Preparation method of carbon nano tube composite coating

A carbon nanotube composite and carbon nanotube technology, which is applied in the field of coating nanomaterials, can solve the problems of limiting the promotion and application of carbon nanotube composite films, the preparation and acquisition of self-assembly methods, and the low assembly efficiency, so as to improve the preparation speed, The effect of easy industrial production and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

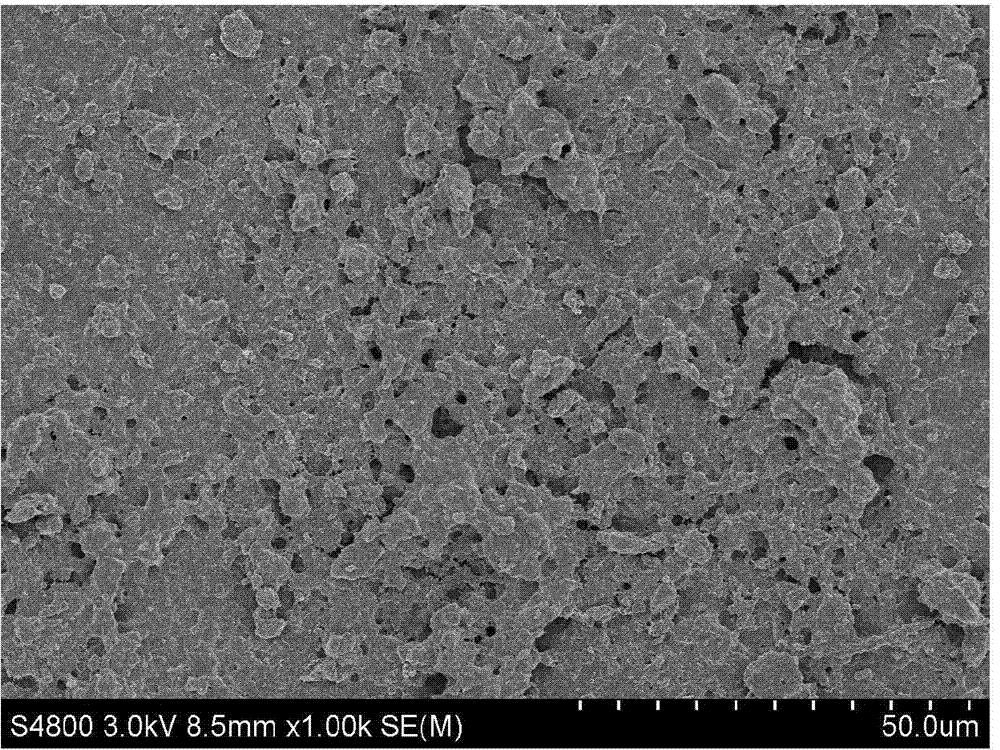

[0045] (1) ultrasonically disperse carbon nanotubes (1 mg / mL) in a solution of 10 mM tris-hydrochloric acid at pH = 8.5, then add one ten-thousandth part of dopamine and stir for 48 hours to obtain polydopamine-modified Dispersion of carbon nanotubes (CNTPDA);

[0046] (2) Add ferric chloride solution (0.1M) to the CNTPDA dispersion to adjust the iron ion concentration to 4.5mM, and adjust the pH to 3 with hydrochloric acid or sodium hydroxide solution to obtain assembly solution A;

[0047] (3) Polyethyleneimine (PEI) was dissolved in deionized water to prepare a 2 mg / mL PEI solution, and the pH was adjusted to 12 with sodium hydroxide to obtain assembly solution B;

