A method of joint treatment of municipal sludge using energy grass and anaerobic fermentation technology

A municipal sludge and anaerobic fermentation technology, applied in the field of waste recycling, can solve the problems of reducing heavy metal content, high content of inorganic substances such as mud and sand, and low gas production, so as to reduce heavy metal content, realize cascade utilization, and improve utilization efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Example 1: A method for joint treatment of municipal sludge using giant fungus grass and anaerobic fermentation technology

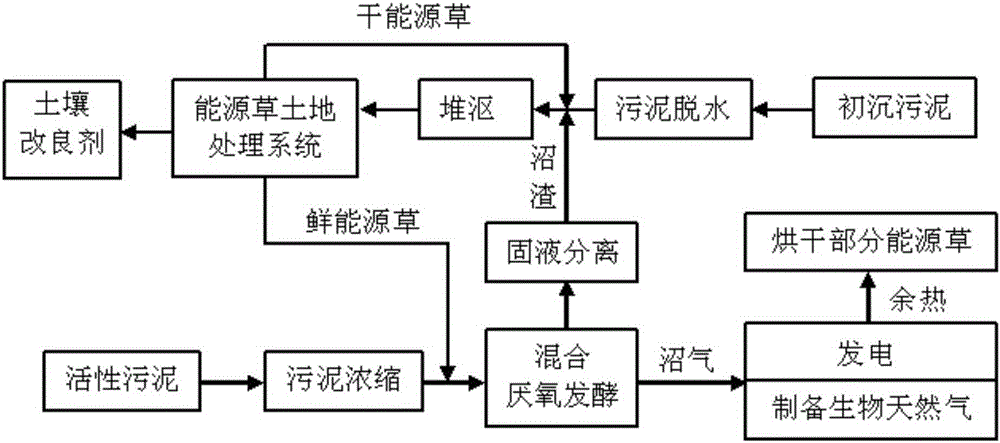

[0030] like figure 1 As shown, the method for joint treatment of municipal sludge utilizing giant fungus grass and anaerobic fermentation technology comprises the following steps:

[0031] a. After concentrating the activated sludge in the municipal sludge to a water content of 97% to 98%, it is mixed with fresh giant fungus at a mass ratio of 1:1 to 2:1 for medium temperature anaerobic fermentation, and the generated biogas is used for Power generation; solid-liquid separation of the fermentation residue to obtain biogas residue and biogas slurry; the biogas slurry is returned to the sewage plant for further treatment; the waste heat generated by the biogas power generation is used to dry giant fungus grass to obtain a moisture content of 20% Dried giant fungus grass;

[0032] b. Dewater the primary sludge in the municipal sludge to a moisture ...

Embodiment 2

[0034] Embodiment 2: Utilize switchgrass and the method for anaerobic fermentation technology joint treatment municipal sludge

[0035] a. After concentrating the activated sludge in the municipal sludge to a moisture content of 97% to 98%, it is mixed with fresh switchgrass at a mass ratio of 1:1 to 2:1 for mesophilic anaerobic fermentation, and the generated biogas is used for power generation; Solid-liquid separation of the fermentation residue to obtain biogas residue and biogas slurry; the biogas slurry is returned to the sewage plant for further processing; the waste heat generated by the biogas power generation is used to dry switchgrass to obtain dry switchgrass with a moisture content of 30%;

[0036] b. Dewater the primary sludge in the municipal sludge to a moisture content of 80% to 85%, mix it with the biogas residue obtained in step a at a mass ratio of 2:1 to 3:1, and add the moisture content obtained in step a Adjust the moisture content to 60% for 30% dry swit...

Embodiment 3

[0037]Embodiment 3: Utilize the method of elephant grass and anaerobic fermentation technology to jointly process municipal sludge

[0038] a. After concentrating the activated sludge in the municipal sludge to a water content of 97% to 98%, it is mixed with fresh elephant grass in a mass ratio of 1:1 to 2:1 for medium-temperature anaerobic fermentation, and the biogas produced is used to prepare bio-natural gas; Solid-liquid separation is carried out on the fermentation residue to obtain biogas residue and biogas slurry; the biogas slurry is returned to the sewage plant for further processing; the waste heat generated by the preparation of bio-natural gas is used to dry elephant grass to obtain dry elephant grass with a moisture content of 25%;

[0039] b. Dewater the primary sludge in the municipal sludge to a water content of 80% to 85%, mix it with the biogas residue obtained in step a at a mass ratio of 3:1, and add the water content obtained in step a to 25% Adjust the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com