20~25°C. After nitrogen replacement for 30...

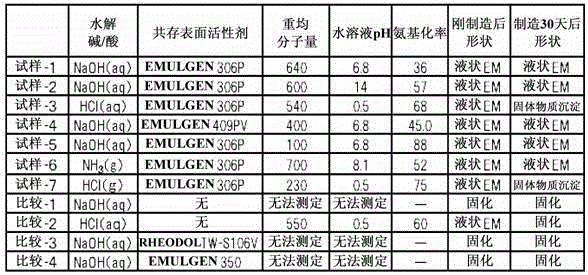

Embodiment 1

[0075] Take 252.6 g of PNVF-1 and 12.6 g of polyoxyethylene stearyl ether (EMULGEN 306P (HLB9.4) manufactured by Kao Corporation) into a four-necked 500 mL separable flask equipped with a stirrer, a reflux condenser, a thermometer, and a dropping funnel ), stirred at 50°C to fully dissolve and mix. After confirming the dissolution, the temperature was raised to 80°C, 12.6 g of a 20% by mass aqueous solution of hydroxylamine hydrochloride was added, and 98.7 g of an aqueous sodium hydroxide solution (purity: 48% by mass) was added dropwise over 1 minute using a dropping funnel, and 80°C was carried out at 80°C. hours of hydrolysis. After the completion of the hydrolysis reaction, 123.5 g of hydrochloric acid aqueous solution (purity: 35% by mass) was added and neutralized using the dropping funnel. After neutralization, 20 g of polyoxyethylene alkyl ether (HLB13.3) was added to obtain a water-in-oil emulsion of polyvinylamine. This is referred to as sample-1, and the pH at a ...

Embodiment 2

[0077] A water-in-oil emulsion of polyvinylamine was obtained in the same manner as in Example 1, except that neutralization was not performed with an aqueous hydrochloric acid solution. This is referred to as Sample-2, and the intrinsic viscosity at 25°C in an aqueous NaCl solution with a concentration of 1 mol / L, the pH at a concentration of 1% by mass, and the properties immediately after manufacture and 30 days after manufacture (storage at 25°C) are shown. In Table-1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

| molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com