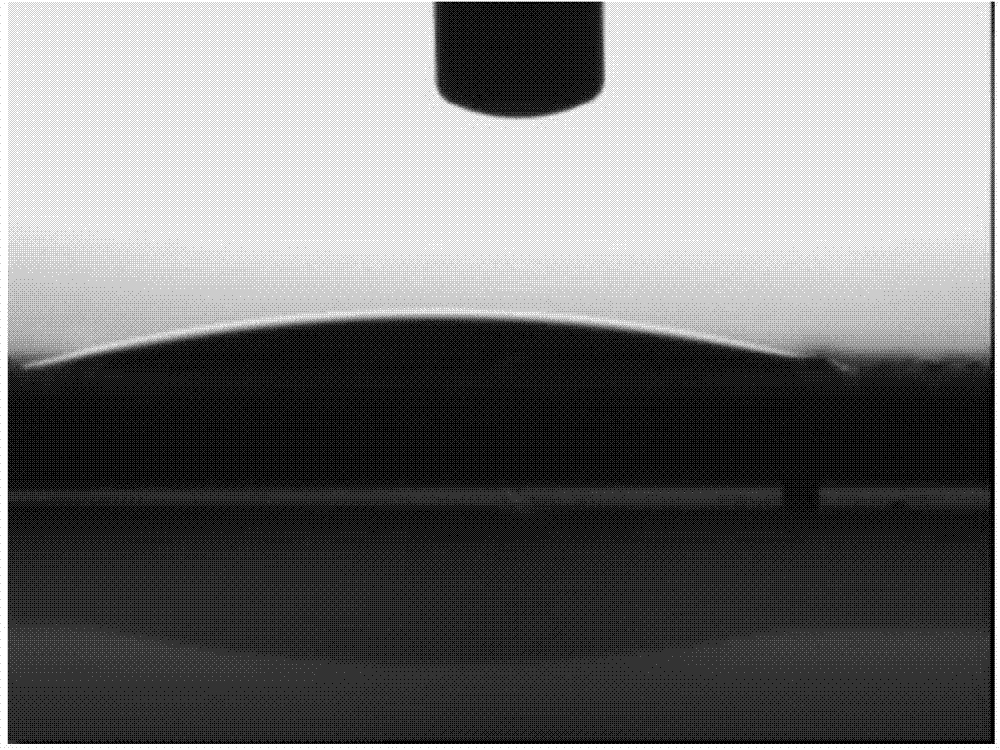

[0048] (4) Place the substrate vertically, install the assembly solution A and the assembly solution B in two hand-held watering cans respectively, control the distance between the nozzle and the substrate to be 10 to 20 cm (subject to the complete coverage of the substrate), and spray the direction perpendicul...

Embodiment 2

[0053] (1) ultrasonically disperse carbon nanotubes (1mg / mL) in a solution of 10mM sodium carbonate-sodium bicarbonate solution at pH=8.5, then add one ten-thousandth part of dopa and stir for 48 hours to obtain polydopamine-modified Dispersion of carbon nanotubes (CNTPDA);

[0054] (2) Add chromium chloride solution (0.1M) to the CNTPDA dispersion to adjust the chromium ion concentration to 2.5mM, and adjust the pH to 3 with hydrochloric acid or sodium hydroxide solution to obtain assembly solution A;

[0055] (3) Polylysine was dissolved in deionized water to form a 1 mg / mL solution, and the pH was adjusted to 12 with sodium hydroxide to obtain assembly solution B;

[0056] (4) Place the substrate vertically, install the assembly solution A and the assembly solution B in two hand-held watering cans respectively, control the distance between the nozzle and the substrate to be 10 to 20 cm (subject to the complete coverage of the substrate), and spray the direction perpendicul...

Embodiment 3

[0060] (1) ultrasonically disperse carbon nanotubes (1 mg / mL) in a solution of 10 mM tris-hydrochloric acid at pH = 8.5, then add one ten-thousandth part of dopamine and stir for 16 hours to obtain polydopamine-modified Dispersion of carbon nanotubes (CNTPDA);

[0061] (2) Add aluminum sulfate solution (0.1M) to the CNTPDA dispersion to adjust the aluminum ion concentration to 4.5mM, and adjust the pH to 4 with hydrochloric acid or sodium hydroxide solution to obtain assembly solution A;

[0062] (3) Dissolving polydiallyldimethylammonium chloride in deionized water to make a 2 mg / mL solution, adjusting the pH to 10 with sodium hydroxide, to obtain assembly solution B;

[0063] (4) Place the substrate vertically, install the assembly solution A and the assembly solution B in two hand-held watering cans respectively, control the distance between the nozzle and the substrate to be 10 to 20 cm (subject to the complete coverage of the substrate), and spray the direction perpendic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com